Manufacturing process of enamel container and enamel container

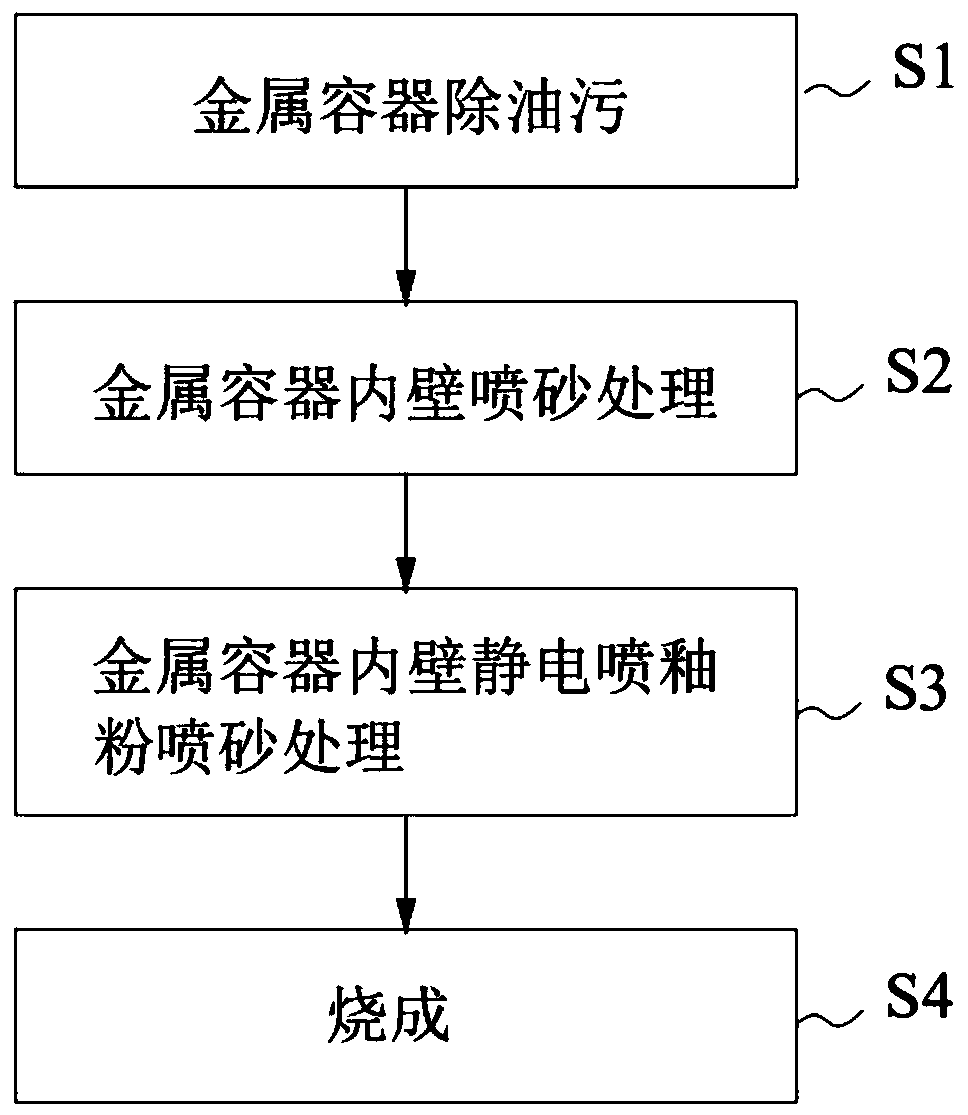

A production process and container technology, which is applied in the direction of manufacturing tools, metal processing equipment, coatings, etc., can solve the problems that the glaze slurry cannot be uniformly coated, the thickness of the enamel is uneven, and the working time is occupied, so as to improve the efficiency of powder coating, The effect of uniform thickness of enamel and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The metal container of this embodiment is a stainless steel container with a height of 10 cm and a cylindrical side wall. The stainless steel container was placed in a heating furnace and heated for 30 minutes at a heating temperature of 400°C. After the stainless steel is cooled, the inner wall of the stainless steel container is sandblasted with No. 46 emery. The air pressure for sandblasting is 0.6MPa and the sandblasting time is 35s. The roughness of the inner wall of the stainless steel container was detected to be Ra2. The electrostatic spray glaze powder process includes the following steps:

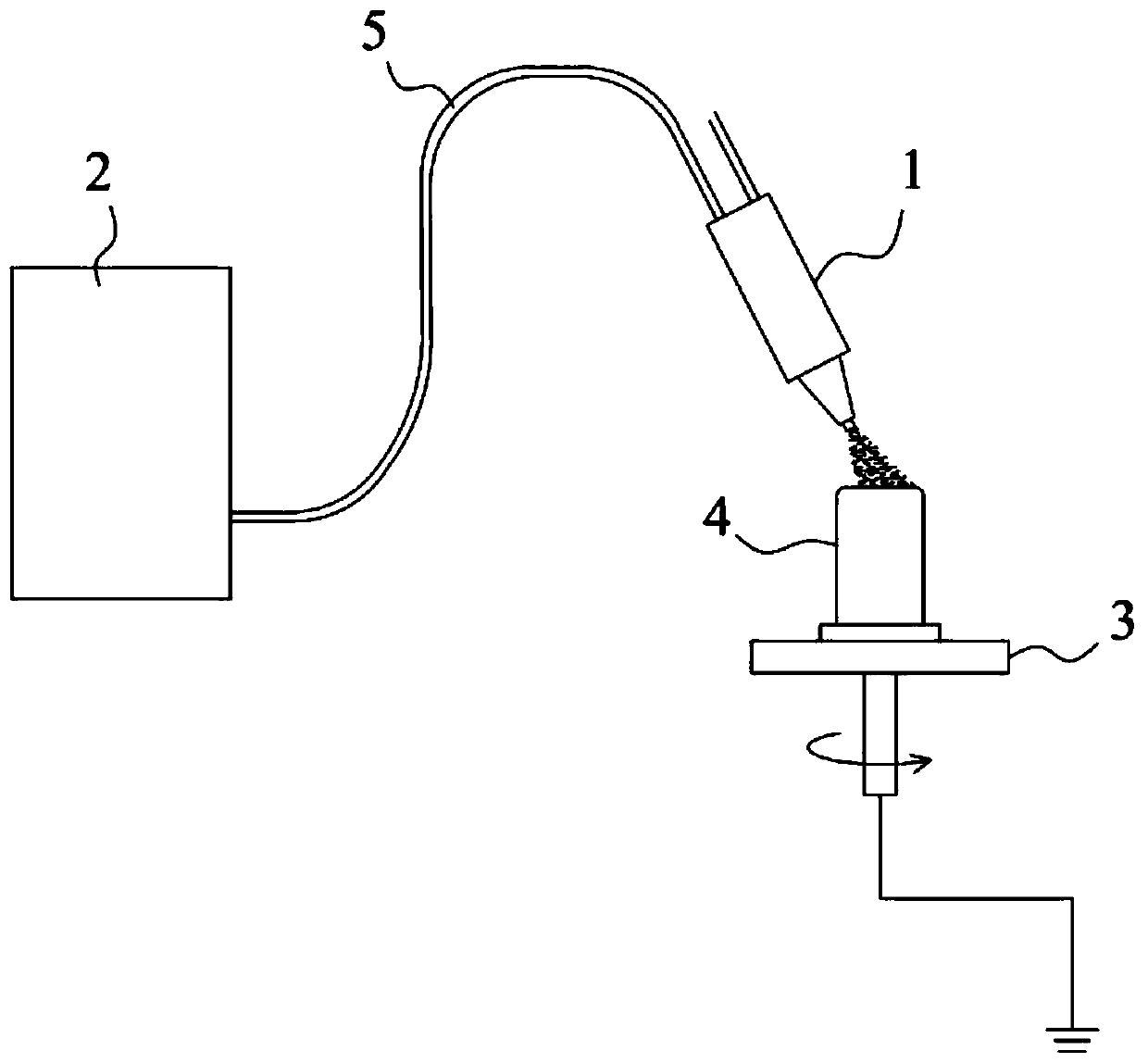

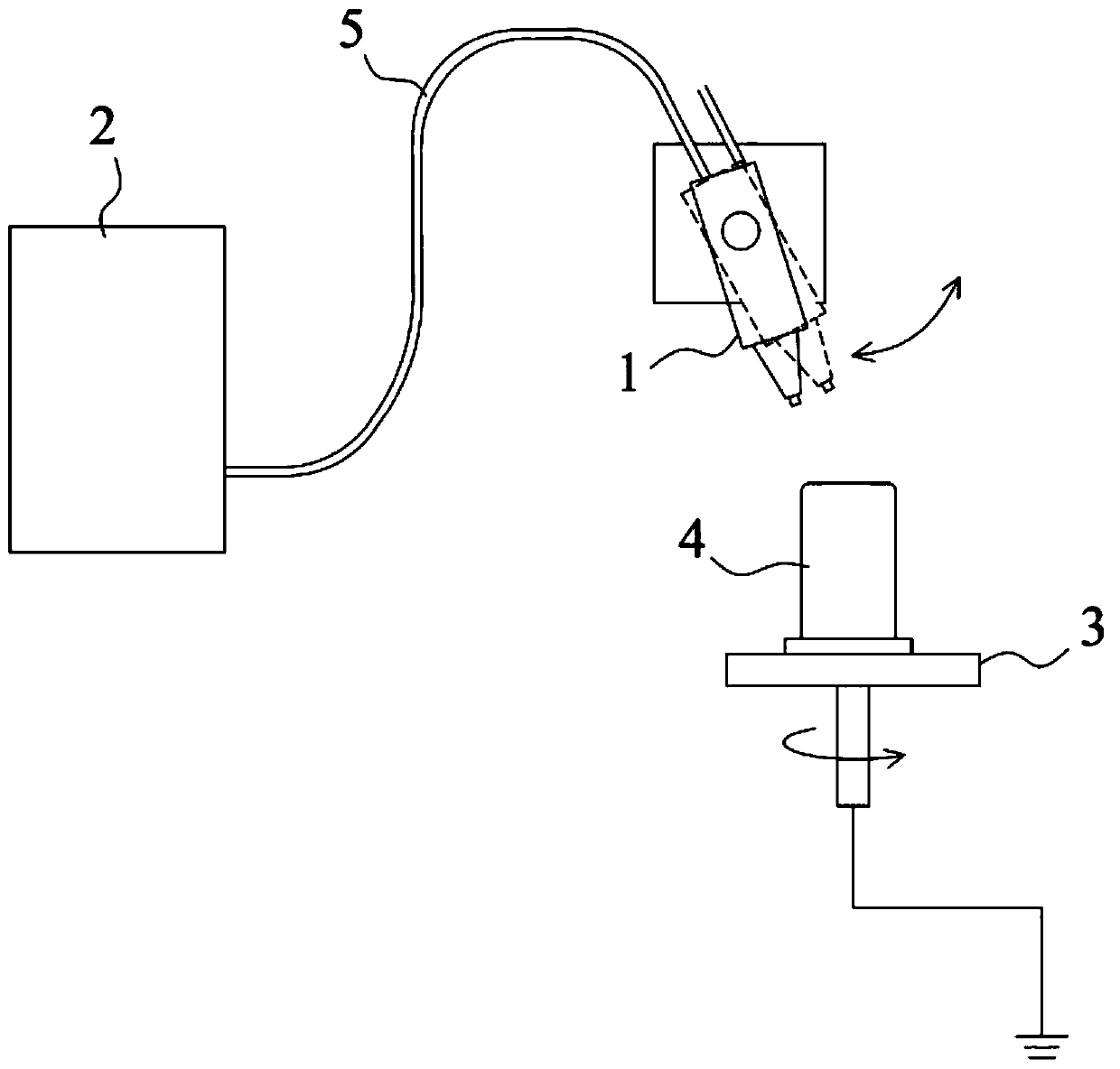

[0037] S311: Provide an electrostatic spray powder system for enamel containers, which includes an electrostatic spray gun and a rotating carrier;

[0038] S312: Fix the metal container on the carrier, the metal container is electrically connected to the carrier, and the carrier is grounded;

[0039] S313: Adjust the inclination angle of the electrostatic spray gun so that the ...

Embodiment 2

[0044] The metal container of this embodiment is a stainless steel container with a height of 20 cm and a cylindrical side wall. The stainless steel container was placed in a heating furnace and heated for 30 minutes at a heating temperature of 450°C. After the stainless steel is cooled, the inner wall of the stainless steel container is sandblasted with No. 46 emery. The air pressure for sandblasting is 1MPa, and the sandblasting time is 50s. The roughness of the inner wall of the stainless steel container was detected to be Ra3.2. The electrostatic spray glaze powder process includes the following steps:

[0045] S321: Provide an electrostatic spray powder system for enamel containers, which includes an electrostatic spray gun and a rotating carrier;

[0046] S322: Fix the metal container on the carrier, the metal container is electrically connected to the carrier, and the carrier is grounded;

[0047] S323: Adjust the inclination angle of the electrostatic spray gun so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com