High-temperature-resistant adhesive

An adhesive and high-temperature-resistant technology, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of affecting the performance of electronic components, affecting the bonding strength of adhesives, and affecting the performance of adhesives. Enhance the bonding strength, prolong the service life, and enhance the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

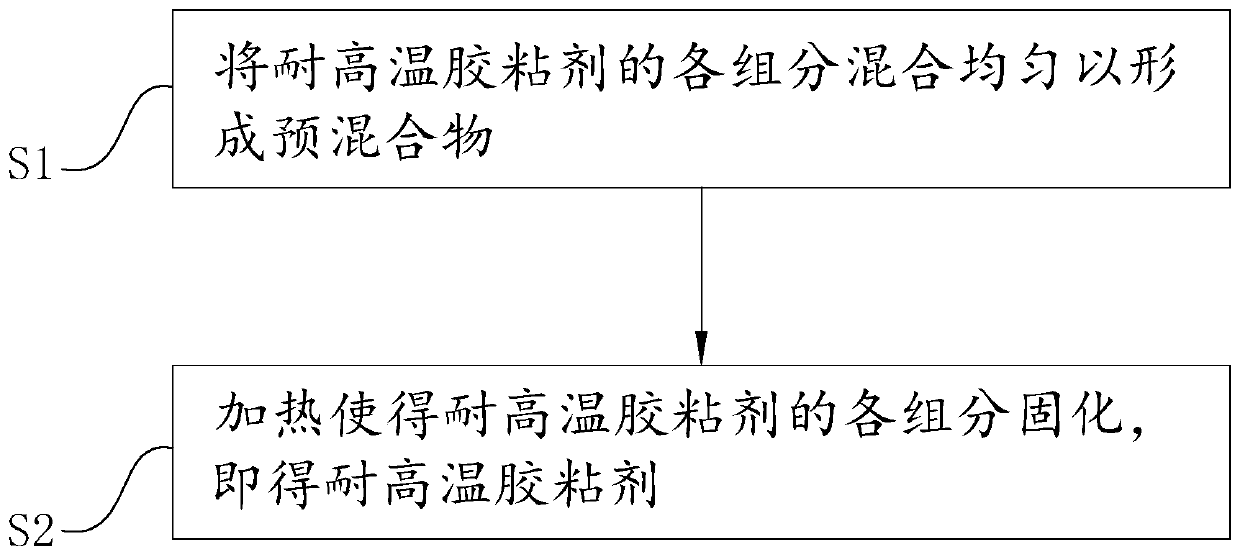

[0062] A preparation method of high temperature resistant adhesive, comprising the following steps:

[0063] S1, raw material mixing, specifically as follows:

[0064] In a 150L stirred tank, under normal temperature conditions, add 65kg of bisphenol A epoxy resin, stir at a speed of 1000r / min, add 15kg of dimethylimidazole, 27.5kg of calcined alumina, and 5kg of novolak epoxy resin while stirring, Stir for 15 min to form a premix.

[0065] S2, curing into glue, specifically as follows:

[0066] Heat the pre-mixture at 115°C for 35 minutes to cure the pre-mixture to obtain a high temperature resistant adhesive.

Embodiment 2

[0068] The difference with embodiment 1 is:

[0069] S1, raw material mixing, specifically as follows:

[0070] In a 150L stirred tank, under normal temperature conditions, add 60kg of bisphenol A epoxy resin, stir at a speed of 1000r / min, add 10kg of dimethylimidazole, 35kg of calcined alumina, and 7.5kg of novolak epoxy resin while stirring, Stir for 15 min to form a premix.

Embodiment 3

[0072] The difference with embodiment 1 is:

[0073] S1, raw material mixing, specifically as follows:

[0074] In a 150L stirred tank, under normal temperature conditions, add 70kg of bisphenol A epoxy resin, stir at a speed of 1000r / min, add 12.5kg of dimethylimidazole, 20kg of calcined alumina, and 10kg of novolac epoxy resin while stirring, Stir for 15 min to form a premix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com