Ionic liquid-containing laminate and method for producing same

一种离子液体、层叠体的技术,应用在含有离子液体的层叠体及其制造领域,能够解决没有离子液体记载等问题,达到控制气体透过性、抑制发粘、操作性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The method for producing such a porous film of thermoplastic resin is not particularly limited, and conventional methods, such as a method using phase separation of a resin solution, a method of stretching a resin film, or irradiating a resin film with high-energy rays such as α-rays, can be used. method etc. to prepare.

[0082] In addition, in order to adjust the wettability (or contact angle) of the liquid (A) containing the ionic liquid, the IL-incompatible porous layer (B) can be subjected to a conventional surface treatment (for example, JP-A-6-9810 The treatment described in , that is, the treatment of attaching a cross-linked body derived from an ethylenically unsaturated monomer having a fluoroalkyl group, etc.).

[0083] Commercially available products can be used as the IL-incompatible porous layer (B), and examples thereof include "C-pore" manufactured by Ube Maxell Co., Ltd., "U-Pore" manufactured by Ube Industries Co., Ltd., and "U-Pore" manufactured by Me...

Embodiment 1

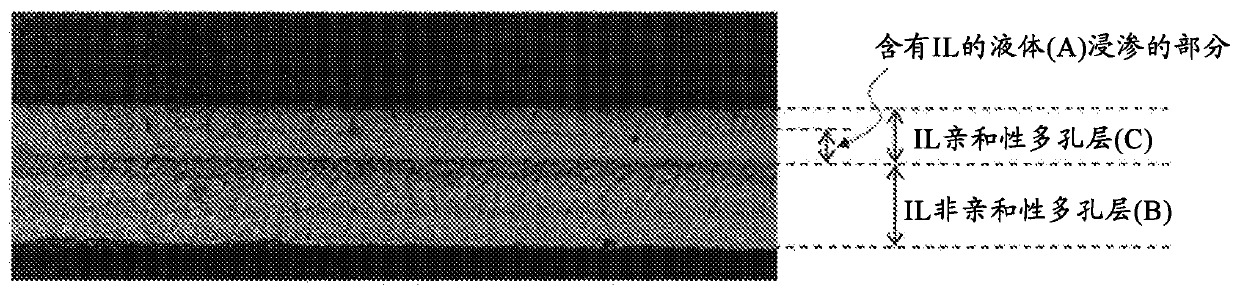

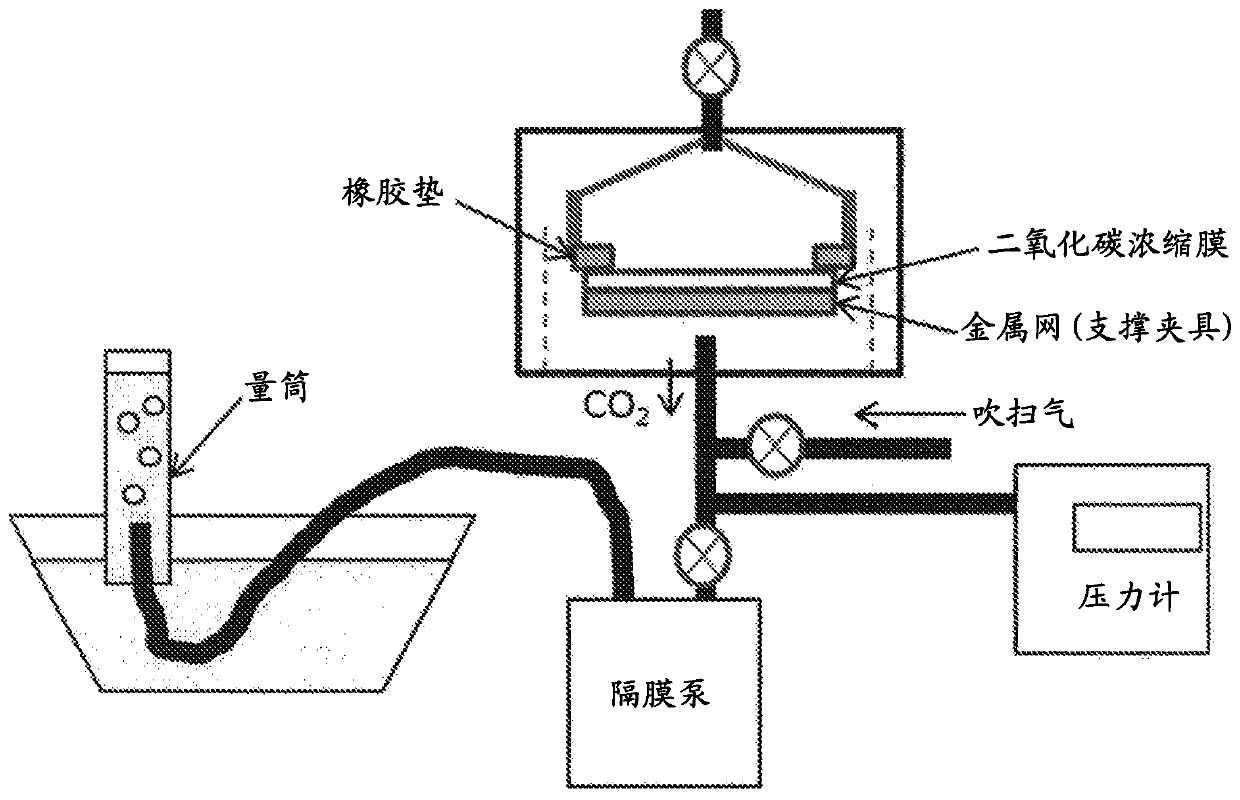

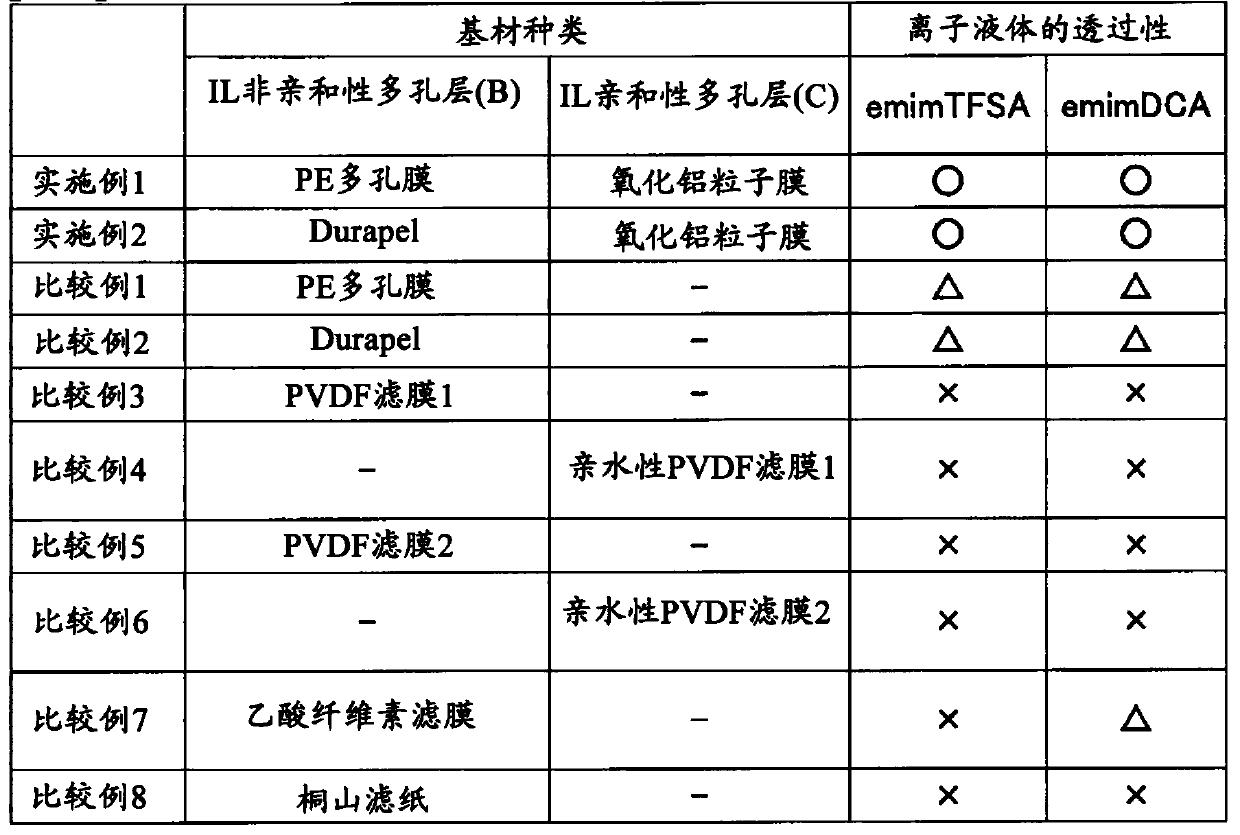

[0148] The above-mentioned alumina particles were mixed with water to prepare an alumina particle dispersion (alumina particle slurry) having a concentration of 8 to 10% by weight. On the PE porous membrane as the IL non-affinity porous layer (B), the obtained alumina particle slurry was coated by wire bar coating, and dried at 100°C for 1 minute to form an IL affinity layer (B). And the porous layer (C). The alumina particle slurry was applied so that the dried IL-affinity porous layer (C) had a thickness of 5 μm. Using the obtained IL-free laminate, the permeability of the ionic liquid was evaluated. It should be noted that the ionic liquid was dripped on the IL-affinity porous layer (C) side of the fixed IL-free laminate, and on the opposite side of the dripped surface (IL-non-affinity porous layer (B) side) was decompressed.

Embodiment 2

[0150] In addition to adding 1% by weight of isopropyl alcohol (IPA) to the aluminum oxide particle dispersion liquid, and using Durapel as the IL non-affinity porous layer (B), the same as the example 1 A laminate not containing IL was prepared in the same manner, and the permeability of the ionic liquid to the obtained laminate not containing IL was evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com