Polar polymer microparticles, preparation method and use thereof

A polar polymer and micro-particle technology, applied in the directions of alkali metal compounds, chemical instruments and methods, water pollutants, etc., can solve the problems of high salinity, high concentration of organic chemical wastewater, difficult biodegradation of pollutants, etc., and achieve adsorption Large capacity, improved mass transfer efficiency, and the effect of increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

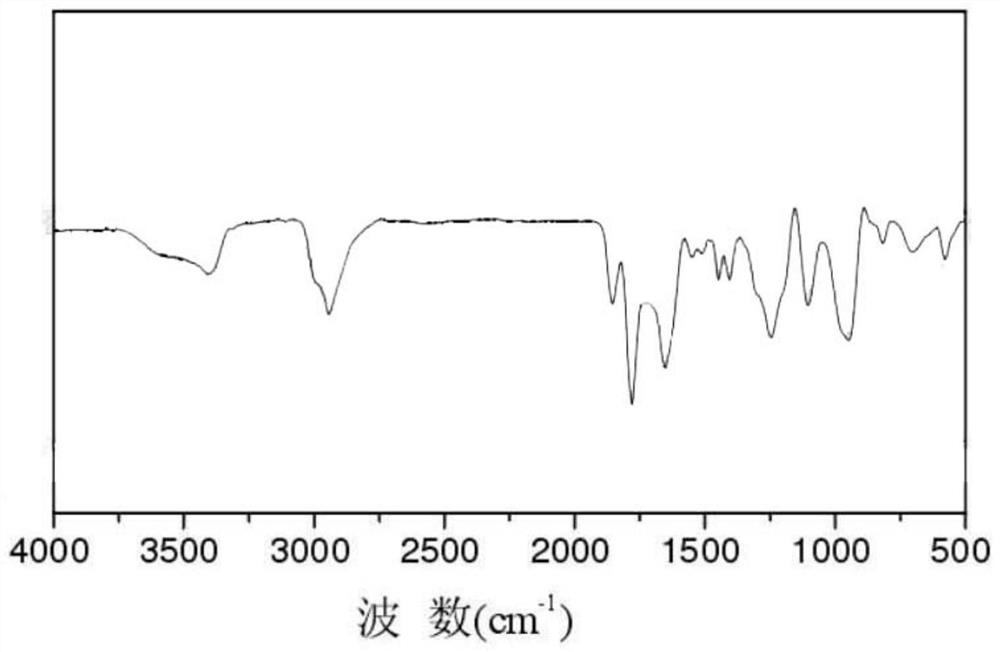

[0029] A preparation method for polar polymer microparticles, comprising the steps of:

[0030] 1) Prepare maleic anhydride, N-vinylpyrrolidone and vinyl ether in a molar ratio of 1:0.5-2:1;

[0031] 2) According to the solid-to-liquid ratio of 1:5-8 (g / mL), add maleic anhydride and organic solvent into the reaction vessel, and stir until MA is completely dissolved to form a clear and transparent homogeneous solution;

[0032] 3) Add N-vinylpyrrolidone, vinyl ether and initiator into the reaction vessel, pass nitrogen to empty, and mix uniformly to obtain a polymerization reaction system. The mass fraction of the initiator in the polymerization reaction system is 1-5%. When the mass fraction of the initiator is When the fraction is less than 1%, monodisperse microspheres cannot be obtained, but only some small random particles can be obtained. As the concentration of the initiator increases, the yield of the microspheres gradually increases. When the mass fraction of the initi...

Embodiment 2

[0040] A preparation method for polar polymer microparticles, comprising the steps of:

[0041] 1) Prepare maleic anhydride, N-vinylpyrrolidone and vinyl ether in a molar ratio of 1:1.2:1;

[0042] 2) According to the solid-to-liquid ratio of 1:6 (g / mL), add maleic anhydride and tetrahydrofuran into the three-necked flask, and stir until the MA is completely dissolved to form a clear and transparent homogeneous solution;

[0043] 3) Add N-vinylpyrrolidone, vinyl ether and lauroyl peroxide into the reaction vessel, pass nitrogen to empty, and mix uniformly to obtain a polymerization reaction system. The mass fraction of lauroyl peroxide in the polymerization reaction system is 1.5%;

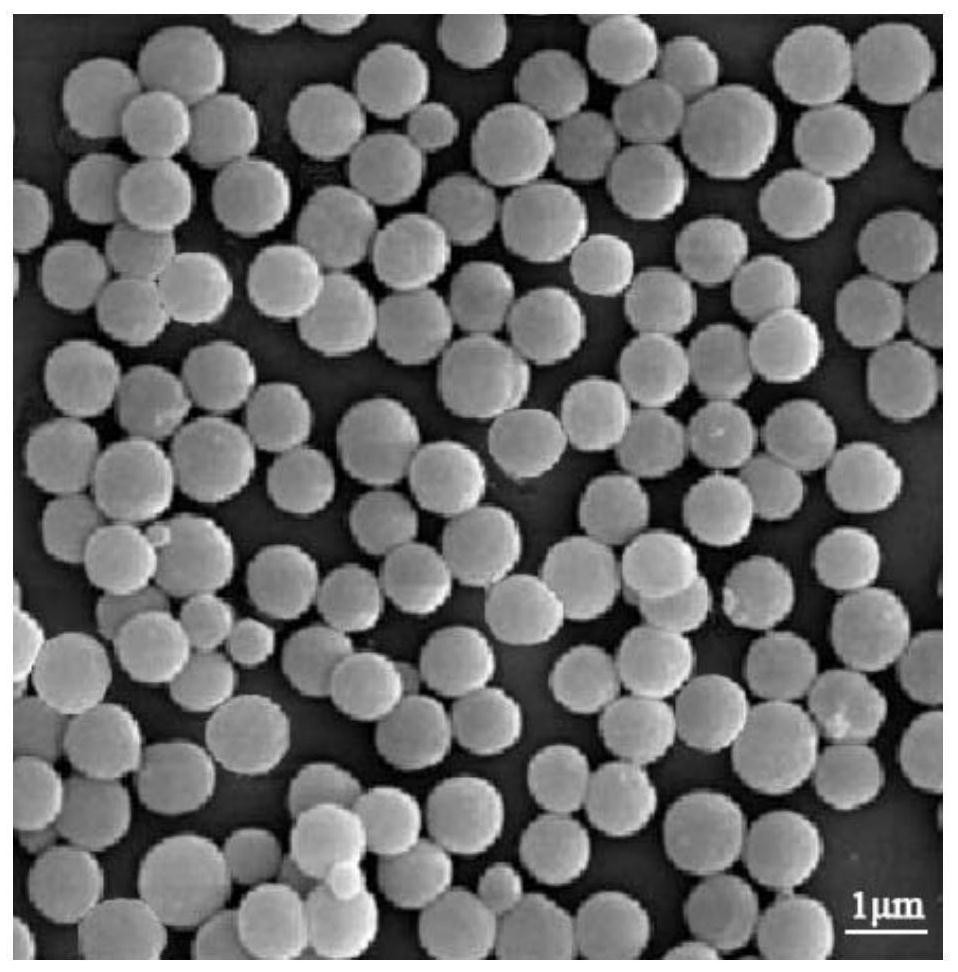

[0044] 4) The temperature of the polymerization reaction system was raised to 65°C within 30 minutes, and the reaction was stirred at a stirring speed of 500 rpm for 4 hours to undergo a polymerization reaction. After the reaction was completed, it was filtered, washed, and dried to obtain P(MA-DE...

Embodiment 3

[0046] A preparation method for polar polymer microparticles, comprising the steps of:

[0047] 1) Prepare maleic anhydride, N-vinylpyrrolidone and vinyl ether in a molar ratio of 1:1.2:1;

[0048] 2) According to the solid-to-liquid ratio of 1:6 (g / mL), add maleic anhydride and tetrahydrofuran into the three-necked flask, and stir until the MA is completely dissolved to form a clear and transparent homogeneous solution;

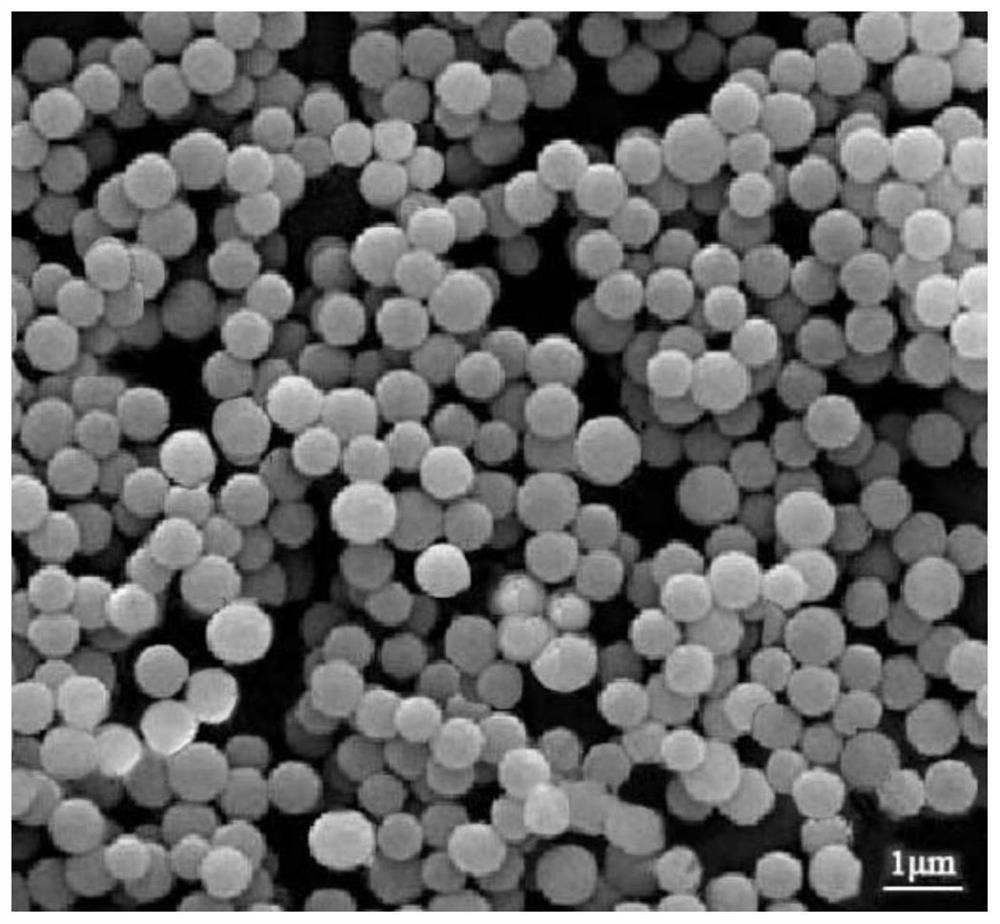

[0049] 3) Add N-vinylpyrrolidone, vinyl ether, lauroyl peroxide, hydroxyapatite and a-amino acid into the reaction vessel, pass nitrogen to empty, mix well to obtain a polymerization reaction system, and lauroyl peroxide in the polymerization reaction system The mass fraction of α-amino acid is 0.15%, the mass fraction of hydroxyapatite is 0.06%, and the mass fraction of a-amino acid is 1.5%;

[0050] 4) The temperature of the polymerization reaction system was raised to 65°C within 30 minutes, and the reaction was stirred at a stirring speed of 500 rpm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com