SIP packaging method for realizing electromagnetic shielding

A packaging method and electromagnetic shielding technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of increasing the size of the connection between the PCB board and the SIP module, unfavorable miniaturization trends, etc., to save packaging space size, improve flexibility properties, and the effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better illustrate the working mode of the present invention, the present invention will be described in detail with completeness and clarity below in conjunction with specific drawings.

[0015] A SIP encapsulation method for realizing electromagnetic shielding, specifically as follows:

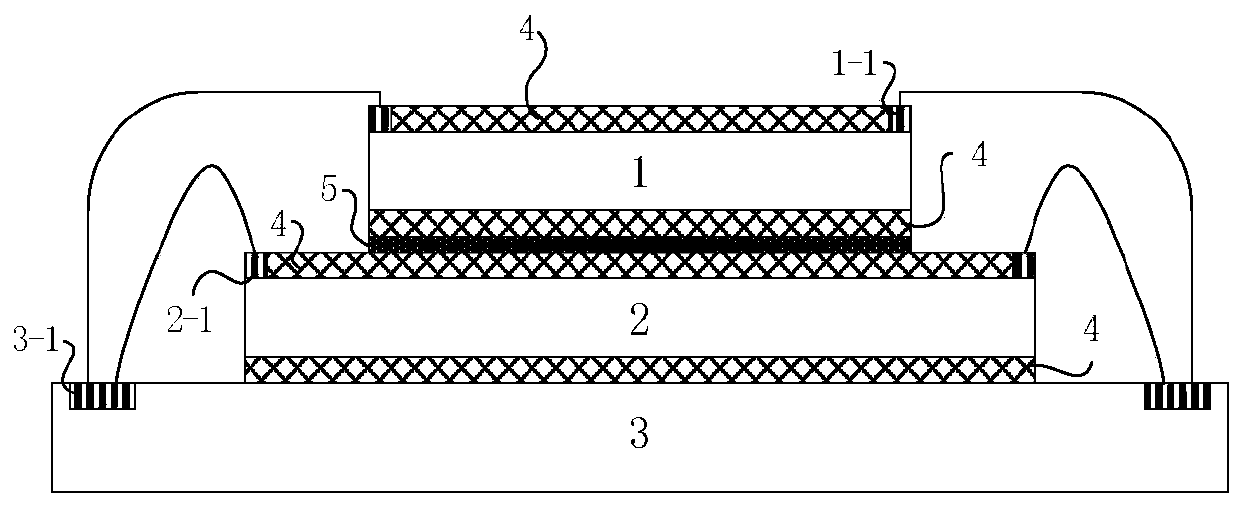

[0016] Such as figure 1 As shown, the hardware of the present invention includes a high-capacity Flash storage chip 1, a MCU chip 2, and a substrate 3 to form a high-storage chip system, which effectively overcomes the insufficient data storage space of the MCU chip.

[0017] Firstly, the upper and lower surfaces of the Flash memory chip 1 and the MCU chip 2 are coated with an absorbing material to form a shielding layer 4 . The edge pins 1-1 of the Flash memory chip 1 and the edge pins 2-1 of the MCU chip 2 are not painted. Shielding layer 4 thickness is 25~100 μ m (the present embodiment adopts 50 μ m), and the absorbing material that adopts is graphene, and graphene is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com