Luggage tray horizontal distributing device

A technology of diverting device and tray, applied in the directions of transportation and packaging, conveyor, roller table, etc., can solve the problems of inability to control the synchronous deflection of deflection wheels and high equipment cost, and achieve flexible and ingenious structural design and low equipment use cost. , to ensure the effect of transmission reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

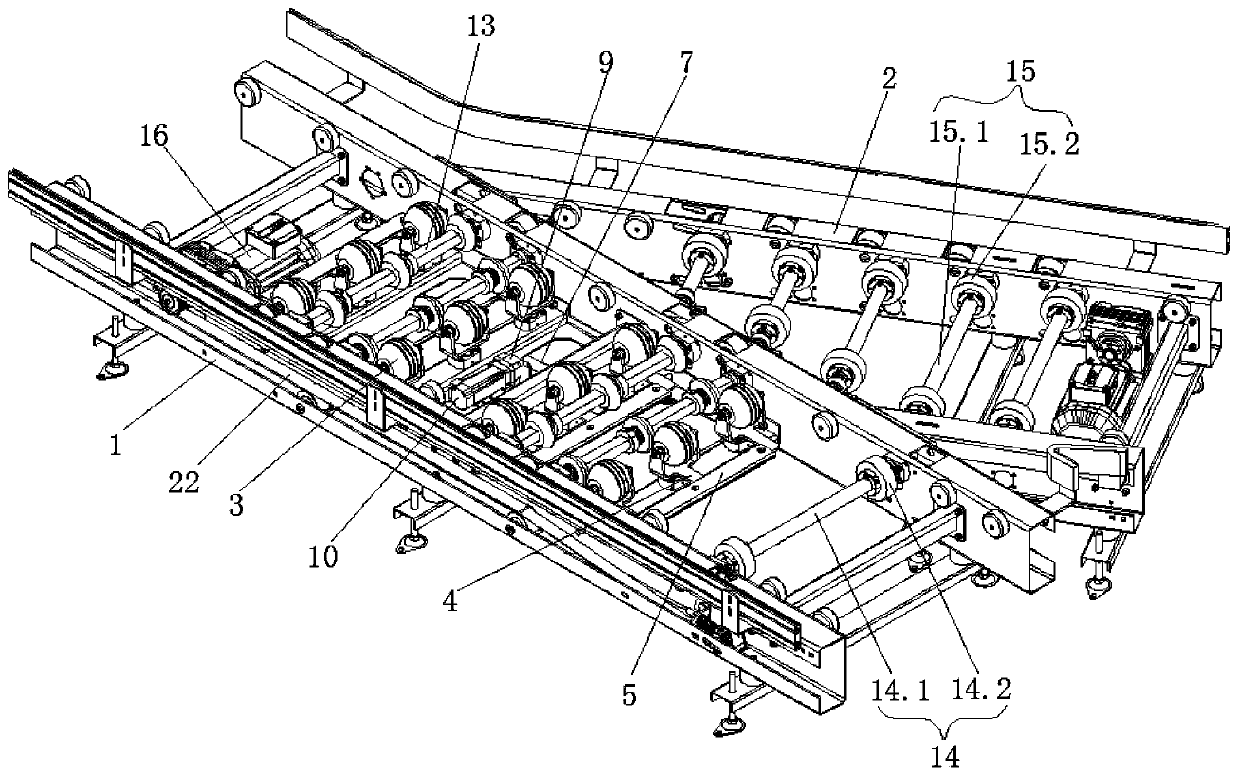

[0041] Such as Figures 1 to 10 As shown, this embodiment provides a luggage pallet horizontal distribution device, including a main line rack 1, a branch line rack 2 is connected to the side end of the main line rack 1, and a distribution unit is arranged on the main line rack 1 near the branch line rack 2 , the splitter unit includes several deflection mechanisms 3 arranged vertically and horizontally. The deflection mechanisms 3 are rotatably connected to the main line frame 1. The side ends of the deflection mechanisms 3 are connected with crank connecting rods A4 parallel to the length direction of the main line frame 1. The same horizontal The deflection mechanisms 3 in the row are all connected with the transverse link 5 through the crank connecting rod A4, the transverse link 5 is perpendicular to the length direction of the main line frame 1, and the bottom of the deflection mechanism 3 in the middle row is connected with a The crank connecting rod B6 and the crank co...

Embodiment 2

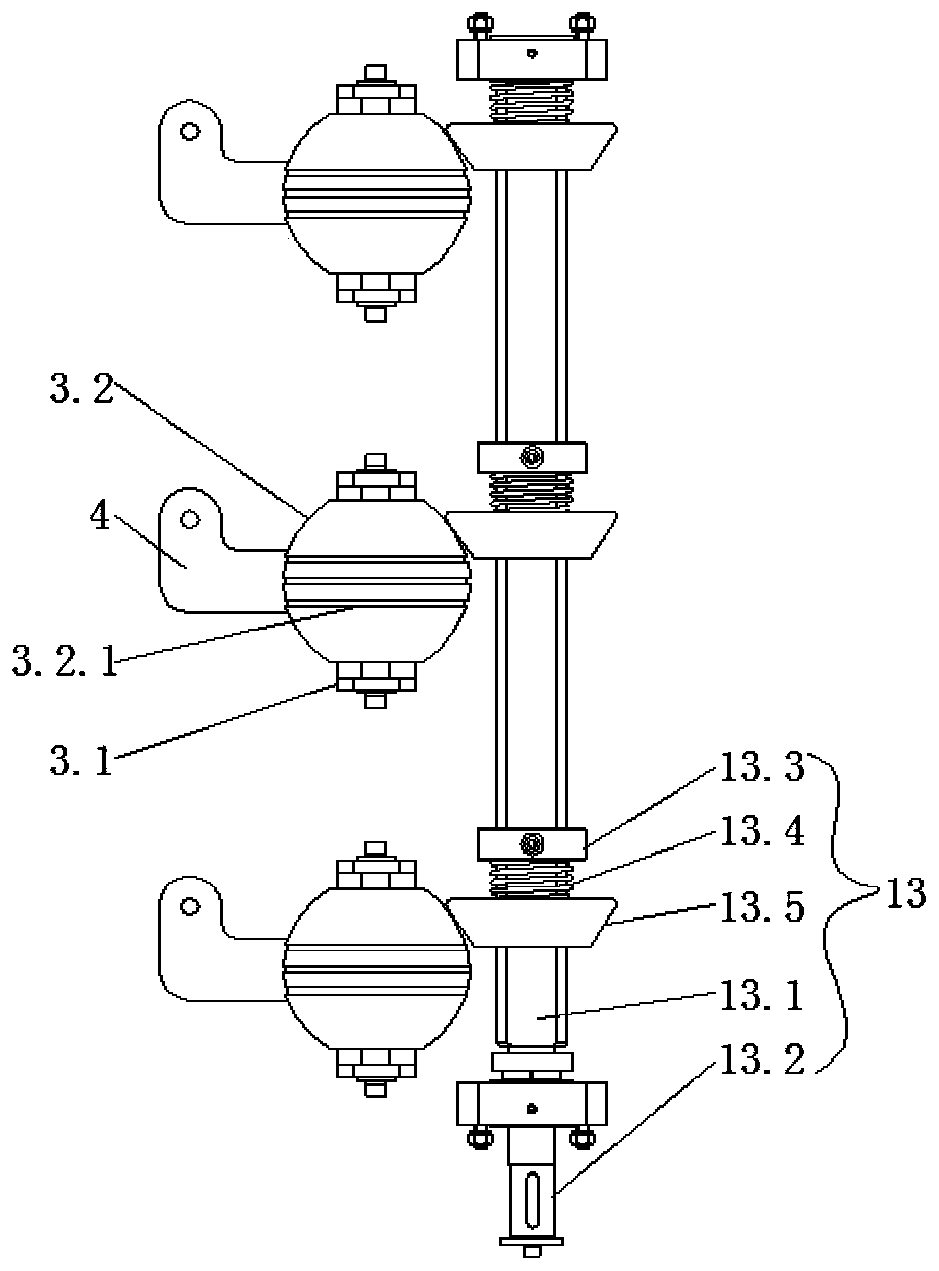

[0044] Such as Figures 1 to 7 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the deflection mechanism 3 includes a support frame 3.1, a deflection ball 3.2 is movably connected to the support frame 3.1, and the deflection ball 3.2 is connected to the bottom of the support frame 3.1. There is a gap between them, the bottom end of the support frame 3.1 is connected with the crank connecting rod A4, the bottom of the support frame 3.1 is connected with the rotating shaft 3.3, the rotating shaft 3.3 is movably connected on the main line frame 1, the bottom of the rotating shaft 3.3 is connected with the crank connecting rod B6, and the main line The frame 1 is rotatably provided with several drive mechanisms 13, the drive mechanism 13 is perpendicular to the length direction of the main line frame 1, and the drive mechanism 13 can drive the deflection balls 3.2 in the same horizontal row to rotate simultaneously, and the deflection angle...

Embodiment 3

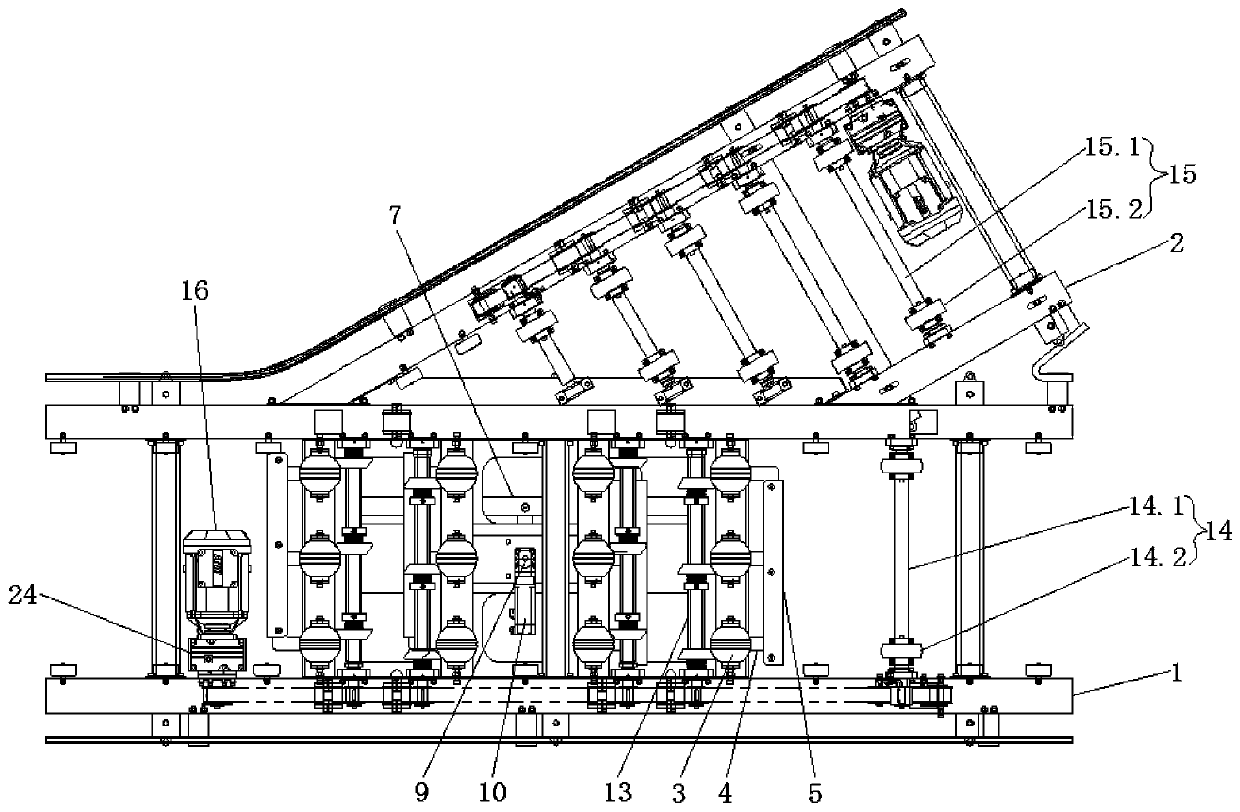

[0049] Such as Figures 1 to 11 As shown, this embodiment is further optimized on the basis of Embodiment 2. Specifically, the main line frame 1 is provided with a DC unit A14 located in front of the distribution unit along its conveying direction, and the branch line frame 2 is provided with DC unit B15, DC unit A14 includes a number of rollers A14.1 movably connected to the main line frame 1, at least two rollers A14.2 are fixedly sleeved on the roller A14.1, and DC unit B15 includes several rollers A14. The roller B15.1 on the branch line frame 2 has at least two rollers B15.2 fixedly sleeved on the roller B15.1.

[0050] The main line frame 1 is provided with a power unit that can drive the DC unit A14 and all driving mechanisms 13 to rotate. The power unit includes a driving motor B16 arranged on the main line frame 1. The driving motor B16 is connected to a reducer B24, and the reducer B24 is connected to There are driving wheels 17, and the side end of the main line fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com