Flexible graphene electric heating net and preparation method thereof

A technology of flexible graphite and electric heating network, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of not being able to fully fit the surface of the human body, affecting wearing comfort, and poor light transmission, achieving low cost, The effect of reducing radiation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] (1) The graphene electric heating layer has 6 to 10 layers of graphene, with a carbon content > 85%, less graphene consumption, low cost, and good flexibility of the graphene electric heating network, which can fit complex surfaces.

[0025] (2) The graphene electric heating layer and the protective insulating layer are made of the same polymer material, so that the interface between the graphene electric heating layer and the protective insulating layer has a strong binding ability and is not easy to fall off. In practical applications, the polymer material is one of epoxy resin, polyurethane resin and acrylic resin.

[0026] (3) The dispersant is at least one of polyvinylpyrrolidone (PVP), sodium dodecylbenzenesulfonate (SDBS), sodium carboxymethylcellulose (CMC), and sodium dodecyl sulfate (SDS). kind.

[0027] (4) The curing agent is at least one of dicumyl peroxide (DCP), hexamethylene diisocyanate (HDI), p-phenylene diisocyanate (PPDI), biuret polyisocyanate (HDI...

Embodiment 1

[0037] A kind of flexible graphene electric heating net, its preparation method can comprise the following steps:

[0038] Step 1. In parts by mass, mix 100 parts of polyurethane water-based resin, 2.05 parts of graphene, 0.6 part of dispersant CMC, 22.5 parts of deionized water, and 1.05 parts of curing agent HDI to prepare graphene electric heating layer slurry ; In parts by mass, 100 parts of polyurethane water-based resin, 1.05 parts of curing agent HDI, and 22.5 parts of deionized water are mixed together to obtain a protective insulating layer slurry;

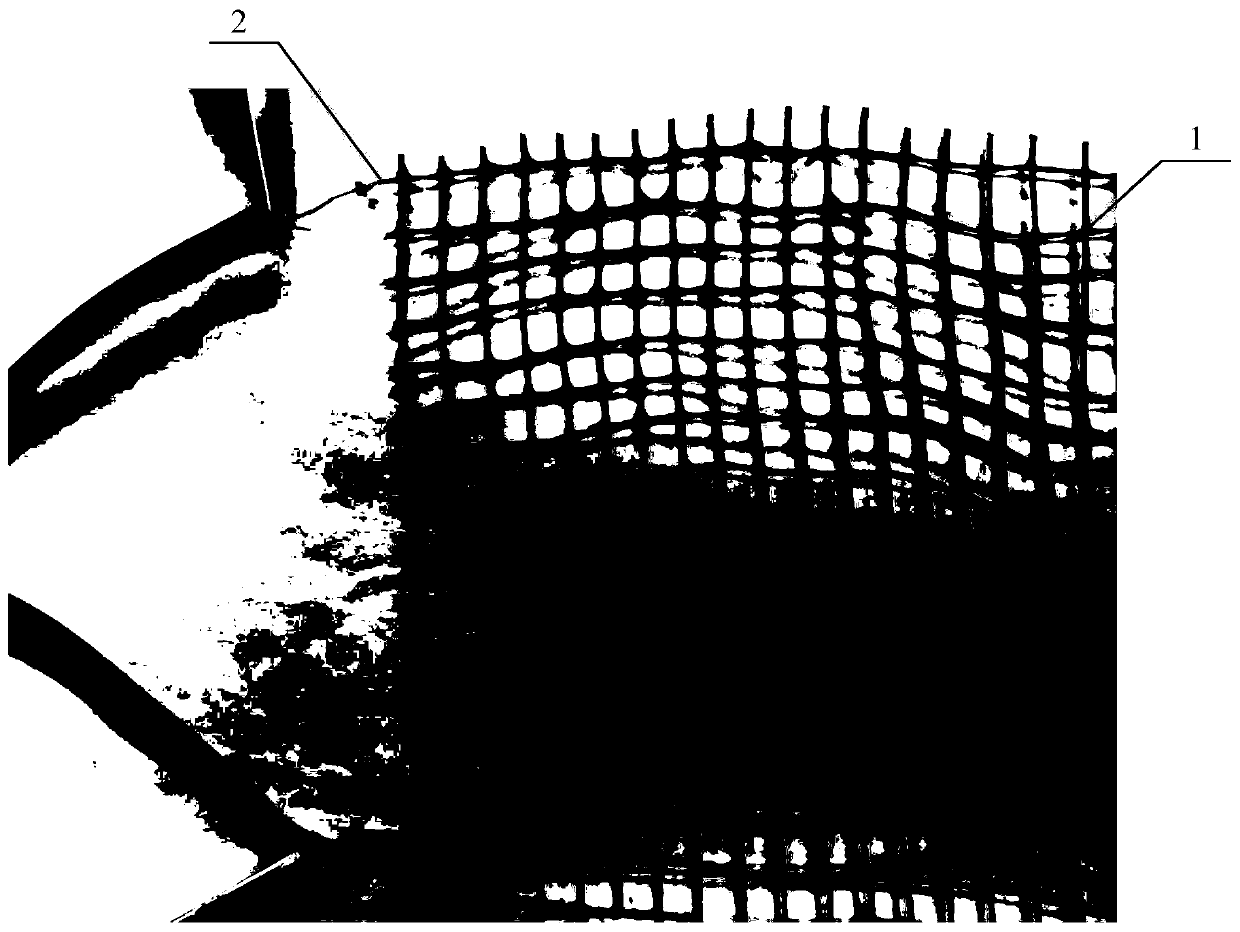

[0039] Step 2. Bond the graphene electric heating layer slurry with the radiation-proof mesh material made of glass fiber with a mesh size of 5 mm × 5 mm by hot pressing and drying, and then bond with the protective insulating layer slurry Integrate and dry to make a flexible graphene electric heating network.

[0040] Wherein, the radiation-proof mesh material is built with metal wires parallel to the warp wires at a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com