Preparation method of plasterboard and plasterboard

A paper-faced gypsum board and gypsum board technology, applied in the field of building materials, can solve problems such as untimely treatment, incomplete treatment, and long cleaning time, and achieve the effects of reducing impact, shortening final setting time, and reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Optionally, the preparation method of the gypsum board slurry comprises:

[0028] Mix desulfurized gypsum clinker, modified starch, coagulant and functional additives, and stir to make a uniform mixed powder;

[0029] Mix foaming agent, compressed air and water, and stir to make foaming liquid;

[0030] The above mixed powder, foaming liquid and water are mixed and stirred to prepare the gypsum board slurry.

[0031] Optionally, the final setting time of the gypsum board slurry is 180s-220s.

[0032] Optionally, the desulfurized gypsum clinker, modified starch, coagulant and functional additives are stirred by a circular roller reamer to make a mixed powder.

[0033] Optionally, the coagulant is raw gypsum.

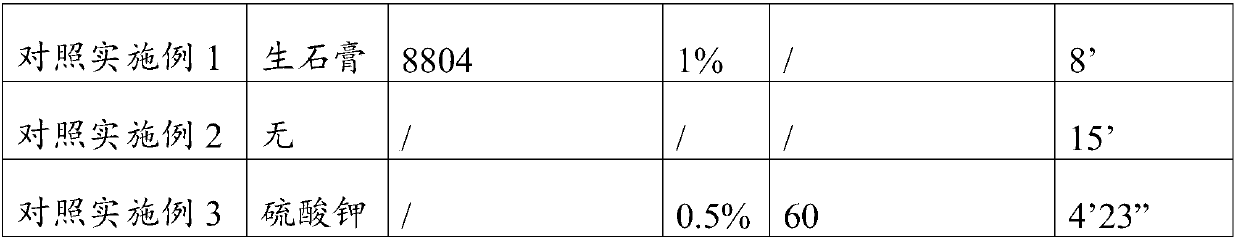

[0034] Compared with the prior art, the present invention adds raw gypsum coagulant according to the production situation, so that the final setting time of the gypsum board is 180s to 220s, so that the gypsum board can achieve complete final setting at the cutt...

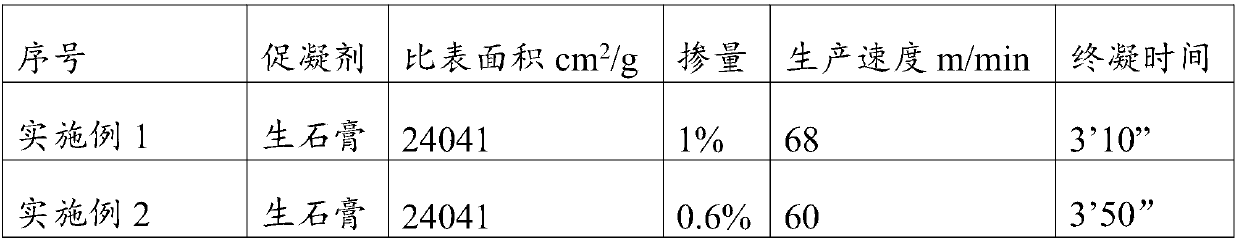

Embodiment 1

[0042] A paper-faced gypsum board, said paper-faced gypsum board is made of the following components in parts by weight: 100 parts by weight of desulfurized gypsum clinker, 75 parts by weight of water, wherein 5 parts by weight of water is mixed with a foaming agent, and raw gypsum 1 part by weight, 1 part by weight of foaming agent, 0.8 part by weight of starch and 0.5 part by weight of water reducer, the specific surface area of the raw gypsum is 24041cm 2 / g.

[0043] The preparation method of above-mentioned gypsum board comprises the steps:

[0044] Step 1. Mix 100 parts by weight of desulfurized gypsum clinker, 0.8 parts by weight of modified starch, 1 part by weight of raw gypsum and 0.5 parts by weight of functional additives, and stir to form a uniform mixed powder;

[0045] Step 2, mixing 1 part by weight of foaming agent, 5 parts by weight of water and compressed air, and stirring to make foaming liquid;

[0046] Step 3, mix the above-mentioned mixed powder, foa...

Embodiment 2

[0049]A paper-faced gypsum board, said paper-faced gypsum board is made of the following components in parts by weight: 80 parts by weight of desulfurized gypsum clinker, 62 parts by weight of water, wherein 4 parts by weight of water is mixed with a foaming agent, and raw gypsum 0.5 parts by weight, 1 part by weight of foaming agent, 0.5 parts by weight of starch and 0.5 parts by weight of water reducing agent, the specific surface area of the raw gypsum is 24041cm 2 / g.

[0050] The preparation method of above-mentioned gypsum board comprises the steps:

[0051] Step 1. Mix 80 parts by weight of desulfurized gypsum clinker, 0.5 parts by weight of modified starch, 0.5 parts by weight of raw gypsum and 0.5 parts by weight of functional additives, and stir to form a uniform mixed powder;

[0052] Step 2, mixing 1 part by weight of foaming agent, 4 parts by weight of water, and compressed air with water, and stirring to make a foaming liquid;

[0053] Step 3, mix the above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com