Winding-type seed cotton special fiber cleaning machine having laser cutting function

A laser cutting and winding technology, which is applied in fiber processing, laser welding equipment, welding/welding/cutting items, etc., can solve the problems of low overall efficiency, complex machine structure, and slow down processing speed, so as to improve processing efficiency, The overall structure is simple and the effect of saving machine cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described in detail below with reference to the drawings and specific embodiments.

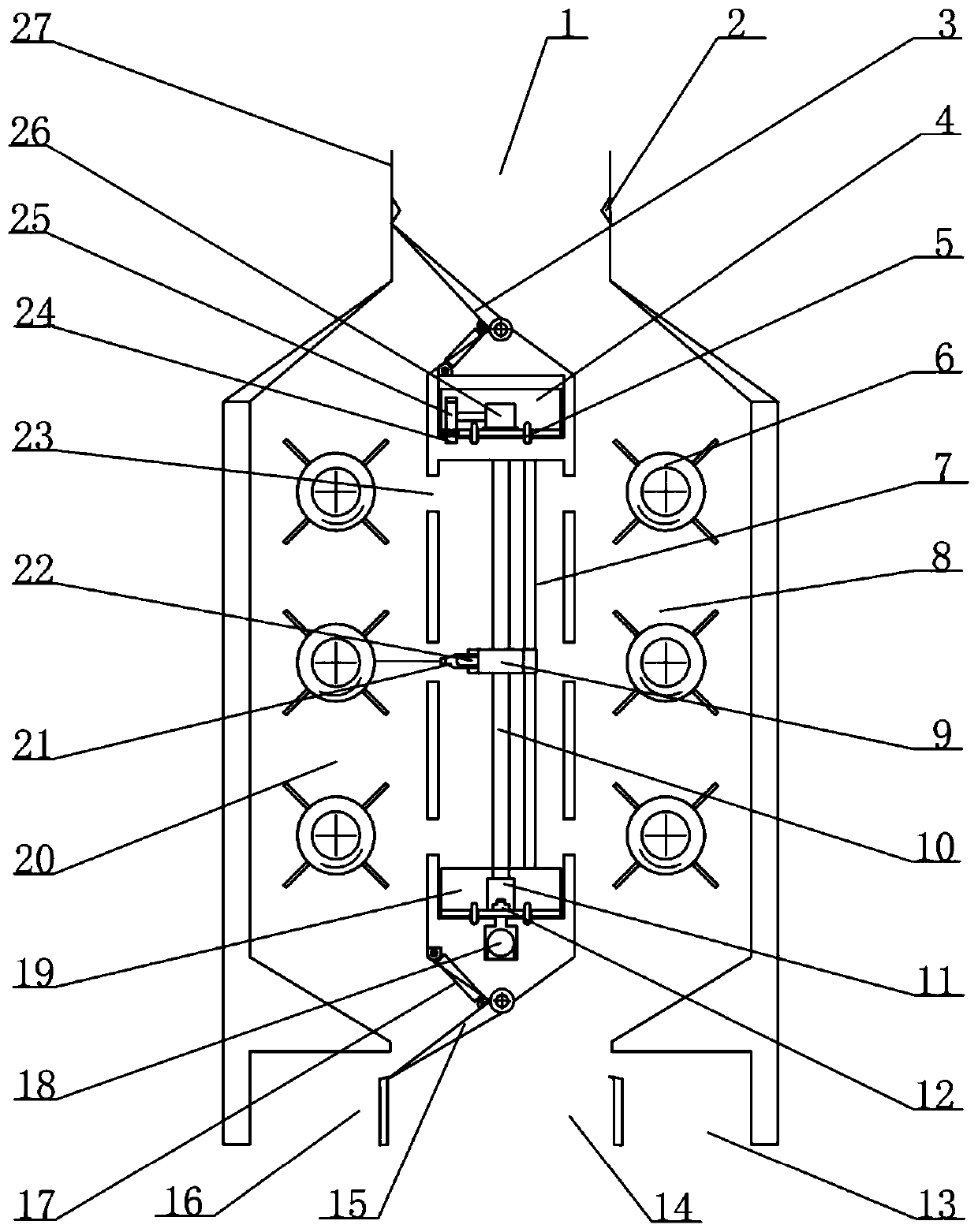

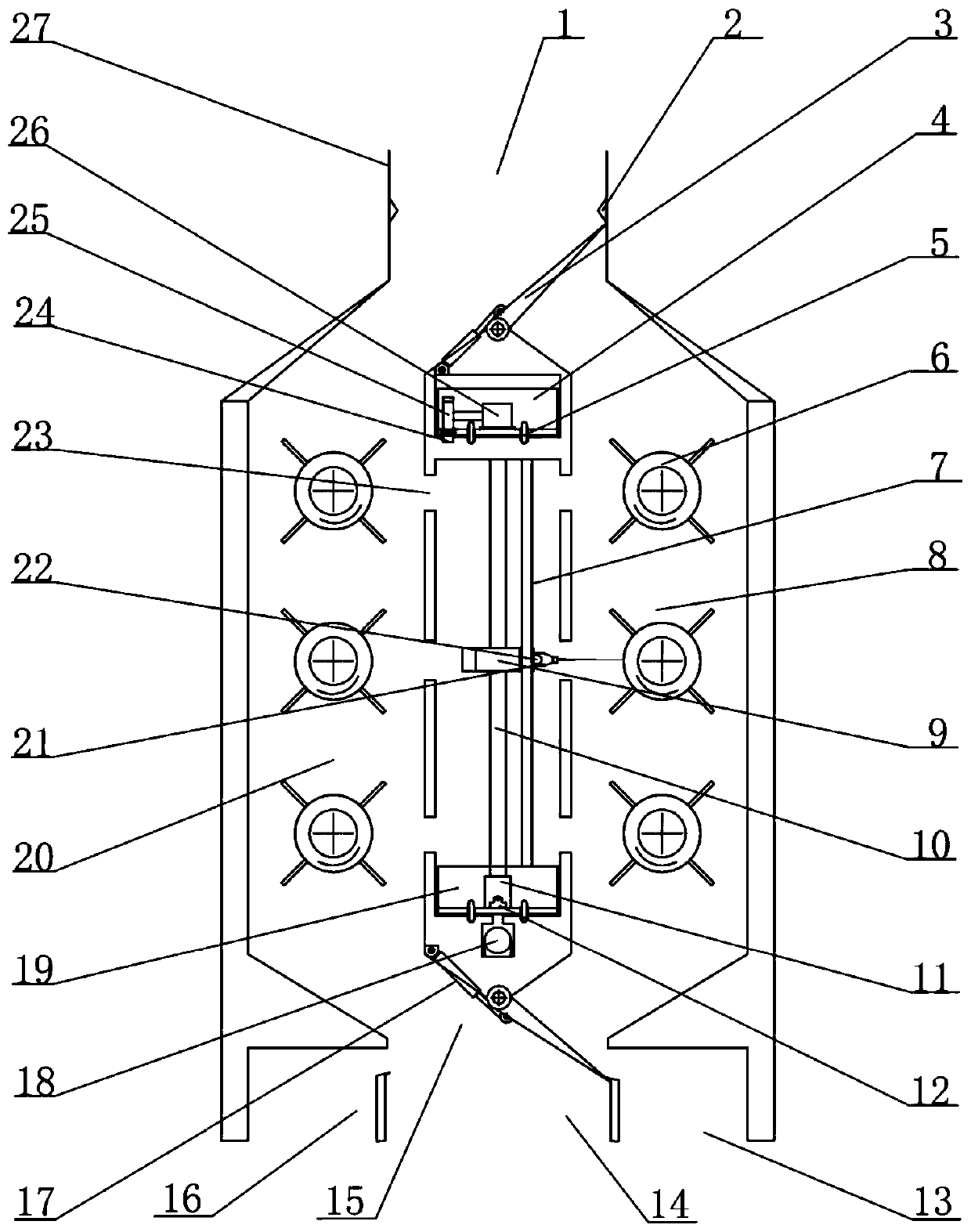

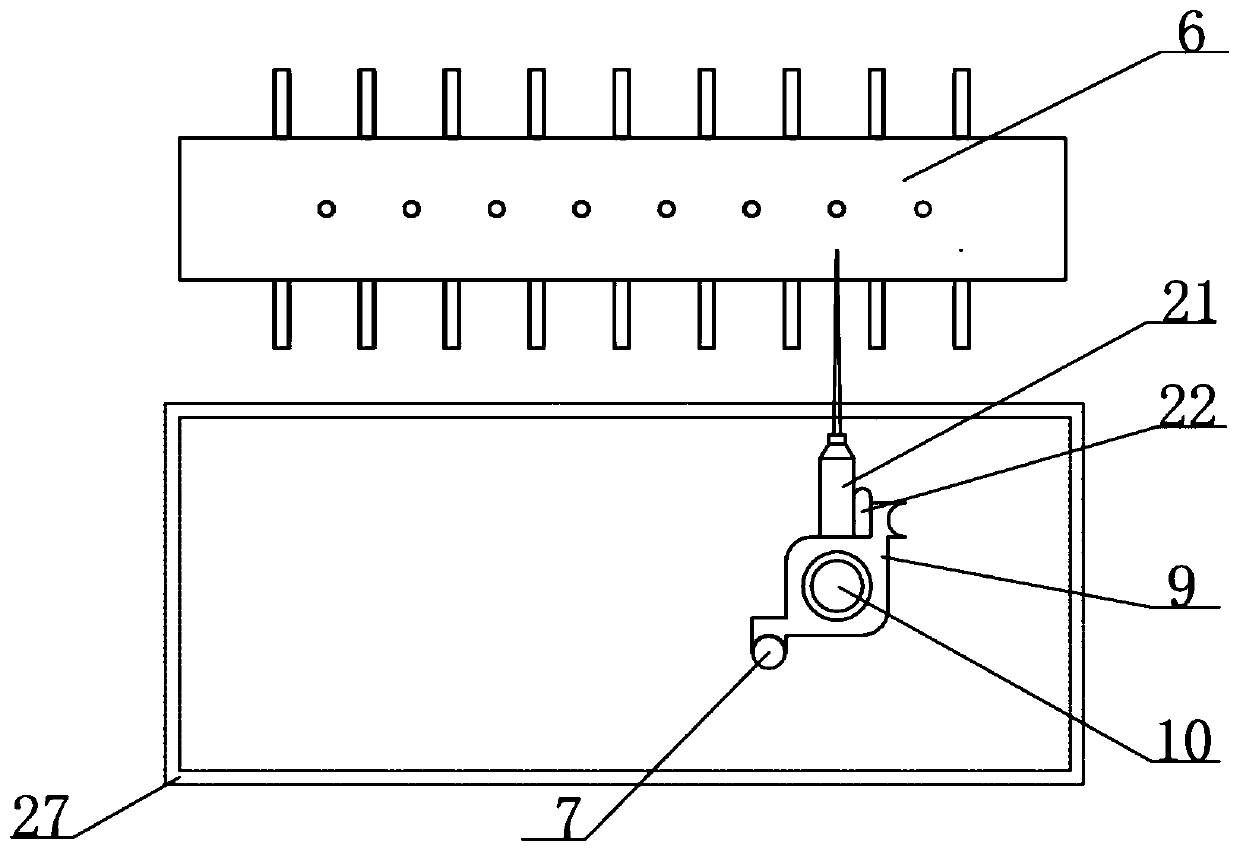

[0018] Such as figure 1 and figure 2 Shown is a schematic diagram of the structure of the present invention, including the machine housing (27), the seed cotton feed inlet (1), the right side foreign fiber winding cleaning chamber (8), the left foreign fiber winding cleaning chamber (20), and the right side Foreign fiber discharge port (13), foreign fiber discharge port (16) on the right side, and seed cotton discharge port (14);

[0019] The seed cotton feed port (1) is located at the uppermost end of the machine housing (27). A pair of stoppers (2) and an upper rotating baffle (3) are provided directly below the seed cotton feed port (1). 2) It is used to block the top of the rotating baffle (3) to prevent the seed cotton from getting stuck on the baffle (3) when the seed cotton falls; the upper rotating baffle (3) is used to control the direction of the seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com