A tubular NOx sensor

A sensor and tube-type technology, applied in the field of sensors, can solve problems such as small size, complex circuit design, and affecting measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

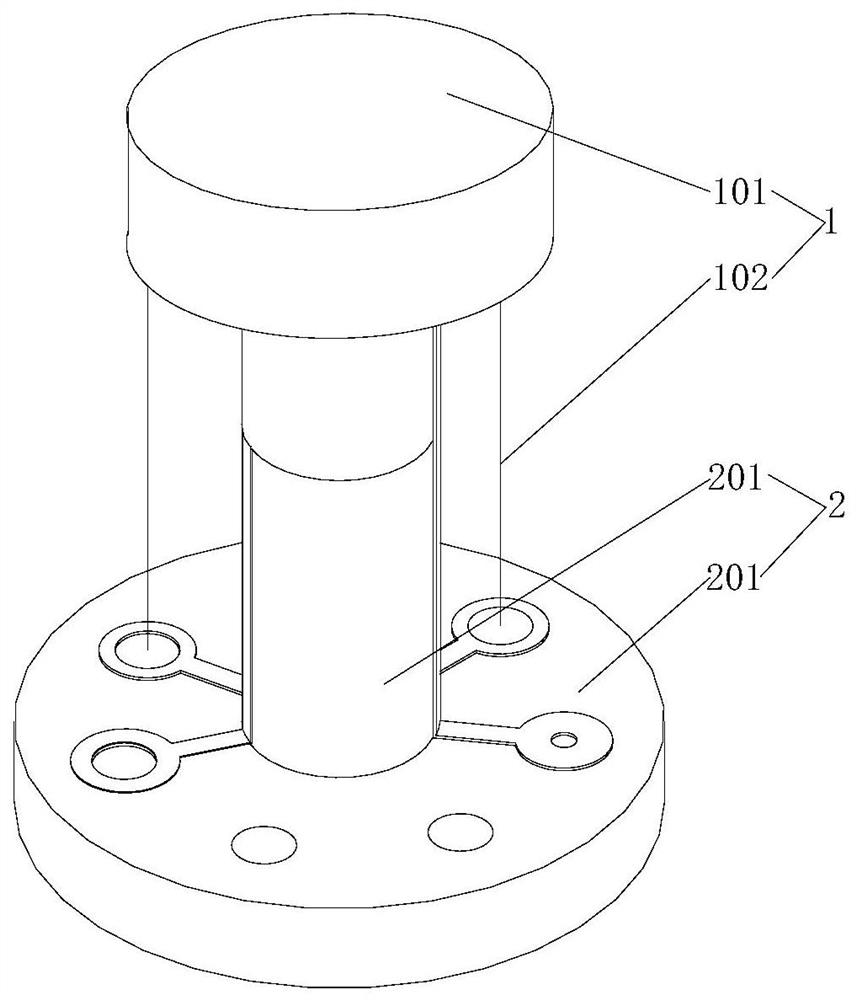

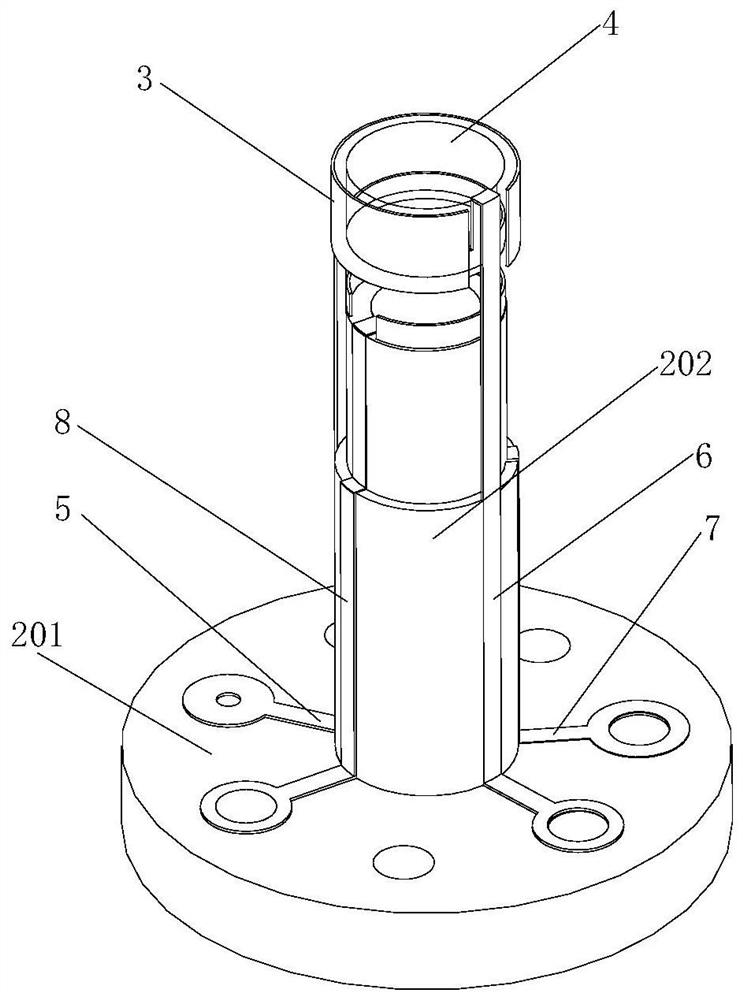

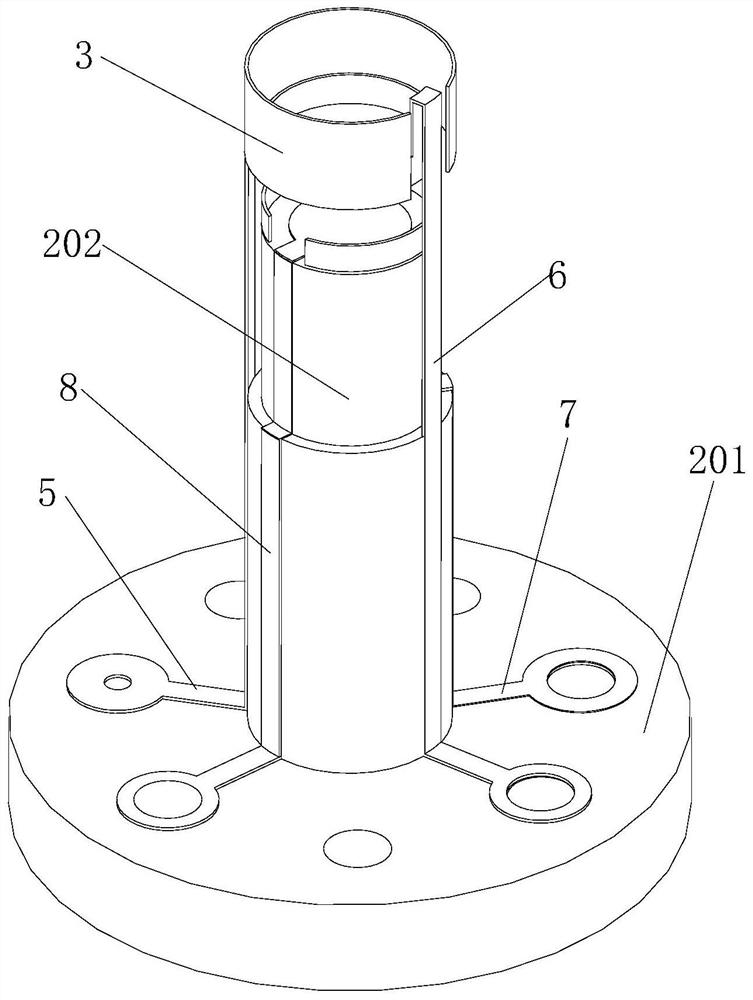

[0019] Please refer to figure 1 and 2 , The embodiment of the present invention provides a tubular NOx sensor, including a heating shell 1 , a base 2 , a diffusion barrier 4 and a sleeve 3 .

[0020] The heating shell 1 is a tubular hollow shell, and the heating shell 1 includes an annular heating sheet 101 and two electrode legs 102, the electrode legs 102 are all vertically arranged, and the lower end edges of the heating sheet 101 are respectively The upper ends of the two electrode legs 102 are fixedly connected, the surfaces of the electrode legs 102 are covered with an insulating layer, and are insulated and connected to the bottom plate through the insulating layer. In this embodiment, the heating sheet 101 is a resistive heating sheet, the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com