Supersolid three-dimensional watering powder and preparation method thereof

A super three-dimensional, three-dimensional technology, which is applied in the field of super three-dimensional three-dimensional pouring powder and its preparation, can solve the problems of limited molding effect, single three-dimensional structure of the product, and difficulty in three-dimensional shaping, so as to achieve diversified powder shapes and good user experience , the effect of improving the sense of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

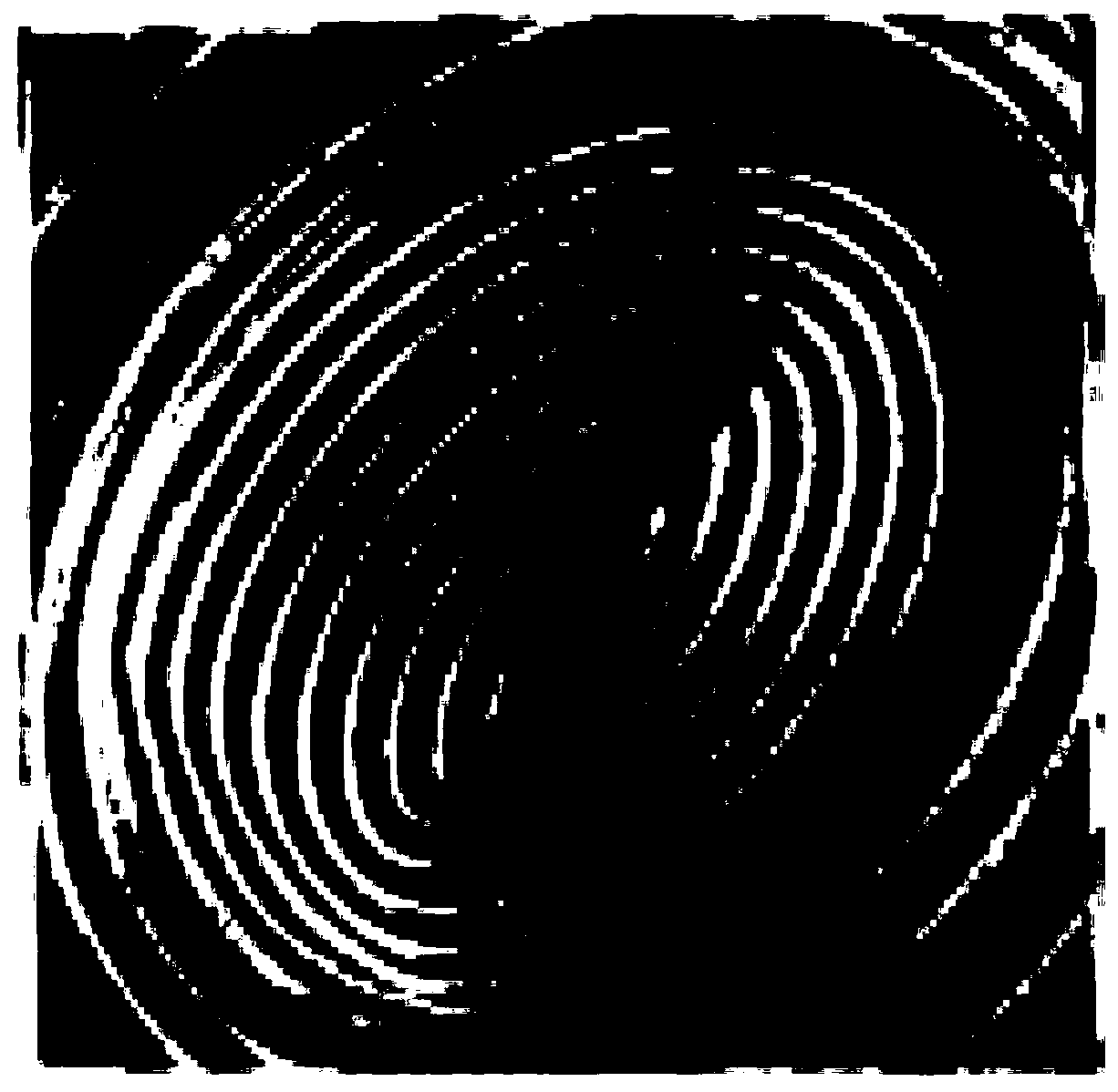

Image

Examples

preparation example Construction

[0033] A kind of preparation method of super three-dimensional watering powder of the present invention, comprises the following steps:

[0034] S1: Add the skin feeling regulator and the toner into the No. 1 container, mix and stir at room temperature until the color development is uniform, and a mixture A is obtained;

[0035] S2: adding the oil compound, thickener, film-forming agent, humectant, and chelating agent into the No. 2 container, and heating and stirring it to obtain an emulsion-like mixture B;

[0036] S3: Slowly add the mixture A to the No. 2 container, and mix it with the mixture B evenly at a temperature of 60-80°C;

[0037] S4: under agitation, the pH regulator and the volatile solvent are added to the No. 2 container, and the mixture is evenly mixed to a flowable fluid;

[0038] S5: After cooling down to 30-60°C, add preservatives, antioxidants, flavors, and fully stir to obtain mixture C;

[0039] S6: the mixture C is put into a vacuum container for defoam...

Embodiment 1

[0042] Each component is weighed by the following mass percentage, and the specific proportioning of each component is shown in Table 1:

[0043] Table 1

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com