Electric-control rotary lifting type steel platform integral lifting device and construction method thereof

An overall lifting and steel platform technology, which is applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., can solve problems such as the need for manual assistance, the self-heavyness of lifting equipment, and discontinuous lifting, so as to avoid Frustration and vibration, precise control of lifting state, effects that are beneficial to safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

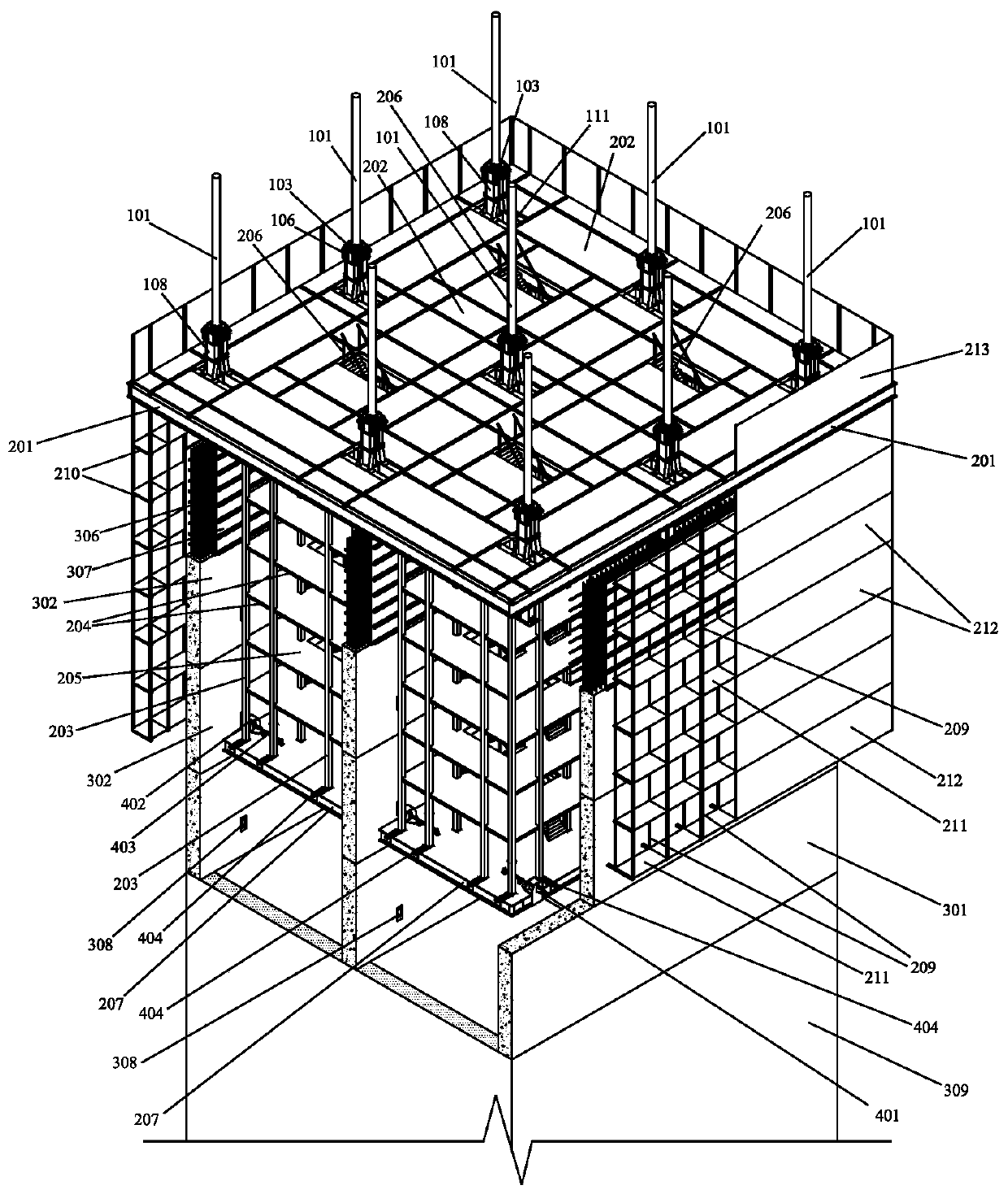

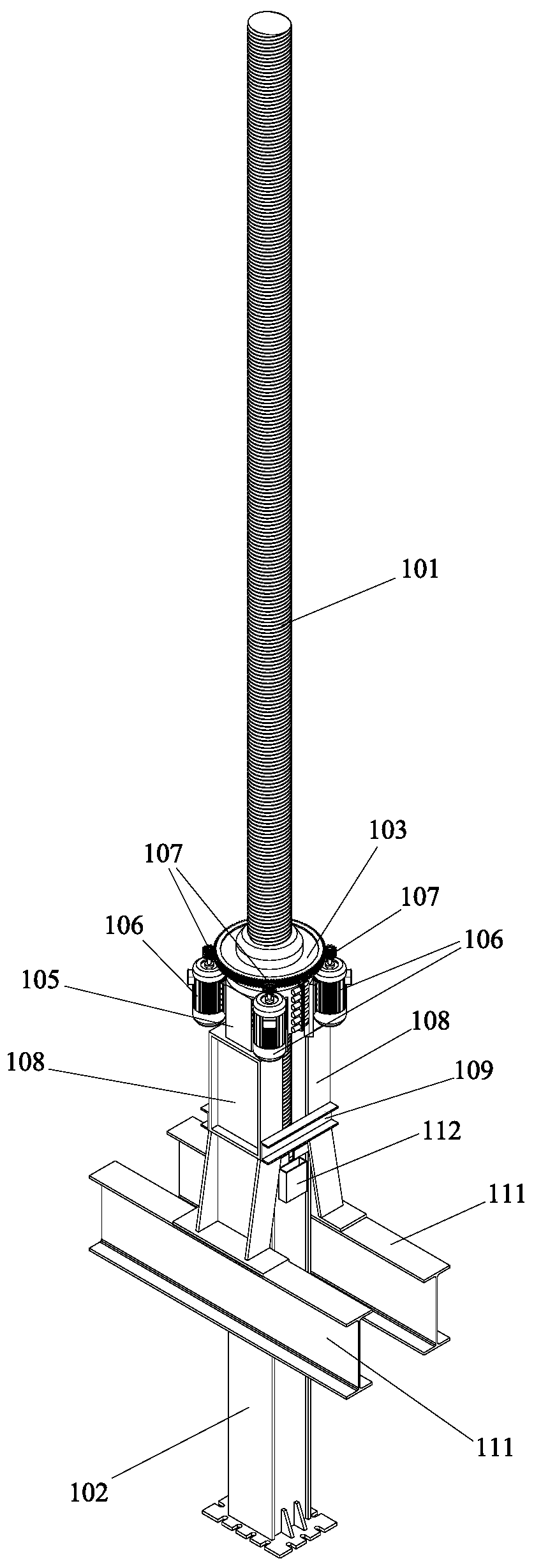

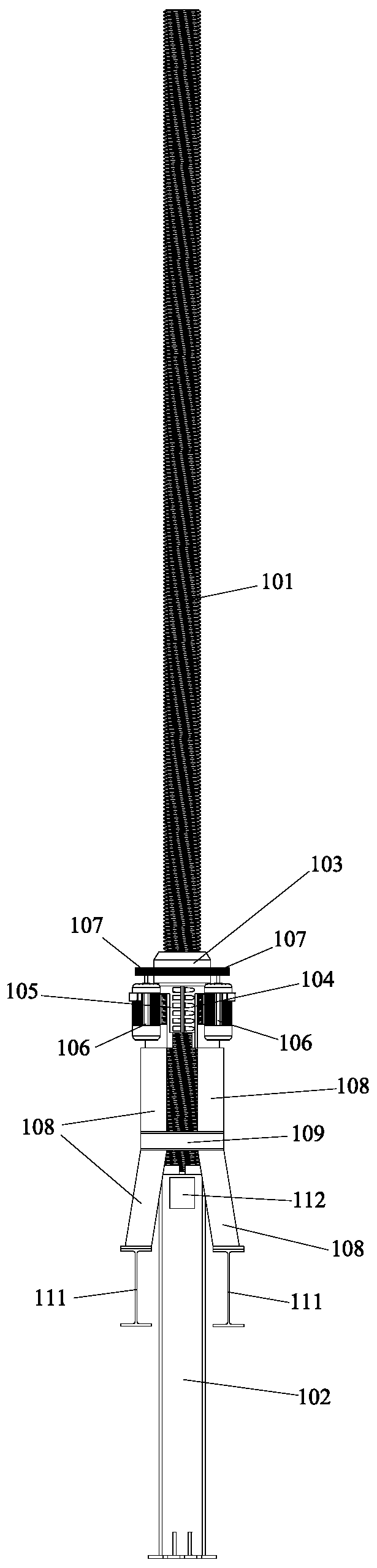

[0044] Please refer to Figure 1 to Figure 14 , A detailed description of the electronically controlled rotary-lift steel platform integral lifting device and construction method of the present invention.

[0045] Such as Figure 1 to Figure 14 As shown, the core tube of this embodiment has a Tian-shaped configuration. The core tube has four inner tubes. The standard layer of the core tube has a height of 3.9m. In the n+1 section of the core tube, the standard layer 301 and the core tube A number of corbel bearing pin shells 308 are provided at the lower part of the inner cylinder side wall of the n+2 section standard layer 302, the core tube n+3 section standard layer 303, and the core tube n+4 section standard layer 304. The corbel bearing pin shell 308 is a trough-shaped prefabricated steel member, which is used to extend and rest the corbel 401 during the core tube reinforced concrete pouring stage. The resting corbel 401 transfers the load of the entire steel platform it bea...

Embodiment 2

[0057] Please continue to refer Figure 1 to 14 This embodiment provides a construction method for constructing the core tube structure of a super high-rise building. The main steps of the construction method are as follows:

[0058] Step 1: Complete the combined installation of the spin-up system, steel platform system, and bottom support system according to the design requirements to meet all the conditions for carrying out the construction of the super high-rise core tube structure; at this time, the shelving corbel 401 is located in the n+1 section of the core tube Within the corbel bearing pin shell 308 on the inner cylinder wall of the standard layer 301; the lifting steel template 307 is fixed on the n+3 section standard layer 303 of the core cylinder. The n+3 section standard layer 303 of the core cylinder has sufficient strength.

[0059] Step 2: Improve preparation. Firmly fix the lifting column support 102 on the upper end of the standard layer 303 of the n+3 section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com