Electrolysis deplating solution and method for removing copper layer and tin layer on hanging tool simultaneously

A technology for deplating solution and copper layer, which is applied in the direction of electrolytic process and electrolytic components, etc. It can solve the problems of easy damage to the substrate, long deplating time of chemical deplating method, poor deplating effect, etc., and achieves efficient deplating, Improve the effect of deplating and reduce the effect of deplating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

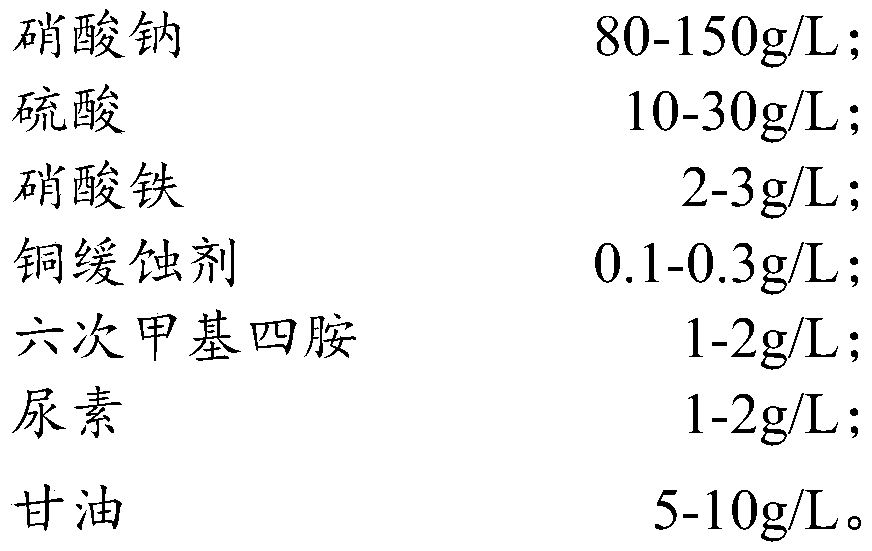

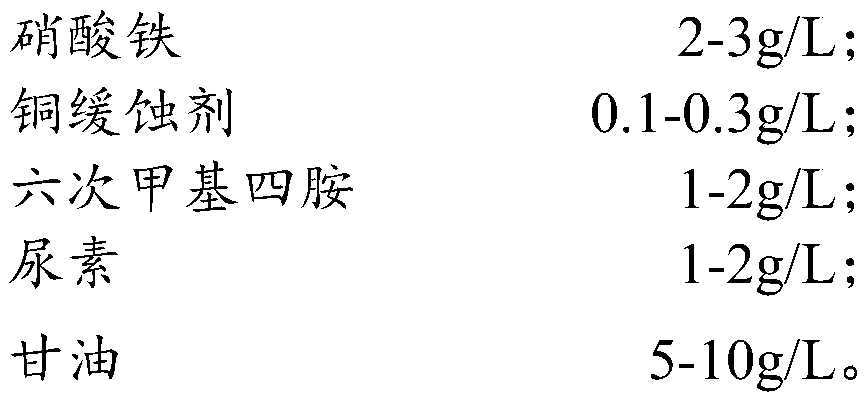

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, rather than all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative work all belong to the protection scope of the present invention.

[0025] With the continuous advancement of science and technology, electronic products are also constantly changing, and the PCB board, which is the carrier of the electrical connection of electronic components, is also constantly being updated. However, in the PCB electroplating process, due to the tip effect of the current, very thick copper plating and / or tin plating will be formed on the conductive part of the stainless steel hanger, which brings great inconvenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com