Rotary pressing type vacuum flask

A vacuum bottle and push-type technology, which is applied to the types of packaging items, applications, special packaging items, etc., can solve problems such as inconvenient use, achieve the effect of preventing accidental pressing and improving the user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

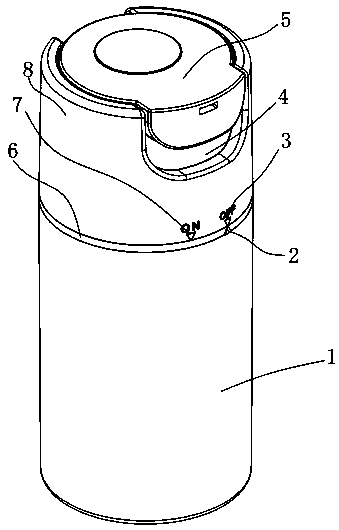

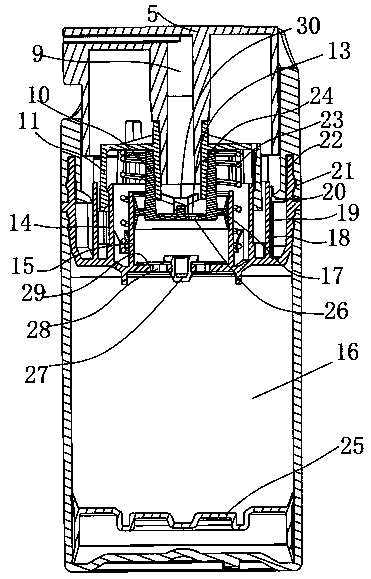

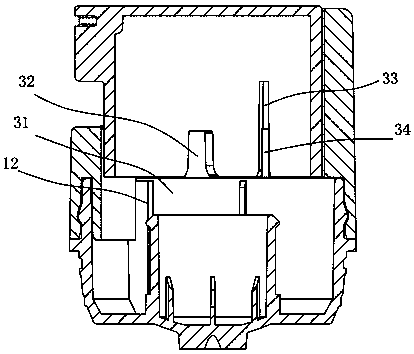

[0022] Embodiment: A rotary press type vacuum bottle, comprising a bottle body 1, a shoulder cover 6 arranged on the top of the bottle body 1, a bottle cap 8 arranged on the shoulder cover 6, and a bottle cap 8 arranged on the bottle cap 8 button 5, the bottle body 1 is provided with a material chamber 16 with an open top, and the material chamber 16 is provided with a large piston 25 that moves up and down along the material chamber 16, and the center of the shoulder sleeve 6 is provided with a pumping cylinder 15 , the pumping cylinder 15 is provided with a small piston 17 that moves up and down along the pumping cylinder 15, and the bottom of the pumping cylinder 15 is provided with a feed port 28 communicating with the material cavity 16, and the feed hole A feed check valve is provided on the top, and the opening direction of the feed check valve points to the pumping cylinder 15. The center of the small piston 17 is provided with a discharge port 26 that runs through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com