Multifunctional paste and preparation method thereof

A multi-functional and functional technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of mechanical performance decline, stirring difficulty, system viscosity increase, etc., and achieve long-lasting and stable antistatic performance, strong practicability, and good mechanical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

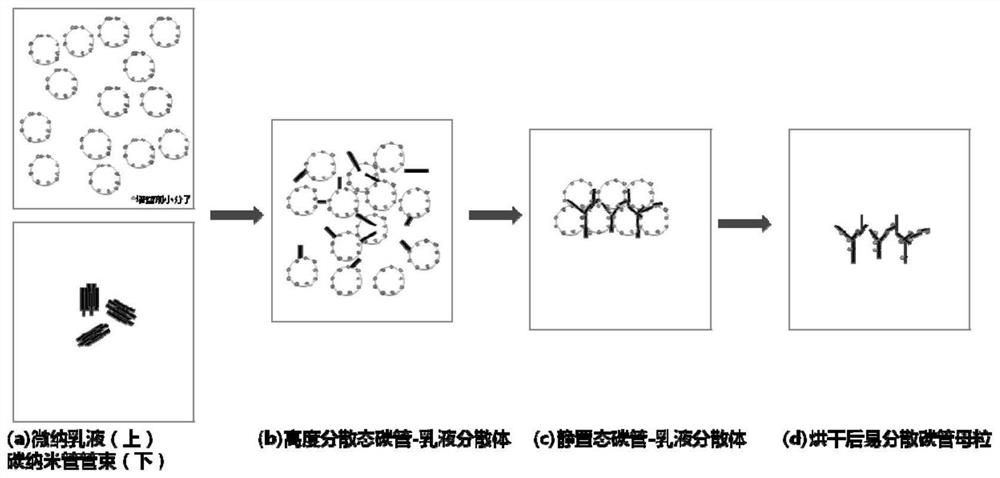

[0051] S1) Preparation of plasticizer emulsion;

[0052] S2) Carbon nanotube shear dispersion, dispersion concentration and drying;

[0053] S3) Preparation of multi-functional paste.

[0054] The specific steps of S1) are:

[0055] S1.1) In accordance with the design component, each material is weighed, and the environmentally friendly plasticizer is mixed with the emulsifier after the rotational speed is 500 ~ 3000R / min, the emulsification time is from 1 to 30 minutes.

[0056] After S1.2), the addition of anhydrous ethanol of the environmentally friendly plasticized dose is added, and the high-speed shear emulsification of the emulsified pump is activated 1 to 30 min, i.e., obtain a plasticizer emulsion.

[0057] The specific steps of S2) are:

[0058] S2.1) In the middle plasticizer emulsion obtained by adding carbon nanotubes to S1.2, at a rotational speed of 500 to 2000 r / min, the shear is dispersed from 1 to 30 minutes to obtain a dispersion;

[0059] S2.2) The dispersi...

Embodiment 1

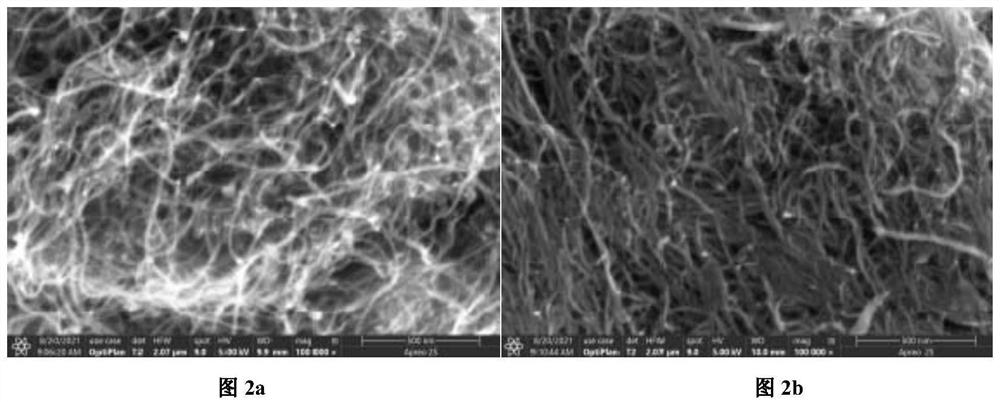

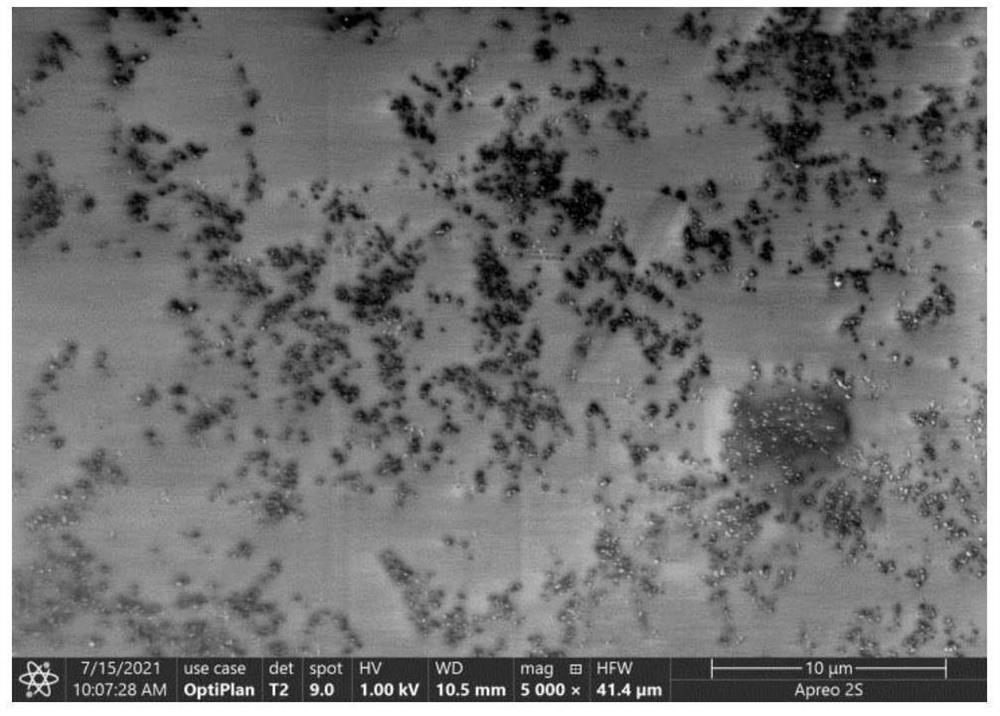

[0065] 50 DOTP plasticizers were mixed with 0.1 parts of polyether silicone emulsifier, slightly stirred, and transferred to an emulsified pump for strong emulsification for 3 min. After the mixing was completed, it was poured into a 5L container having 200 parts of ethanol to form a coarse dispersion emulsion. The high-speed dispersing machine is opened, maintaining the rotational speed at 1500r / min, using high-speed mixing pad to cut the coarsely dispersed emulsion to disperse 10 min to obtain a micro-nanotic emulsion. After reaching the predetermined mixing time, stop stirring, add 10 multi-walled carbon nanotubes to the emulsion GT300, continued to stir at high speed to disperse 20 min, stop stirring again. The transfer of free ethanol was separated from the mixed liquid transfer after the secondary dispersion to obtain a concentrated paste. The concentrated paste was transferred to an oven at 110 ° C, baked for 8 h. After collecting the fully dried material, transfer to th...

Embodiment 2

[0067] 100 parts of DINCH plasticizer were mixed with 1 part of alkylphenol polyoxyethylene ether emulsifier, and after stirring, transferred to an emulsion pump for strong emulsion mixing for 3 min. After the mixing was completed, it was poured into a 5L container having 1000 parts of ethanol to form a coarse dispersion emulsion. The high-speed dispersing machine is opened, maintaining the rotational speed at 1500r / min, using high-speed mixing pad to cut the coarsely dispersed emulsion to disperse 10 min to obtain a micro-nanotic emulsion. After the predetermined agitation time is reached, stir it, and 50 parts of multi-walled carbon nanotubes are added to the emulsion. NC7000, continued to stir the dispersion of 20 min after high speed, stop stirring again. The transfer of free ethanol was separated from the mixed liquid transfer after the secondary dispersion to obtain a concentrated paste. The concentrated paste was transferred to an oven at 110 ° C, baked for 8 h. After co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com