Automatic crushing device for neodymium-iron-boron magnetic powder blocks, and crushing method of automatic crushing device

A pulverizing device and NdFeB technology are applied in the field of automatic pulverizing device, NdFeB magnetic powder block automatic pulverizing device, and NdFeB magnetic powder block automatic pulverizing field, which can solve the problems of low screening efficiency and pulverization efficiency, and achieve improved pulverization. And the effect of screening efficiency and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

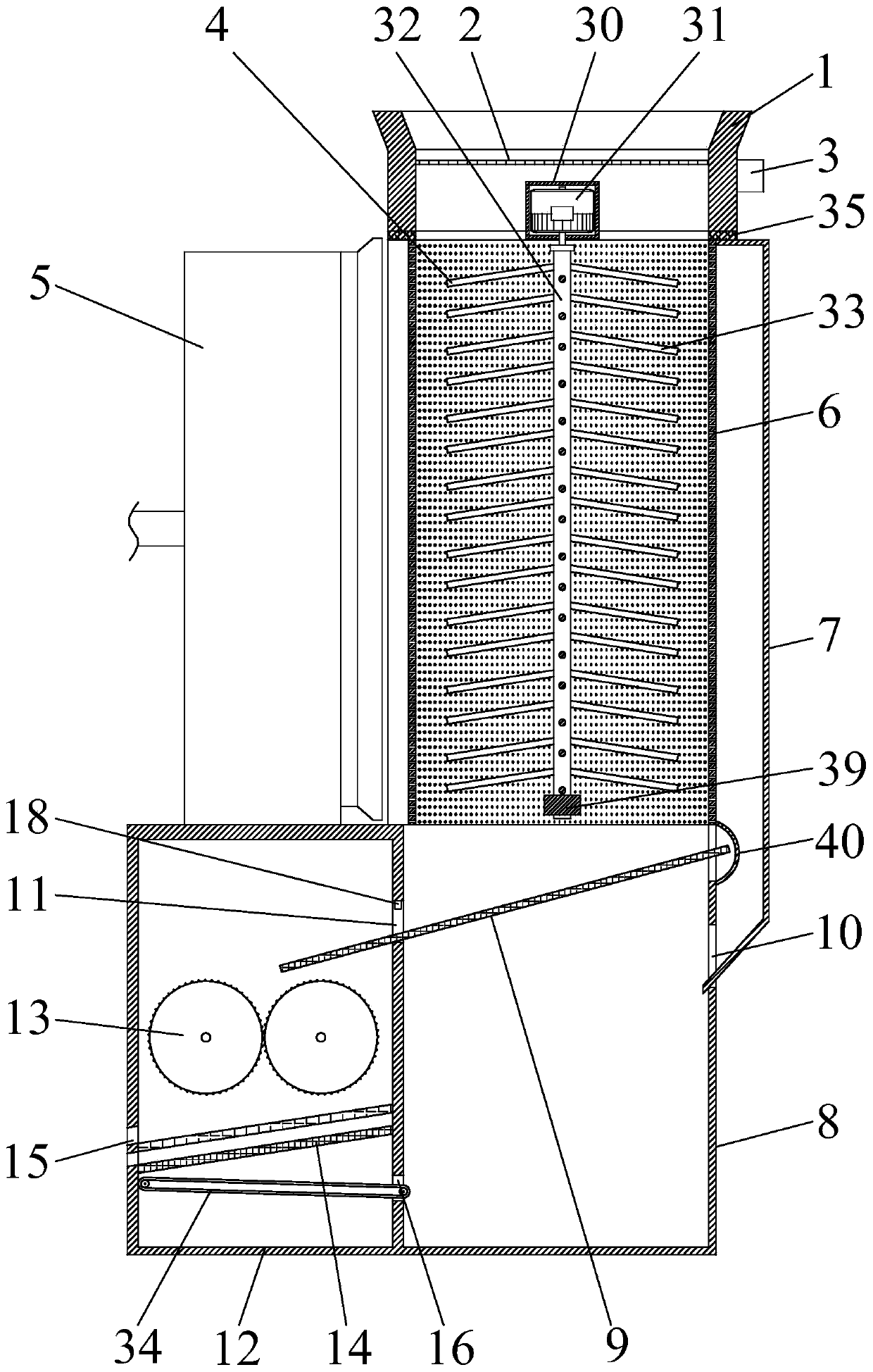

[0074] see figure 1 , The present invention provides an automatic crushing device for NdFeB magnetic powder block, which is used for screening and crushing NdFeB magnetic powder block formed by NdFeB magnetic powder, so as to form magnetic powder in the same particle size range. Wherein, the NdFeB magnetic block automatic crushing device includes a vibration dispersion mechanism, a crushing mechanism, a blast recovery mechanism, a screening and collection mechanism, a crushing mechanism, a detection mechanism and a controller.

[0075] The vibration dispersing mechanism includes a dispersing cylinder 1 , a screen one 2 and a vibration source 3 . The screen one 2 is installed in the dispersing cylinder 1, and is used to screen the NdFeB magnetic powder blocks input from the outside. The vibration source 3 is installed on the dispersion shell 1, and is used to vibrate the screen one 2. In this embodiment, the dispersing cylinder 1 is a cylinder, both ends of which are open end...

Embodiment 2

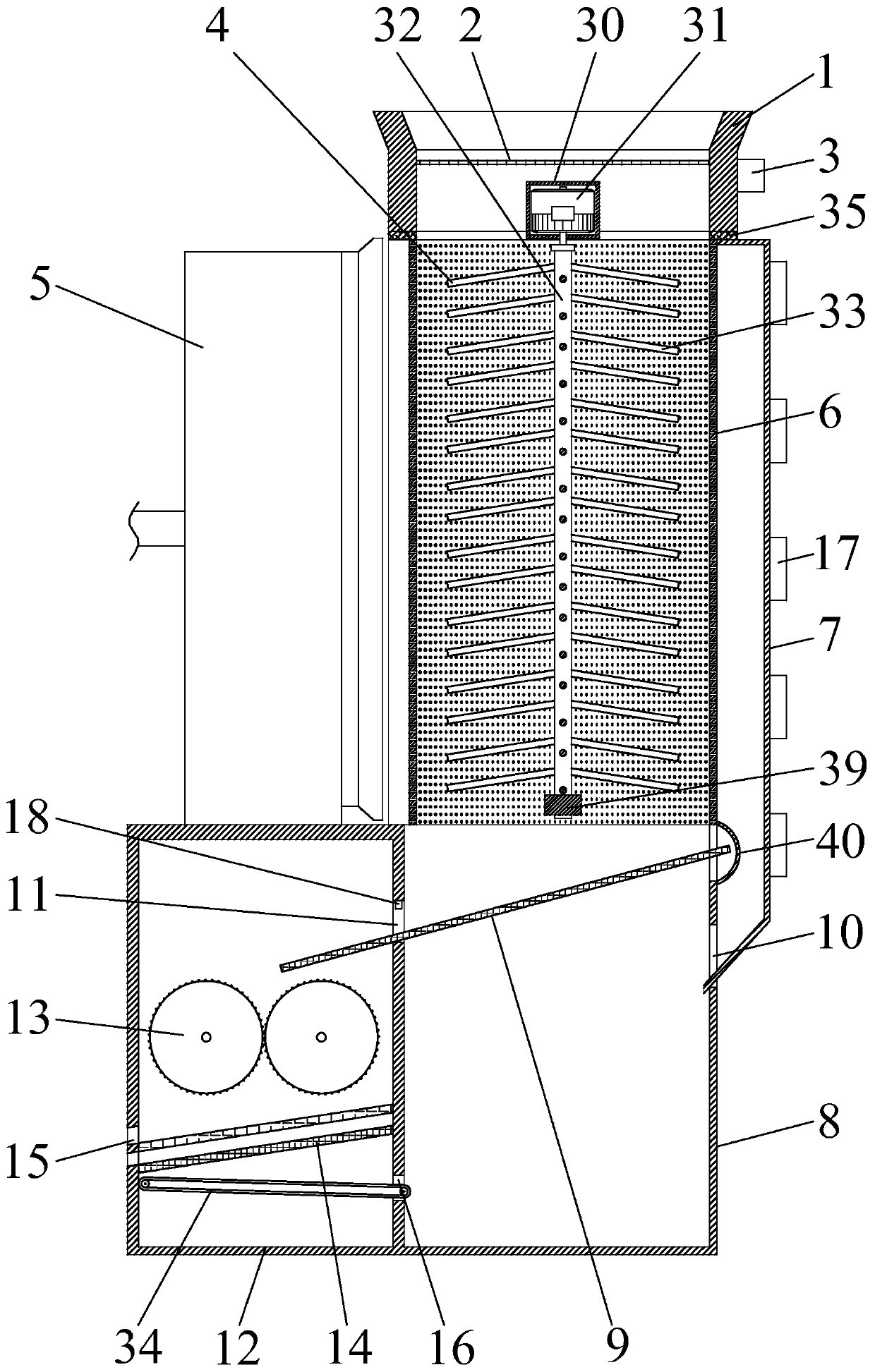

[0087] see figure 2 , this embodiment provides an automatic crushing device for NdFeB magnetic powder blocks, which adds an electromagnet 17 on the basis of Embodiment 1. There are multiple electromagnets 17, and the electromagnets 17 belong to the blowing recovery mechanism. The electromagnet 17 is installed on the outer wall of the recovery housing 7 . The controller is also used to start the electromagnet 17 at intervals of a preset time, so that the magnetism generated by the electromagnet 17 will absorb the magnetic powder of the recovery housing 7 on the inner wall of the recovery housing 7, and during the working time of the electromagnet 17 Close electromagnet 17 when reaching a preset time two.

[0088] Therefore, in the NdFeB magnetic block automatic crushing device provided in this embodiment, the electromagnet 17 of the blower recovery mechanism can generate a magnetic field effect on the magnetic powder in the recovery housing 7, so that the magnetic powder is ...

Embodiment 3

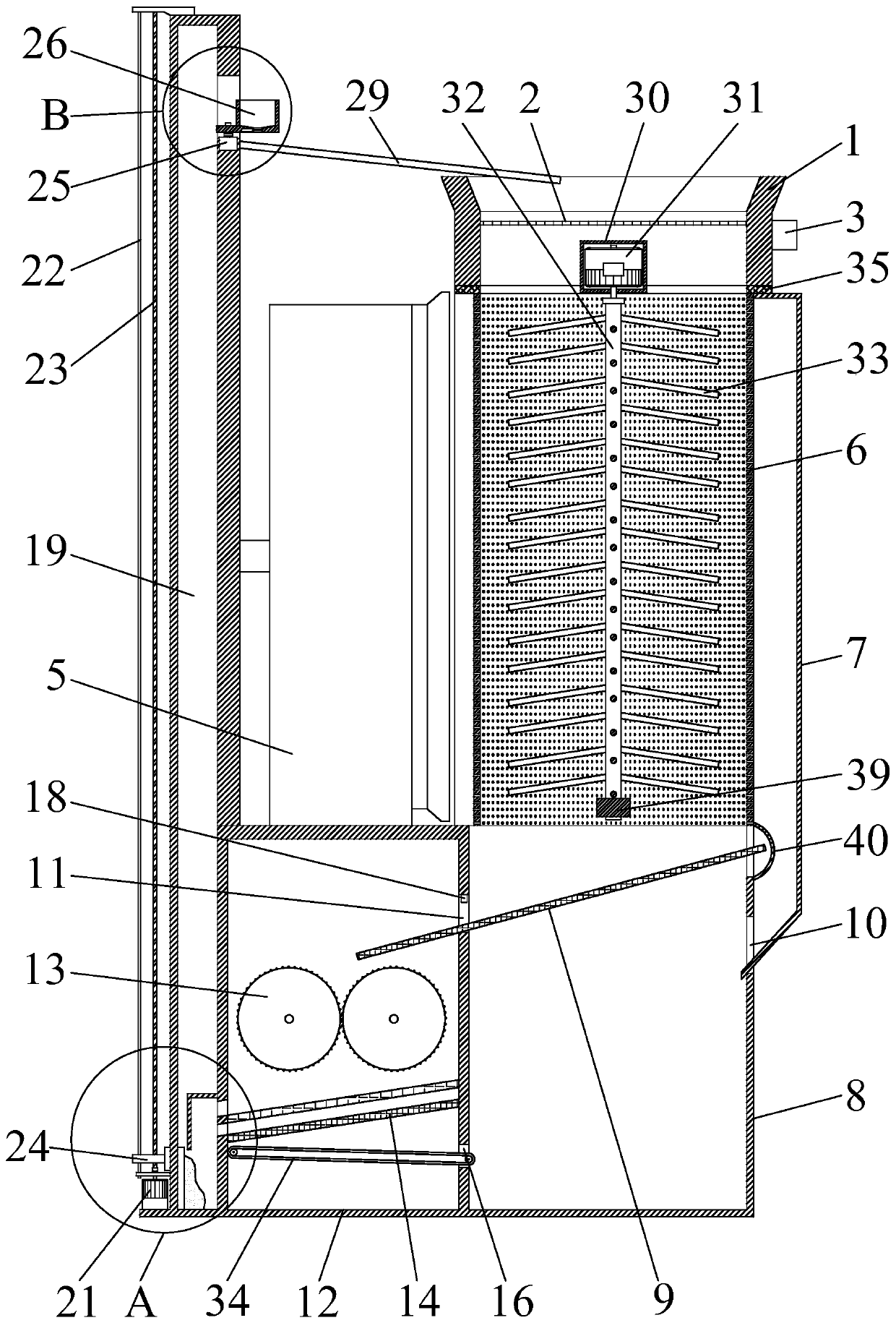

[0090] see Figure 3-7 , This embodiment provides an automatic crushing device for NdFeB magnetic powder blocks, which adds a conveying mechanism on the basis of Embodiment 1. The conveying mechanism is used to convey the NdFeB magnetic powder blocks rolled out from the outlet one 15 to the screen one 2 . Among them, the controller drives the conveying mechanism to convey the NdFeB magnetic powder blocks once every three preset times.

[0091] The conveying mechanism in this embodiment includes a lifting bucket 19, a lifting component, an electromagnetic adsorption block 20, a material transfer component and a material feeding component. The lifting bucket 19 is located on one side of the crushing shell 12, and receives the NdFeB magnetic powder blocks rolled out from the outlet one 15. A discharge port 36 is provided on the side wall of the lifting barrel 19, and the height of the discharge port 36 is higher than that of the dispersion cylinder 1 . The lifting assembly is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com