Processed cheese and preparation method thereof

A technology for processed cheese and natural cheese, which is applied in the field of processed cheese and its preparation, and can solve problems such as undiscovered cheese

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

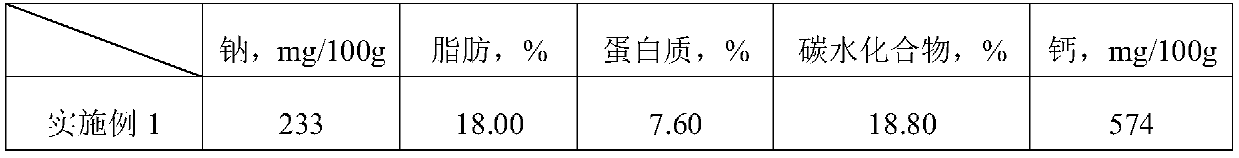

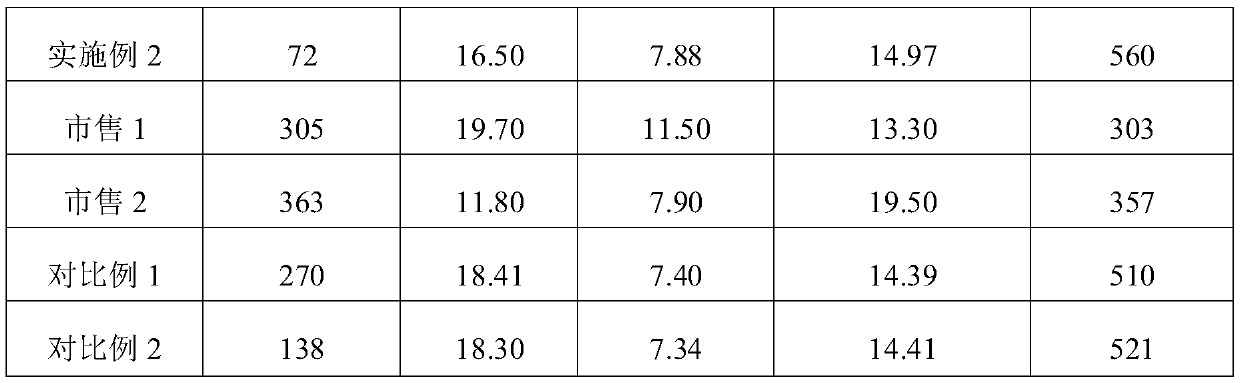

Embodiment 1

[0079] Ingredients: 9% mature cheddar cheese; 9% full-fat curd; 9% unsalted butter; 12% chilled cream; 12% white sugar; 3% skimmed milk powder; 1.4% protein powder CH7694; 1.4% protein powder 852B; 1% heavy calcium carbonate; 0.5% complex emulsifying salt; 0.5% stabilizer (xanthan gum: carrageenan: locust bean gum = 1:1:1); 0.03% vanilla extract; 0.03% butter essence; 0.08 % potassium sorbate; 41.06% water.

[0080] How to make processed cheese:

[0081] (1) Melt and mix the above raw materials: Stir and mix all the raw materials evenly. The stirring speed of pre-mixing is 500r / min, the stirring speed after pre-mixing is 1500r / min, and the melting temperature is 95°C.

[0082] (2) Homogenize while hot, with a homogenization pressure of 115 bar; after homogenization, pasteurize at a temperature of 95° C. for 5 minutes.

[0083] (3) The filling temperature is 82°C. After filling, the product is cooled and stored in a cold storage at 0-5°C.

[0084] Wherein, the preparation p...

Embodiment 2

[0103] Ingredients: 18% full-fat curd; 9% unsalted butter; 12% frozen cream; 12% white sugar; 3% skimmed milk powder; 1.4% protein powder CH7694; 1.4% protein powder 852B; 1% heavy carbonic acid Calcium; 0.5% complex emulsifying salt; 0.5% stabilizer (xanthan gum: carrageenan: locust bean gum = 1:1:1); 0.03% vanilla extract; 0.03% butter essence; 0.08% potassium sorbate; 41.06% water.

[0104] The preparation method of processed cheese, the preparation process of full-fat curd block, and the preparation process of butter essence are all the same as in Example 1.

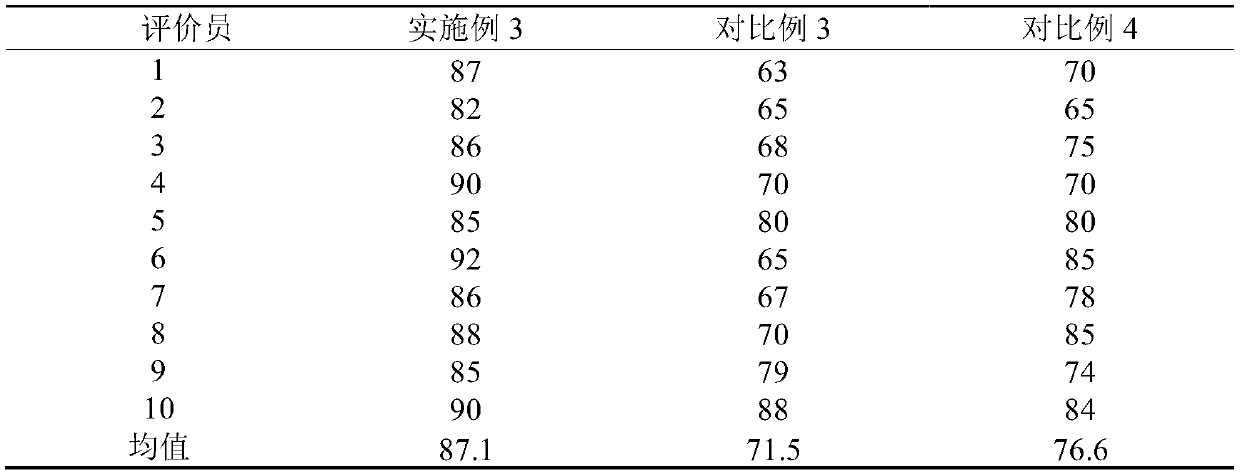

Embodiment 3

[0106] Ingredients: 9% mature cheddar cheese; 9% full-fat curd; 9% unsalted butter; 12% chilled cream; 12% white sugar; 3% skimmed milk powder; 1.4% protein powder CH7694; 1.4% protein powder 852B; 1% heavy calcium carbonate; 0.5% complex emulsifying salt; 0.5% stabilizer (xanthan gum: carrageenan: locust bean gum = 1:1:1); 0.06% butter essence; 0.08% potassium sorbate; 41.06 %water.

[0107] The preparation method of processed cheese, the preparation process of full-fat curd block, and the preparation process of butter essence are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com