A kind of carbon nanotube predispersion for modified epoxy resin and preparation method thereof

A carbon nanotube and epoxy resin technology, applied in the field of materials, can solve the problems of carbon nanotubes, reduced dispersion problems, poor antistatic properties, etc., and achieves important commercial application value, less addition, and dispersion cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

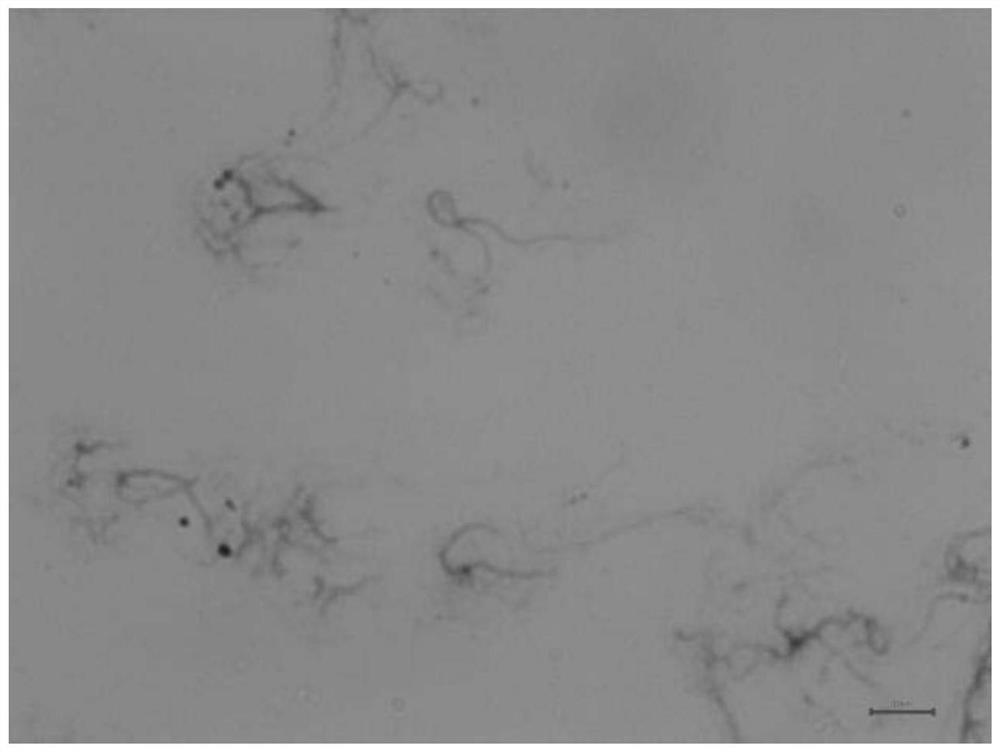

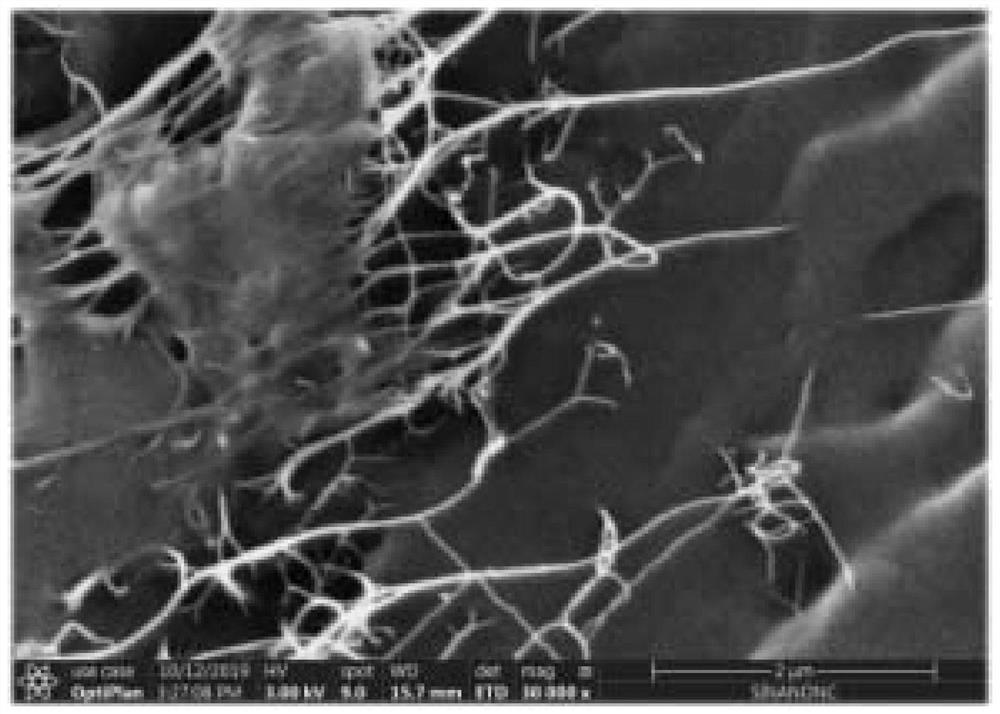

[0053] Step 1: Preparation of carbon nanotube epoxy predispersion

[0054] First, pour 10 g of carbon nanotubes with a diameter of 1 to 50 nm and a length of 0.1 to 50 μm, 70 g of epoxy oligomer, 5 g of a wetting agent, and 15 g of a dispersant into a beaker, and stir for 30 minutes with a high-speed mixer until they are mixed. uniform. Secondly, the uniformly mixed primary carbon tube pre-dispersion is subjected to high-strength grinding and shearing by using a CNC three-roller machine, and the entanglement is entangled by changing the speed and roller spacing of the feeding roller, middle roller, and discharging roller of the CNC three-roller machine. The carbon nanotubes are dispersed, and the grinding process parameters of the CNC three-roller machine: the gap between the feeding roller, the middle roller and the discharging roller is 30 μm; the speed of the rollers is 100 rpm, and the grinding is repeated once, and finally the carbon nanotubes are obtained. Tube predispe...

Embodiment 2

[0057] Step 1: Preparation of carbon nanotube epoxy predispersion

[0058] First, pour 10 g of carbon nanotubes with a diameter of 1 to 50 nm and a length of 0.1 to 50 μm, 70 g of epoxy oligomer, 5 g of a wetting agent, and 15 g of a dispersant into a beaker, and stir for 30 minutes with a high-speed mixer until they are mixed. uniform. Secondly, the uniformly mixed primary carbon tube pre-dispersion is subjected to high-strength grinding and shearing by using a CNC three-roller machine, and the entanglement is entangled by changing the speed and roller spacing of the feeding roller, middle roller, and discharging roller of the CNC three-roller machine. The carbon nanotubes are dispersed, and the grinding process parameters of the CNC three-roller machine: the gap between the feeding roller, the middle roller and the discharging roller is 20 μm; the roller speed is 200 rpm, and the grinding is repeated more than 2 times, and finally carbon Nanotube Predispersion.

[0059] St...

Embodiment 3

[0062] Step 1: Preparation of carbon nanotube epoxy predispersion

[0063] First, pour 10 g of carbon nanotubes with a diameter of 1 to 50 nm and a length of 0.1 to 50 μm, 70 g of epoxy oligomer, 5 g of a carbon tube wetting agent, and 15 g of a carbon tube dispersant into a beaker, and use a high-speed mixer to Stir for 30 minutes until the mixture is homogeneous. Secondly, the uniformly mixed primary carbon tube pre-dispersion is subjected to high-strength grinding and shearing by using a CNC three-roller machine, and the entanglement is entangled by changing the speed and roller spacing of the feeding roller, middle roller, and discharging roller of the CNC three-roller machine. The carbon nanotubes are dispersed, and the grinding process parameters of the CNC three-roller machine: the gap between the feeding roll, the middle roll and the discharge roll is 20 μm; the roll speed is 100 rpm, and the grinding is repeated for more than 3 times, and finally the carbon nanotubes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com