Thin-walled component machining magneto-rheological flexible fixture device

A thin-walled component and flexible fixture technology, applied in the mechanical field, can solve the problems of low adjustability of magnetic field strength, limited magnetic field strength, and inability to hold workpieces, and achieve good adjustability, controllable magnetic field size, and magnetic field. Effects with a wide range of strengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

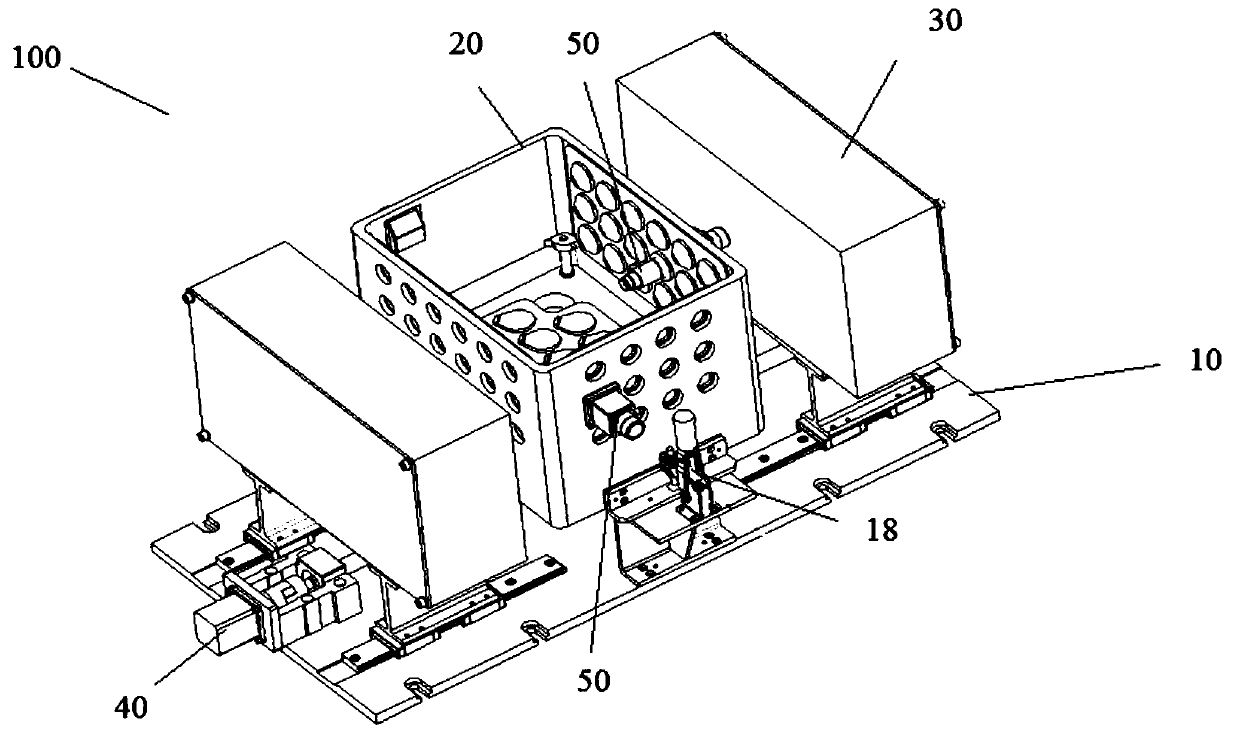

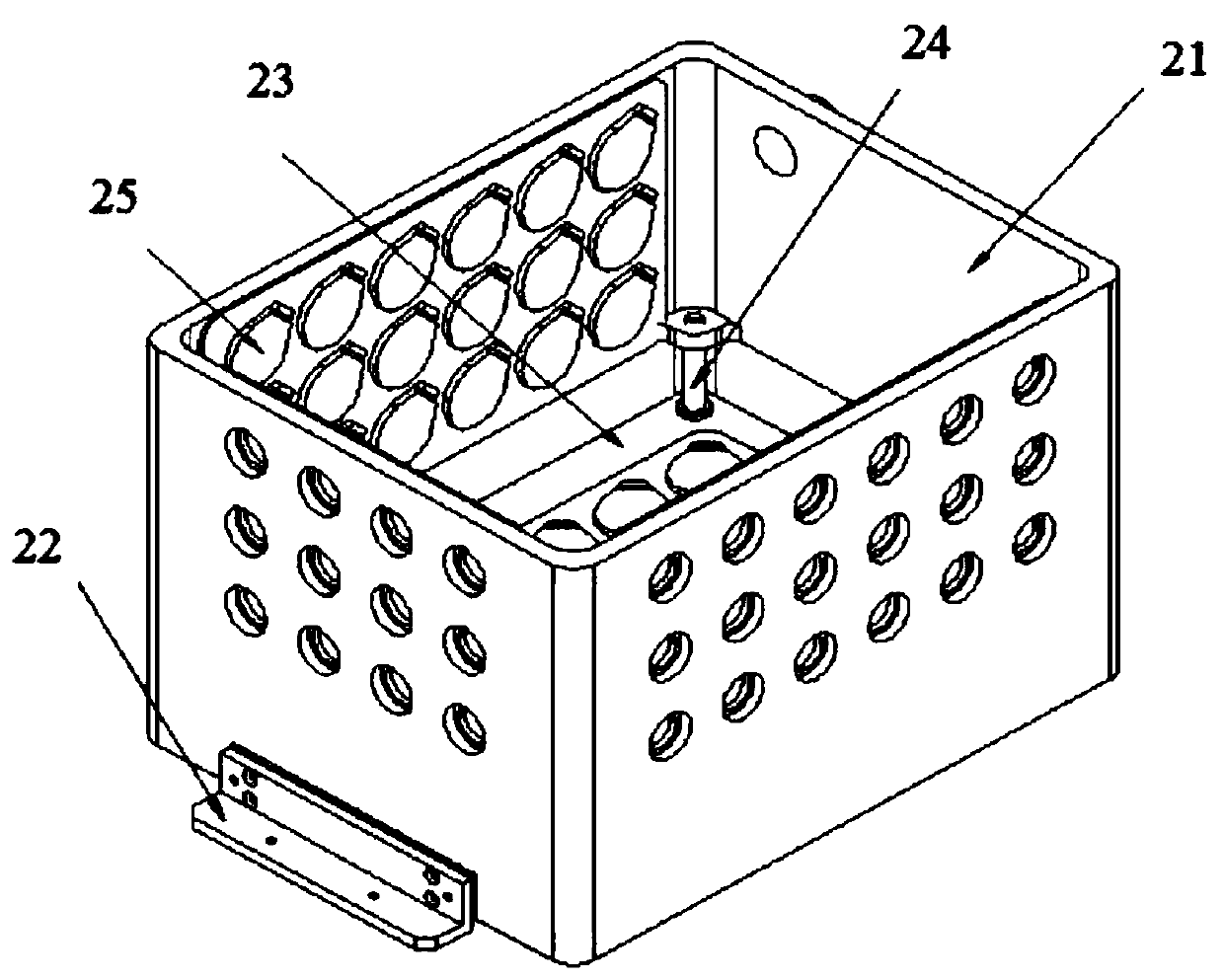

[0020] figure 1 It is the overall structure diagram of the magnetorheological flexible fixture device for processing thin-walled components in the embodiment of the present invention.

[0021] Such as figure 1 As shown, the magnetorheological flexible fixture device 100 for processing thin-walled components in this embodiment is used to clamp thin-walled components, and has a base assembly 10, a magnetorheological fluid container 20, and multiple side box assemblies 30 , a plurality of ball screw assemblies 40 and a control unit.

[0022] The control unit is communicated with a computer.

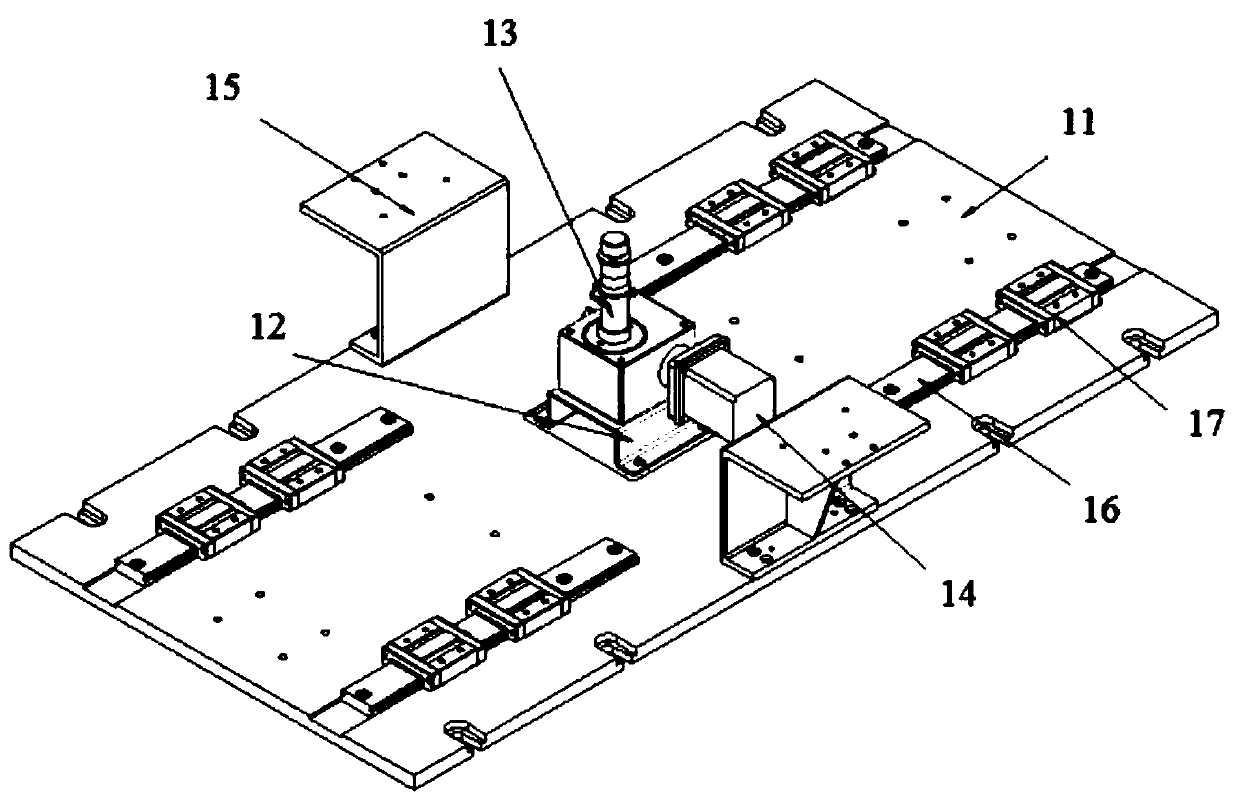

[0023] figure 2 It is a structural schematic diagram of the base assembly in the embodiment of the present invention.

[0024] Such as figure 2 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com