An Ultra-High Temperature Miniature Fiber Optic EFPI Strain Sensor

A strain sensor, ultra-high temperature technology, applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problems of increasing system complexity, temperature cross-sensitivity, limited installation space, etc., to meet the requirements of narrow space measurement demand, size reduction, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

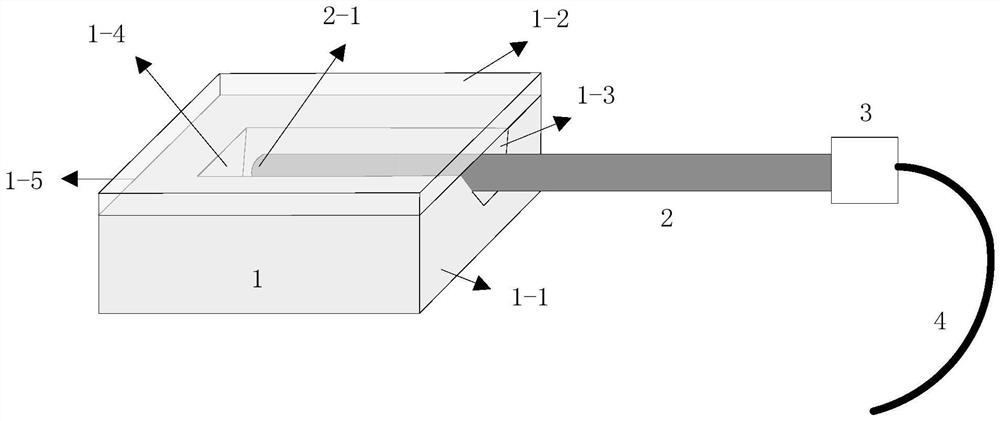

[0037] In this example, SiC chips and gold-plated optical fibers are used to construct such figure 1 The ultrahigh temperature miniaturized fiber optic EFPI strain sensor shown.

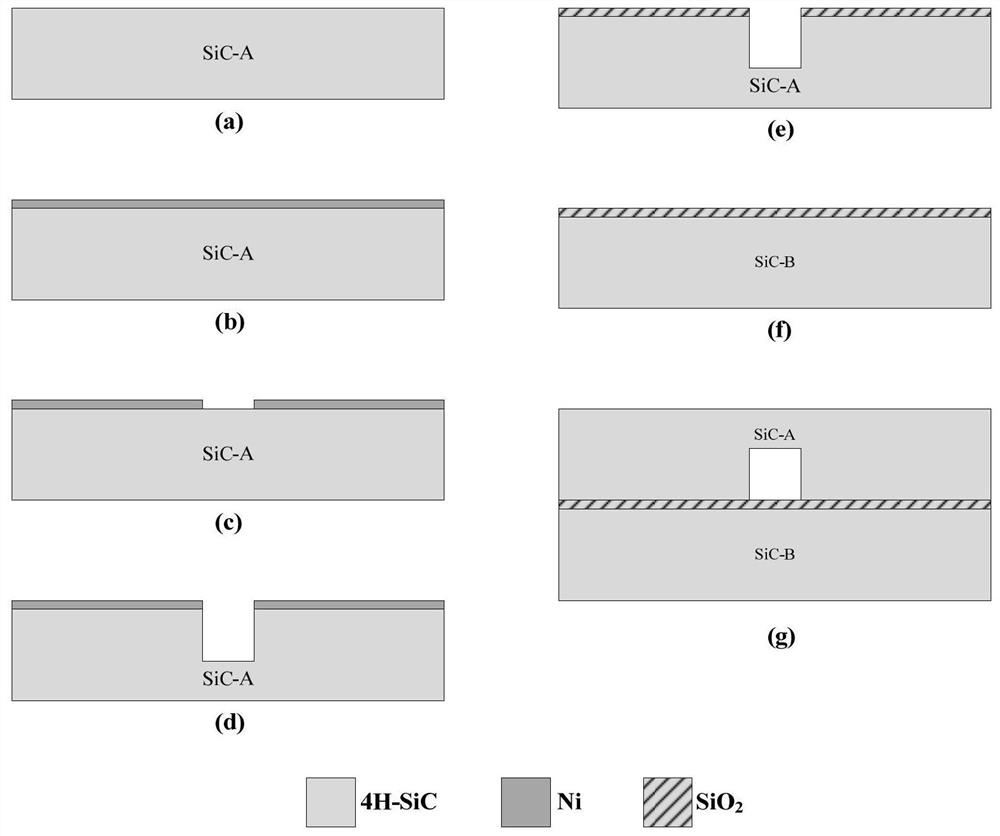

[0038] The SiC chip 1 is prepared by MEMS technology, the size is less than 3mm×3mm, and the thickness is only about 700μm. On the SiC chip substrate 1-1, the groove 1-3 prepared by the deep etching process is used to assemble the gold-plated optical fiber 2, and the side in the groove parallel to the reflection end face 2-1 of the gold-plated optical fiber 2 and the closest distance is the chip The internal reflection surface 1-4, the internal reflection surface 1-4 of the chip and the optical fiber reflection end surface 2-1 together form a strain-sensitive EFPI cavity (air EFPI cavity). The size of the grooves 1-3 is slightly larger than the core diameter of the gold-plated optical fiber 2, which can freely move the gold-plated optical fiber 2 in the axial direction while limiting the radial posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com