±1100kv UHV DC transmission line 200kn level hard insulation rod

A technology for UHV DC and transmission lines, applied in the direction of overhead lines/cable equipment, etc., which can solve the problems of weak anti-aging and anti-ultraviolet performance, no substantial improvement, unsuitable for high-altitude operations, etc., to achieve super weather resistance and Chemical medium corrosion resistance, high tension, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

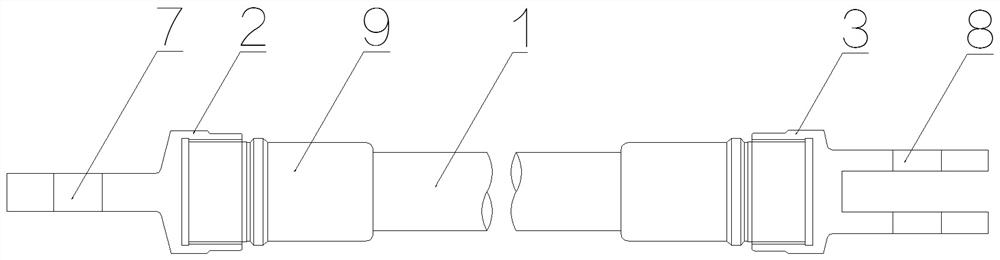

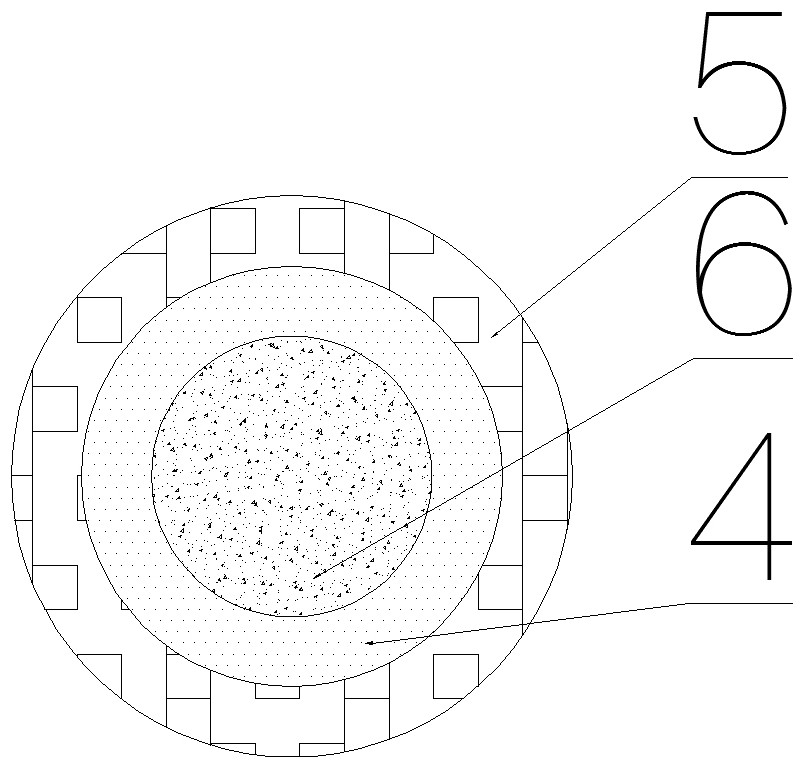

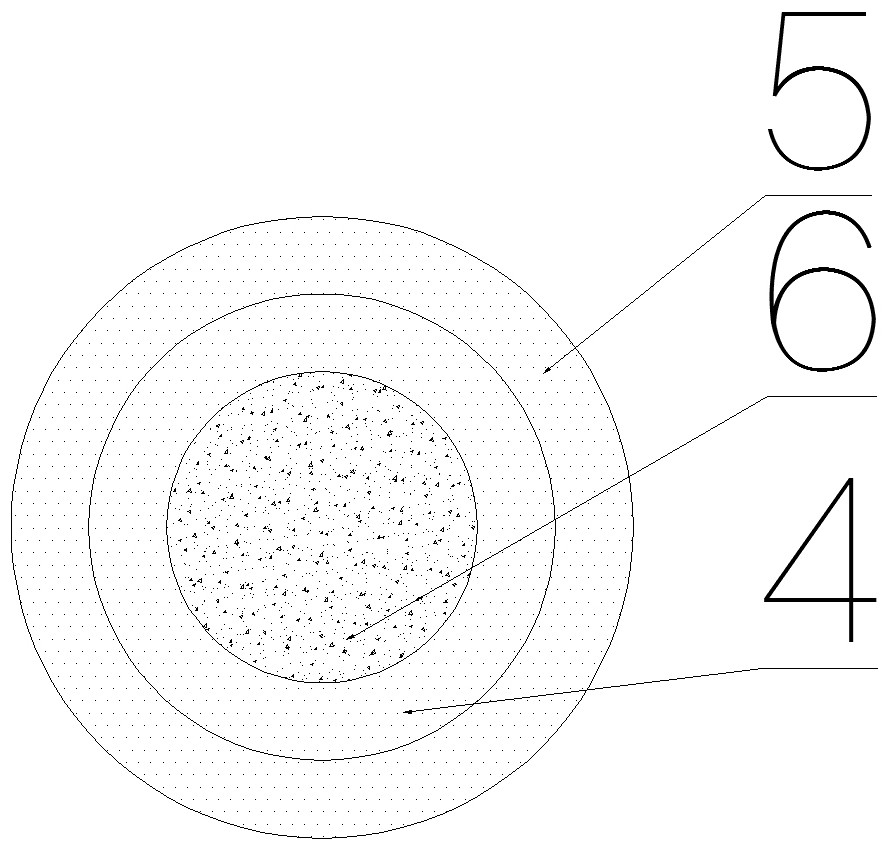

[0050] Such as Figure 1-2As shown, a ±1100kV UHV DC transmission line 200kN grade rigid insulated pull rod, including a rod body 1, a connector 2 and a connector 2 3, the rod body 1 is made by a new process, including a body 4, a sheath 5 and foam core 6, the body 4 is a hollow tube made of epoxy resin and insulating fiber, filled with foam core 6, the foam core 6 is made of closed-cell plastic foam, and the mechanical strength of closed-cell foam plastic is relatively high, Excellent heat insulation and cushioning properties, low water absorption and high insulation performance. A sheath 5 is provided outside the body 4 , and the sheath 5 is in close contact with the body 4 , and the sheath 5 plays a protective role for the body 4 .

[0051] The two ends of the rod body 1 are threadedly connected with the connector one 2 and the connector two 3 respectively, one end of the connector one 2 is provided with a threaded joint and the other end is provided with a single-ear bolt...

Embodiment 2

[0075] Such as image 3 As shown, the structures of this embodiment and the first embodiment are basically the same, the difference is that: the insulating fiber A is a PBO fiber, and the insulating fiber B is a PBO fiber. In this embodiment, the diameter of the foam core is 20mm, the diameter of the body is 30mm, the diameter of the sheath is 40mm, and the breaking force is 821kN, meeting the requirements of 200kN level hard insulating rods for ±1100kV UHVDC transmission lines.

Embodiment 4

[0080] This embodiment is basically the same as Embodiment 1, the difference being that: the outside of the rod body 1 is provided with an anti-ultraviolet coating, the anti-ultraviolet coating is a fluorine-containing polyurethane coating, which has super weather resistance and chemical medium corrosion resistance, and is stable under ultraviolet irradiation. Good sex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com