Novel composite board and preparation method thereof

A composite board, a new type of technology, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problems of strength and hardness constraints, waste of resources, easy to be scratched on the surface, etc., to overcome the strength and hardness. Effects of hardness, counterfeiting resistance, flexibility on-demand material selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

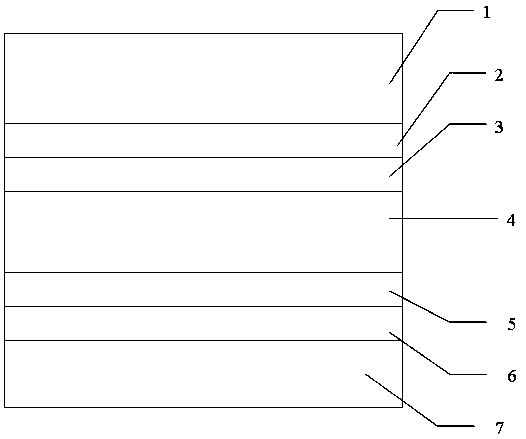

[0026] Reference attached figure 1 , A new type of composite board provided by the present invention is composed of a board-shaped base material 4 and a composite layer.

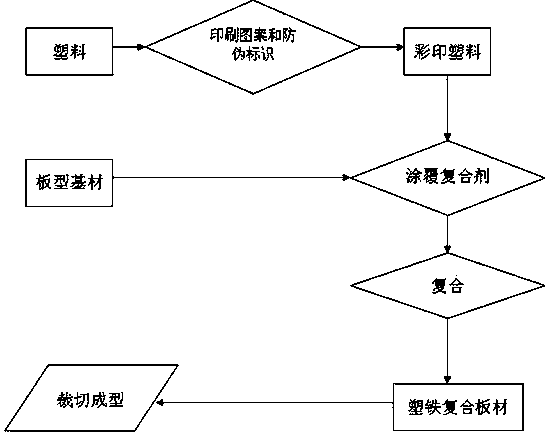

[0027] The composite layer is symmetrically composited on the upper and lower surfaces of the board-shaped substrate 4, and is composed of an adhesive layer 3 (or 5), a color printing layer 2 (or 6) and a plastic layer 1 (or 7). Wherein, the color printing layer 2 (or 6) is to print the required patterns or anti-counterfeiting marks on the bottom surface of the plastic layer 1 (or 7). Since the plastic layer 1 (or 7) generally adopts a transparent plastic film, its glossy And permeability can enhance the printing effect, obtain beautiful patterns, and prevent the anti-counterfeiting marks from being replaced or damaged. Described bonding layer 3 or (5) is the adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com