Thermal-cracking-resistant cable-used copper alloy conductive material and preparation method thereof

A technology of conductive materials and copper alloys, applied in the direction of conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve the problems of copper alloy thermal processing performance, insufficient thermal cracking resistance, etc. Effects of thermal tearing properties and excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

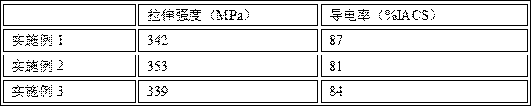

Examples

Embodiment 1

[0050] A copper alloy conductive material for thermal cracking-resistant cables is made of the following raw materials in weight percentage:

[0051] Ni 0.15wt%,

[0052] Cr 0.9wt%,

[0053] Ba 0.3wt%,

[0054] Mo 0.15wt%,

[0055] Ge 0.7wt%,

[0056] Mg 1.0wt%,

[0057] The balance is Cu.

[0058] The preparation method of the above-mentioned copper alloy conductive material for cables comprises the following steps:

[0059] (1) Mix the raw materials according to the stated dosage and then smelt them in a high-temperature smelting furnace. The temperature of the high-temperature smelting furnace is 730°C, keep the temperature constant, and smelt for 0.5h;

[0060] (2) Raise the temperature to 1120°C, keep the temperature fixed, and smelt for 1.5h;

[0061] (3) Lower the temperature of the melting furnace to 710°C and keep it warm for 2 hours;

[0062] (4) After the alloy ingot is prepared, the alloy ingot is rolled into an alloy rod, and then the alloy rod is drawn in...

Embodiment 2

[0064] A copper alloy conductive material for thermal cracking-resistant cables is made of the following raw materials in weight percentage:

[0065] Ni 0.1wt%,

[0066] Cr 1.2wt%,

[0067] Ba 0.1wt%,

[0068] Mo 0.2wt%,

[0069] Ge 0.5wt%,

[0070] Mg 1.3wt%,

[0071] The balance is Cu.

[0072] The preparation method of the above-mentioned copper alloy conductive material for cables comprises the following steps:

[0073] (1) Mix the raw materials according to the stated dosage and then smelt them in a high-temperature smelting furnace. The temperature of the high-temperature smelting furnace is 750°C, keep the temperature constant, and smelt for 1 hour;

[0074] (2) Raise the temperature to 1120°C, keep the temperature fixed, and smelt for 1.5h;

[0075] (3) Lower the temperature of the melting furnace to 730°C and keep it warm for 2 hours;

[0076] (4) After the alloy ingot is prepared, the alloy ingot is rolled into an alloy rod, and then the alloy rod is drawn in...

Embodiment 3

[0078] A copper alloy conductive material for thermal cracking-resistant cables is made of the following raw materials in weight percentage:

[0079] Ni 0.2wt%,

[0080] Cr 0.5wt%,

[0081] Ba 0.5wt%,

[0082] Mo 0.1wt%,

[0083] Ge 0.9wt%,

[0084] Mg 0.7wt%,

[0085] The balance is Cu.

[0086]The preparation method of the above-mentioned copper alloy conductive material for cables comprises the following steps:

[0087] (1) Mix the raw materials according to the stated dosage and then smelt them in a high-temperature smelting furnace. The temperature of the high-temperature smelting furnace is 740°C, keep the temperature constant, and smelt for 0.5h;

[0088] (2) Raise the temperature to 1150°C, keep the temperature fixed, and smelt for 2 hours;

[0089] (3) Lower the temperature of the melting furnace to 750°C and keep it warm for 1 hour;

[0090] (4) After the alloy ingot is prepared, the alloy ingot is rolled into an alloy rod, and then the alloy rod is drawn int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com