Optical fiber coupling and welding device for butterfly laser device

A technology of optical fiber coupling and welding device, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of low packaging precision and low packaging efficiency, and achieve the improvement of quality, packaging efficiency and reasonable structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

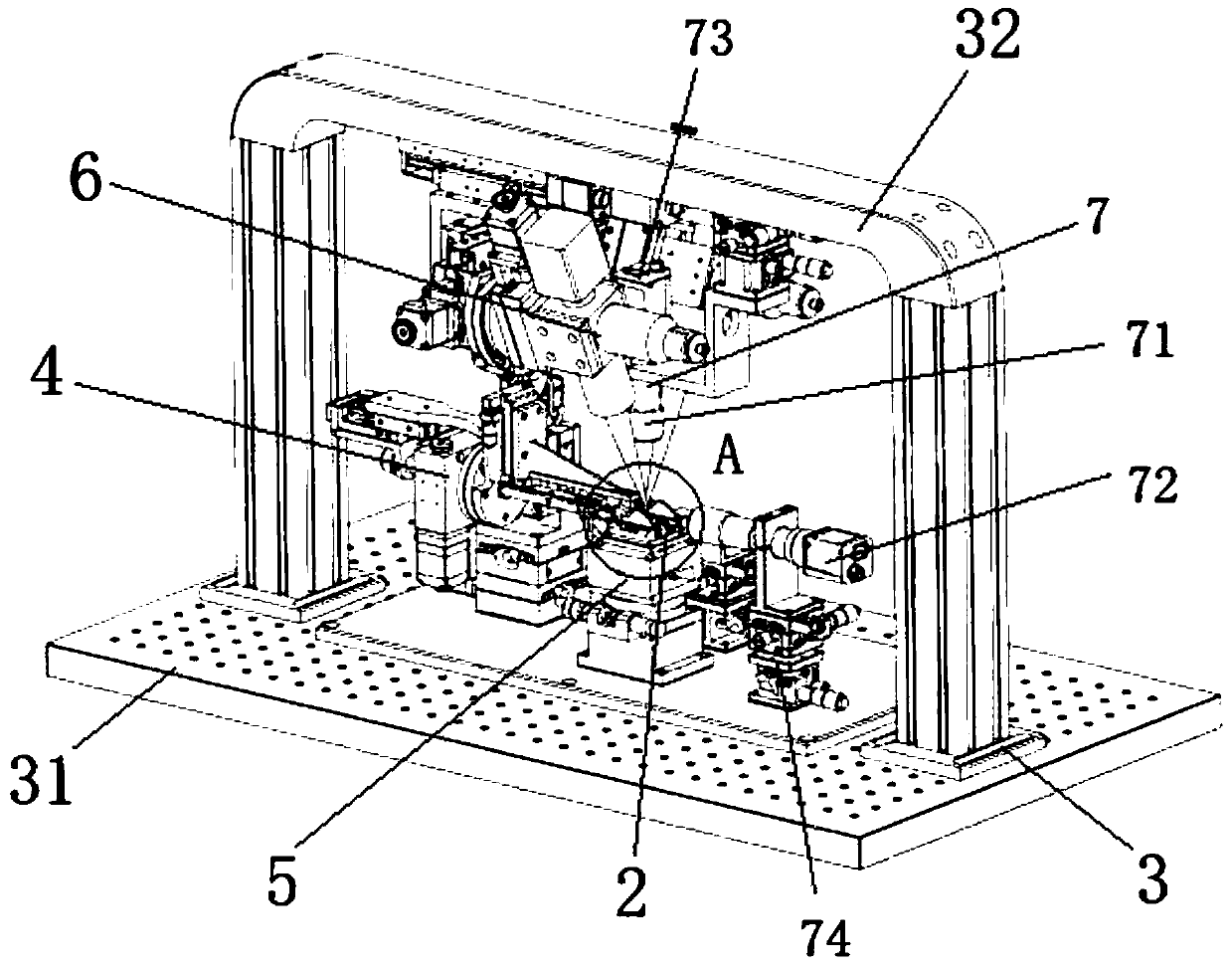

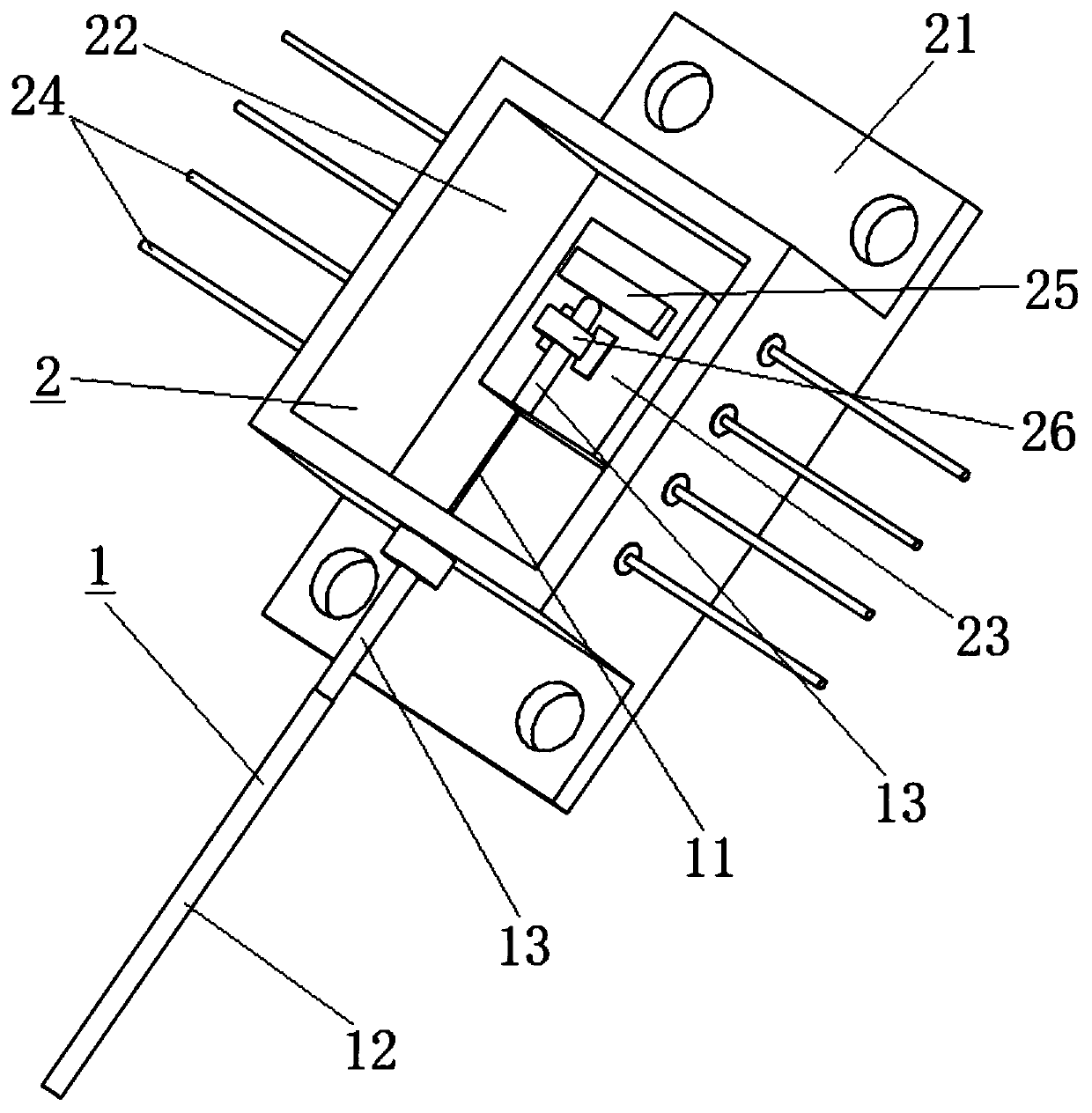

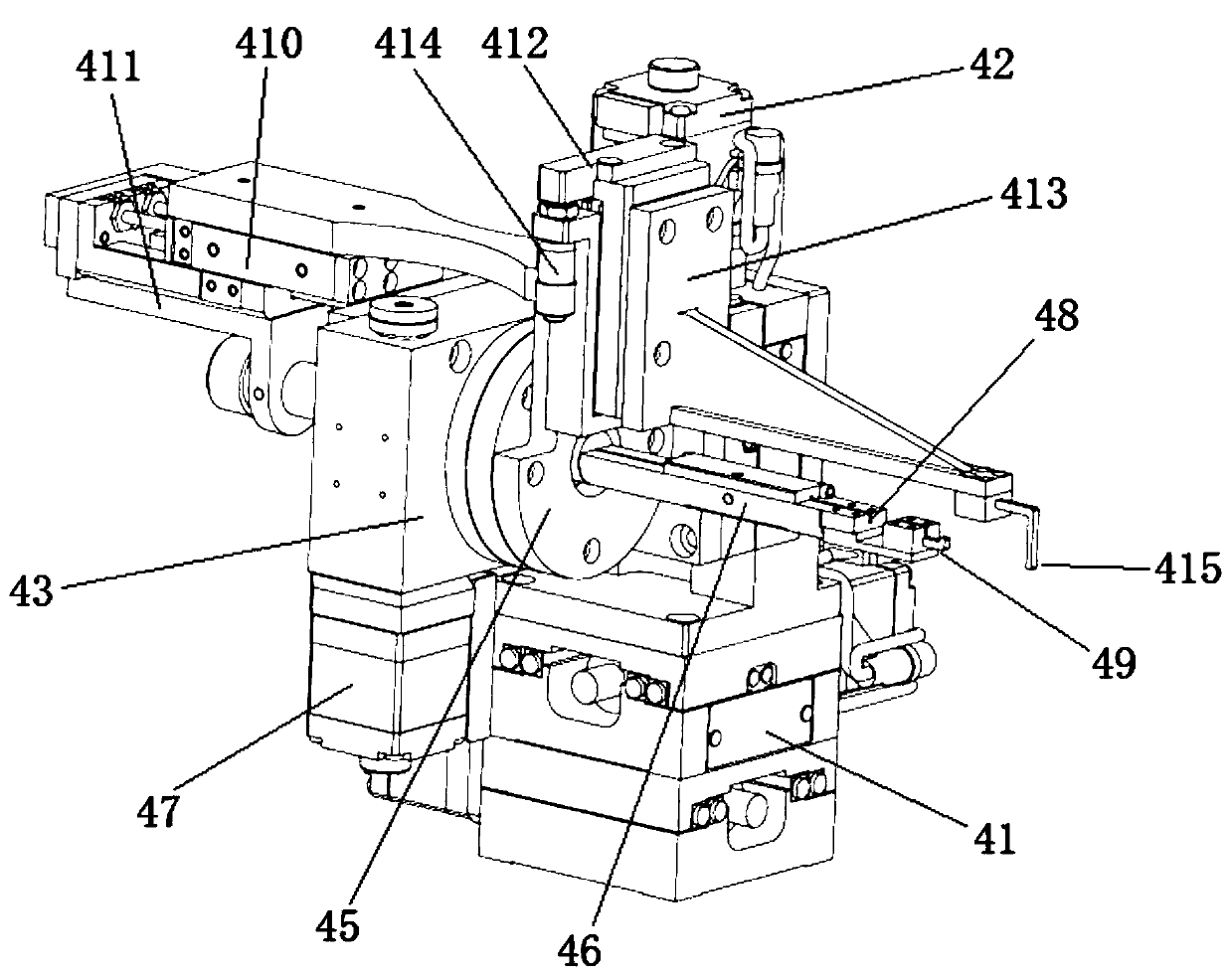

[0038] Aiming at the problems that the existing butterfly laser packaging process mainly relies on mutually isolated devices and is completed by manual operation, the packaging efficiency is low and the packaging precision is not high, the invention provides a butterfly laser fiber coupling and welding device. Wherein the optical fiber 1 to be packaged includes a fiber front end 11 and a fiber tail end 12, a metal sleeve 13 is sleeved at the fiber front end and the fiber tail end, and the casing 2 is butterfly-shaped, including a bottom plate 21, on which the bottom plate 21 is arranged. The box body 22, the heat sink 23 arranged in the box body 22 and the pins 24 used for power-on are arranged on both sides of the box body 22, and a chip 25 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com