A kind of preparation method of neoprene latex with good dry stickiness

A technology of neoprene latex and dry bonding, which is applied in the direction of chloroprene adhesives, adhesives, adhesive types, etc., can solve the problems of reduced performance and lower stability of neoprene latex, and achieve good stability, High crystallinity, white color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

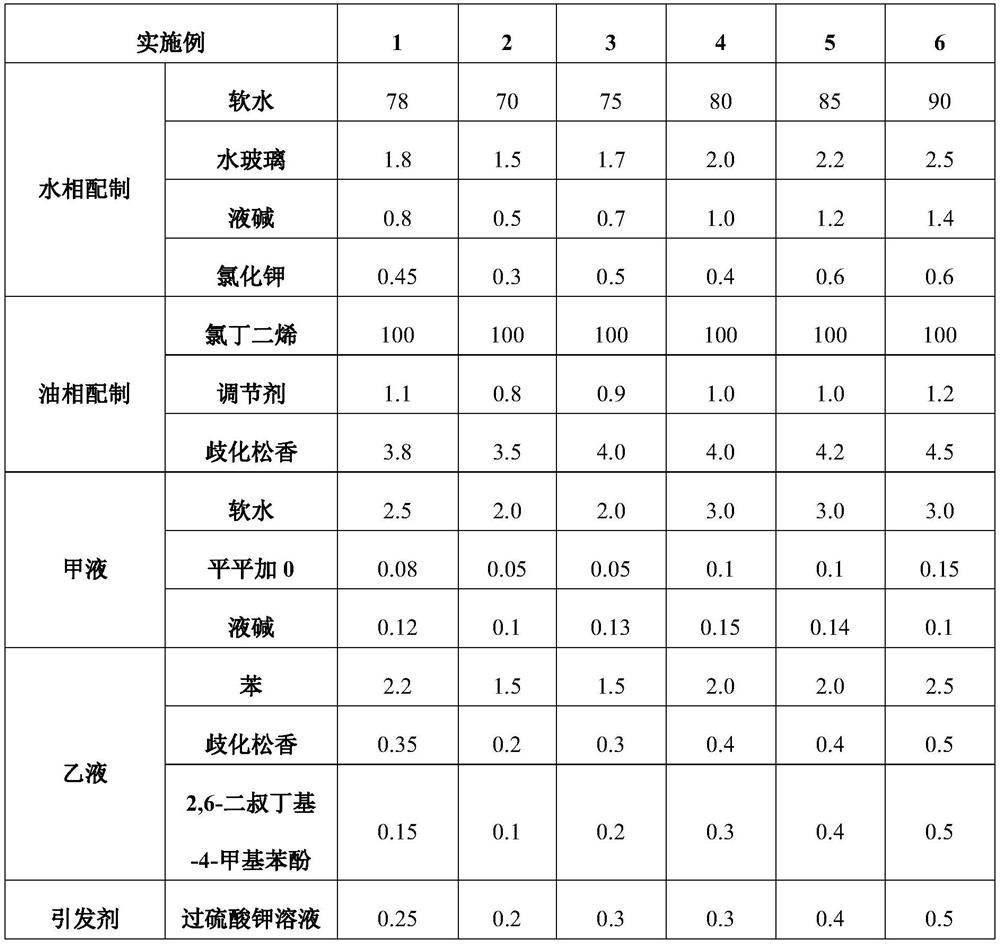

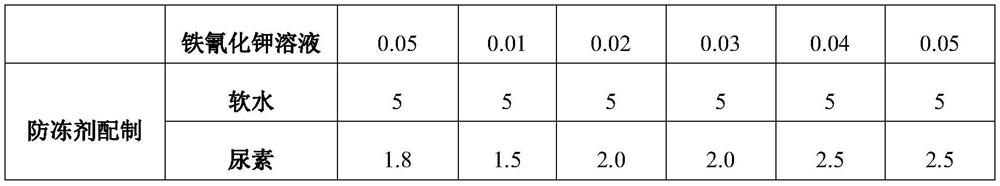

Examples

preparation example Construction

[0042] A kind of preparation method of the neoprene latex with good dry stickiness, comprises the following steps:

[0043] A. Water phase preparation

[0044] Add soft water to the water phase preparation tank, add water glass, sodium hydroxide, and potassium chloride to the soft water sequentially under stirring, and use a pump to circulate at the same time, so that the additives are completely dissolved in the soft water to obtain an aqueous phase liquid. Then take a sample and analyze it until it is qualified, and set it aside.

[0045] Start the water phase pump to transport the prepared water phase liquid to the water phase metering tank. When the required amount is reached, close the water phase feeding cock, stop the pump, and then use steam to raise the temperature to 26-30°C, and then make up the dilution water ( Including steam condensed water), to ensure the effect of emulsification and improve the utilization rate of the water phase preparation tank.

[0046] B....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com