Foam-filled three-period minimum-curved-surface porous structure sandwich panel and preparation method thereof

A technology of extremely small curved surface and porous structure, applied in chemical instruments and methods, lamination, layered products, etc., to achieve the effects of improving mechanical properties, overcoming uneven force transmission, and overcoming stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

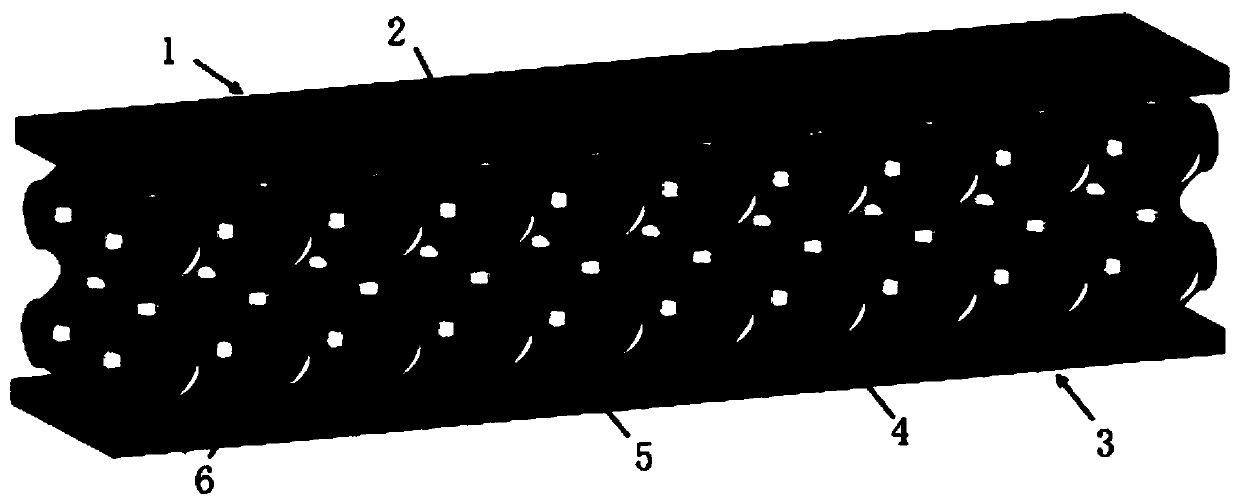

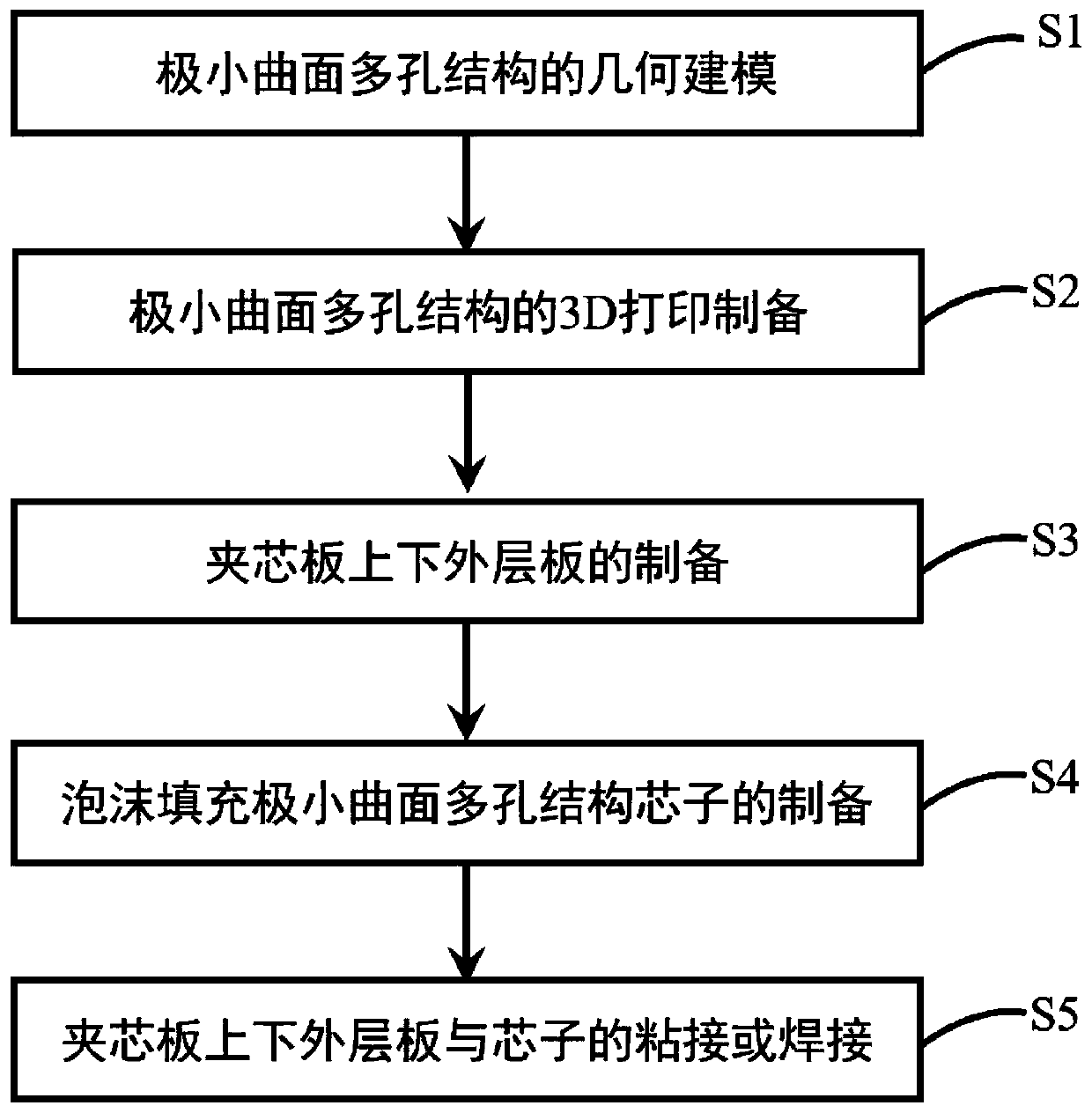

[0063] Another aspect of the present invention provides a method for preparing a foam-filled sandwich panel with a three-dimensional periodic minimally curved surface porous structure. First, the 3D printing technology is integrated to prepare an upper inner layer sheet 2, a lower inner layer sheet 4, and four sides. A transparent three-period minimally curved porous structure 5; then place the 3D printed structure in a container containing a foaming agent, and foam it through rapid foaming technology, so that the foam material 6 is fully filled into the minimally curved porous structure In step 5, after the foam is fully shaped, the excess foam on the four sides of the porous structure is removed to form a foam-filled three-dimensional periodic minimal curved surface porous structure core; for the P-shaped surface, the excess foam outside the cells of the porous structure can be further removed, and finally through By laser welding or gluing, the upper outer solid plate 1 and ...

Embodiment 1

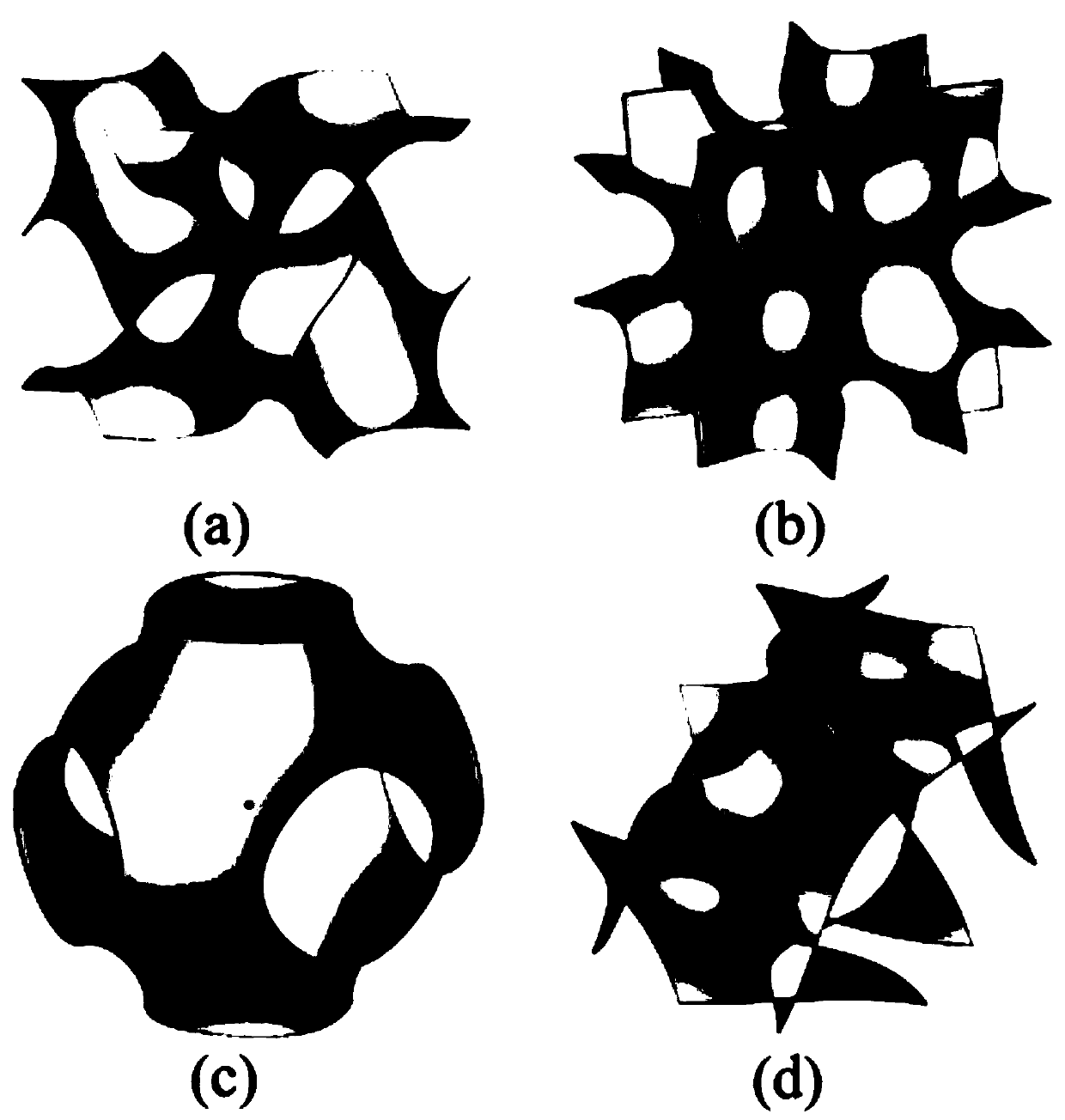

[0071] Based on the mathematical expression of the G-type minimal curved surface in the present invention, use MATLAB software to generate a cube G-shaped minimal curved surface porous structure point cloud model with a cell side length of 10mm, and then build a total length of 180mm by means of the three-dimensional modeling software Solidworks. The three-dimensional geometric model of the G-shaped minimally curved porous structure 5 with a total width of 40 mm, a total height of 20 mm, and a curved surface wall thickness of 1.5 mm, and then establish an upper inner layer sheet 2 and a lower inner layer sheet 4 with a length of 180 mm, a width of 40 mm, and a height of 2 mm And consolidate with the established G-type minimally curved porous structure 5 three-dimensional geometric model to form a minimally curved porous structure three-dimensional model including upper and lower inner layer thin plates;

[0072] Convert the established geometric model including the extremely sm...

Embodiment 2

[0077] Based on the mathematical expression of the P-type minimal curved surface in the present invention, use MATLAB software to generate a cube P-type minimal curved surface porous structure point cloud model with a cell side length of 10mm, and then construct a total length of 180mm, The three-dimensional geometric model of the P-type minimally curved porous structure 5 with a total width of 40 mm, a total height of 20 mm, and a curved surface wall thickness of 1.5 mm, and then establish an upper inner layer sheet 2 and a lower inner layer sheet 4 with a length of 180 mm, a width of 40 mm, and a height of 2 mm And consolidated with the established P-type minimally curved porous structure 5 three-dimensional geometric model to form a minimally curved porous structure three-dimensional model including upper and lower inner thin plates;

[0078] Convert the established geometric model including the extremely small curved surface porous structure 5, the upper inner layer sheet 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com