Preparing equipment of ultraviolet high-resistance fluorine-containing plastic particles

A plastic particle and high-barrier technology, which is applied in the field of preparation equipment for ultraviolet high-barrier fluorine-containing plastic particles, can solve the problems of unfavorable manual handling by workers, shrinkage of particle volume, and inability to uniformly control the pressure of raw materials, etc., to improve the production efficiency. Speed and quality, avoid sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

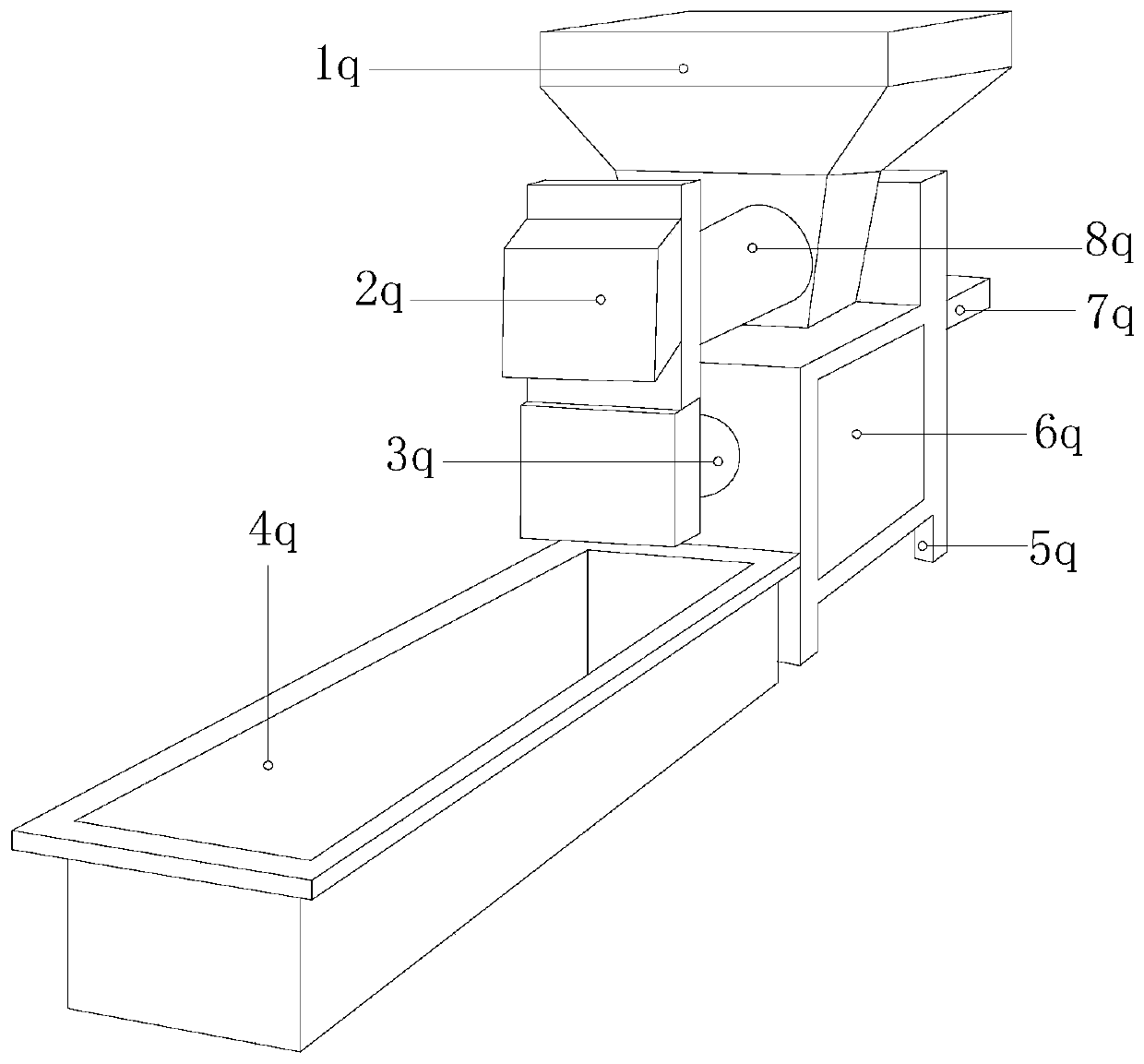

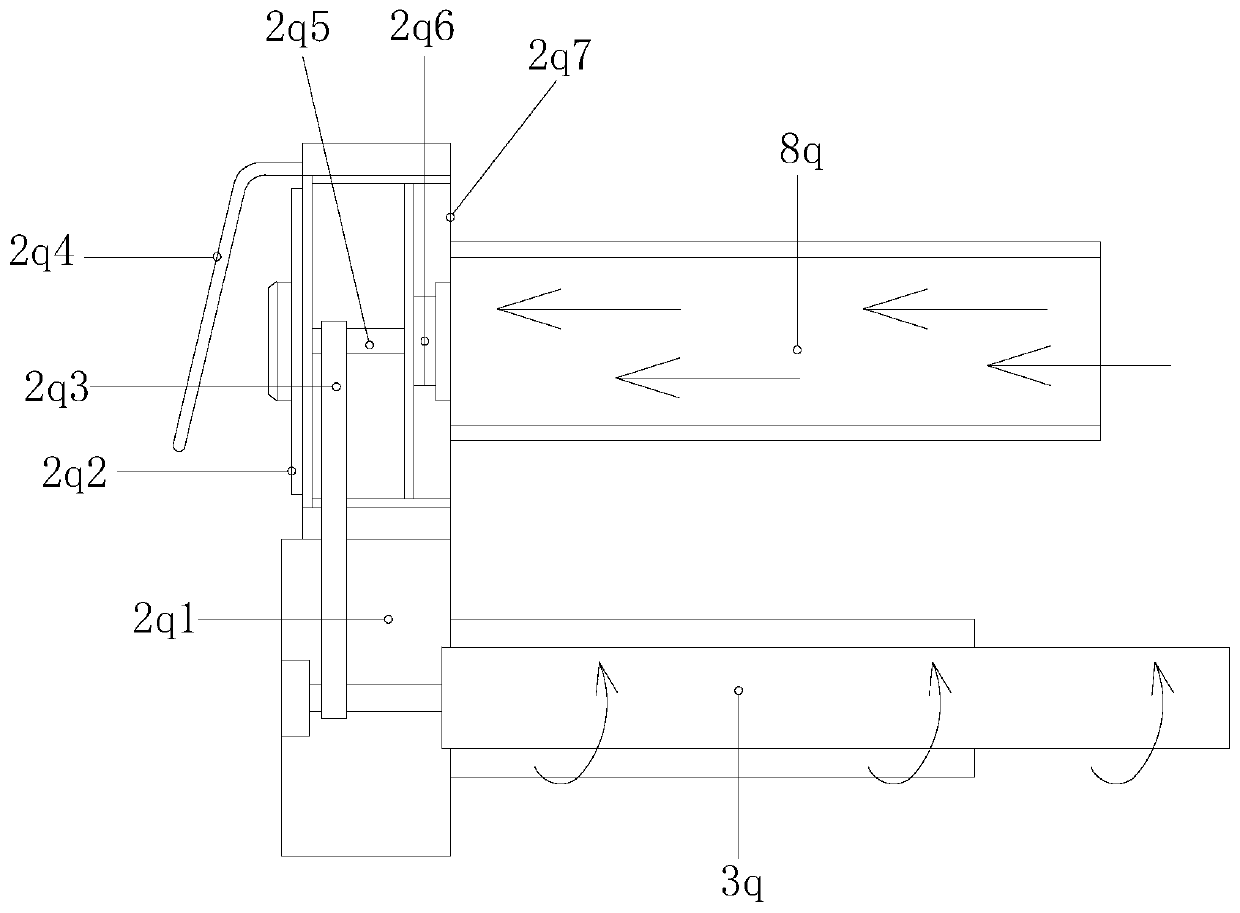

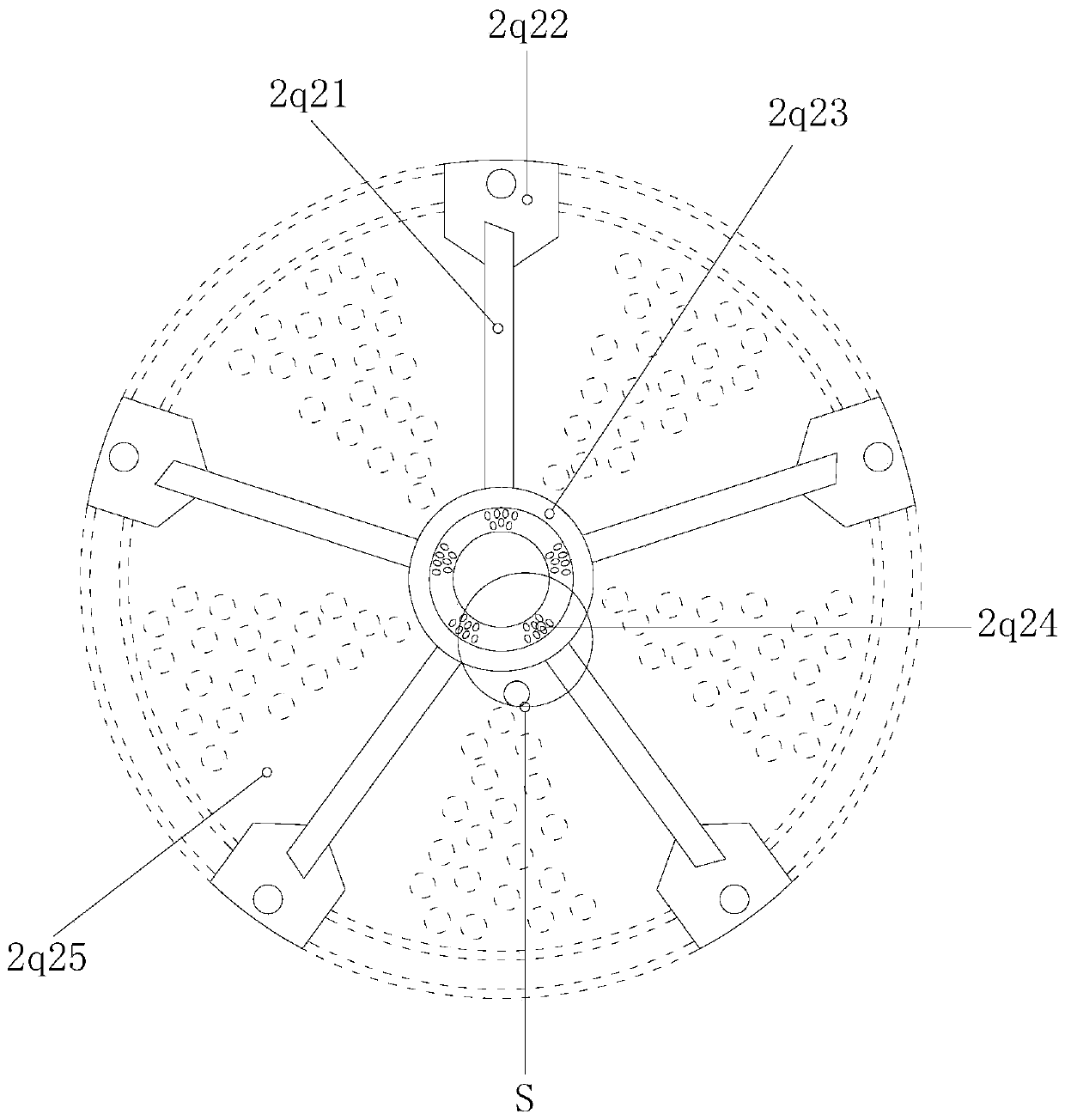

[0028] see Figure 1-Figure 6 , the present invention provides a kind of preparation equipment of fluorine-containing plastic particles with high ultraviolet barrier, its structure includes hopper 1q, granulation assembly 2q, drive shaft 3q, placement box 4q, fixed foot 5q, preparation host 6q, motor tray 7q, hot-melt The pipe 8q, the bottom of the hopper 1q is installed on the top of the preparation host 6q by fastening, the four corners of the bottom of the preparation host 6q are respectively provided with fixed feet 5q, and the rear end of the transmission shaft 3q is installed inside the preparation host 6q. The rear end of the preparation host 6q is provided with a motor tray 7q, and the rear end of the hot-melt pipe 8q is installed on the lower end of the hopper 1q by embedding. The front end of 3q is fastened to the lower end of the granulation assembly 2q, the preparation host 6q is connected to the hot-melt pipe 8q, the rear end of the placement box 4q is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com