Concrete corrosion acoustic emission signal data analysis processing system

A technology for data analysis and processing and acoustic emission signals, which is applied in the direction of material analysis, material analysis, and use of acoustic waves/ultrasonic waves/infrasonic waves for material analysis using acoustic wave emission technology, which can solve the problem of heavy workload and poor signal processing , Acoustic emission data processing methods have not been considered, etc., to achieve high work efficiency, speed up data processing, and clear context

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

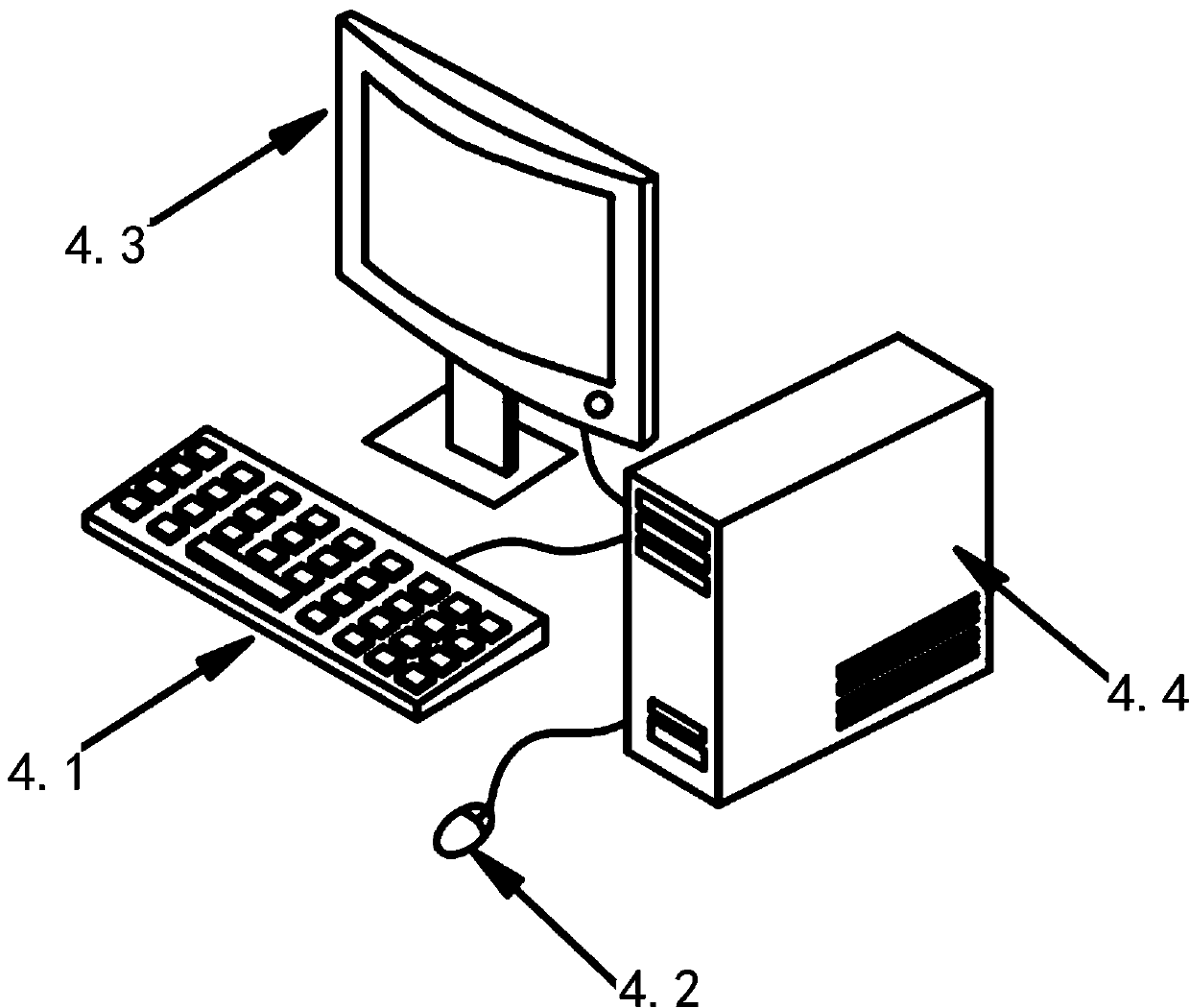

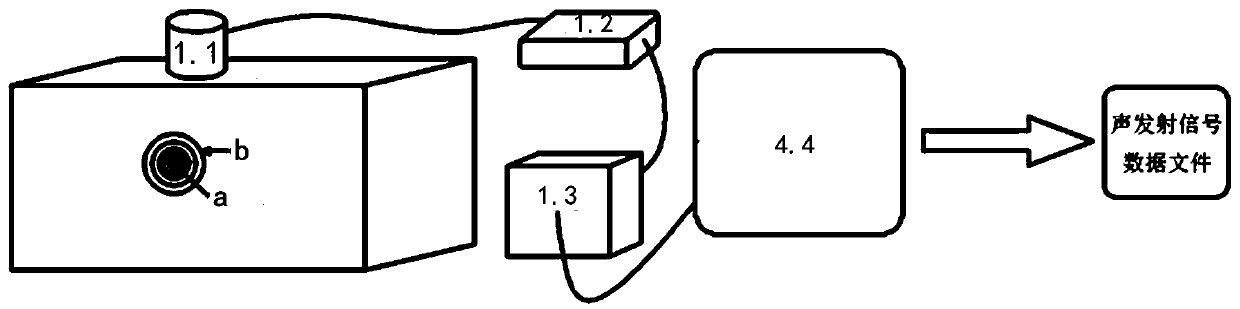

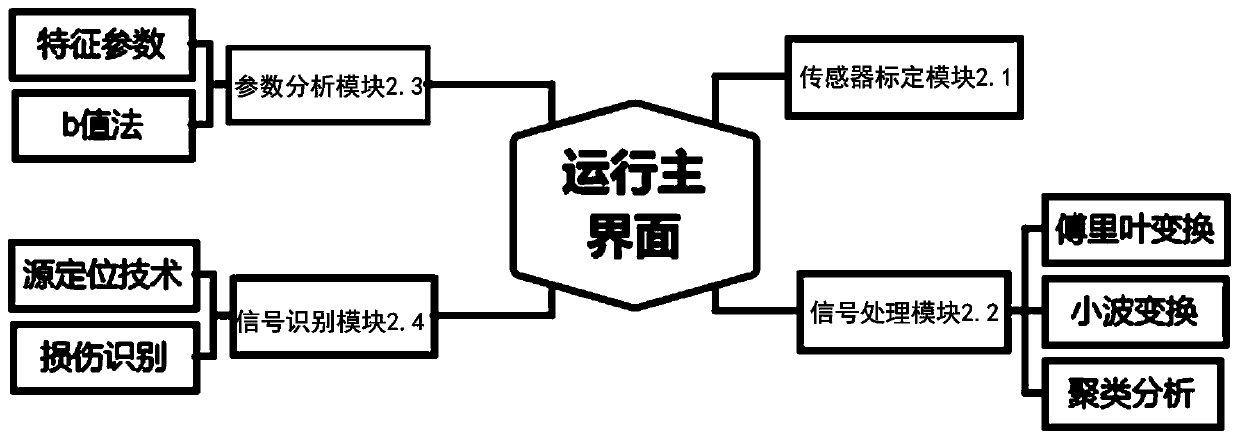

[0025] Such as Figure 1 to Figure 4 As shown, a concrete corrosion acoustic emission signal data analysis and processing system includes:

[0026] The acoustic emission signal acquisition instrument 1 is used for acquiring acoustic emission signal data.

[0027] computer, the computer is installed with a software platform 2 based on matlab, and the software platform 2 based on matlab is used for analyzing and processing the acoustic emission signal data.

[0028] With the help of the powerful data processing capability and graphic display function of the matlab platform, the software can clearly express the calculation results. In order to ensure that the collected waveform is not distorted, the sampling frequency of the acoustic emission sensor is 10-50MHz, and the amount of acoustic emission signal data collected per minute is usually between 6×107 and 3×108, and only one power-on in the concrete dry-wet cycle It takes 2 to 3 minutes to accelerate the corrosion process. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com