Improved method and structure of plug valve

A plug valve and valve body technology, which is applied to the valve shell structure, the plug including the cut-off device, and the valve details, etc., can solve the problems of non-uniform structure, inconvenient disassembly and assembly, unstable pressure test, etc. The effect of saving pressing time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

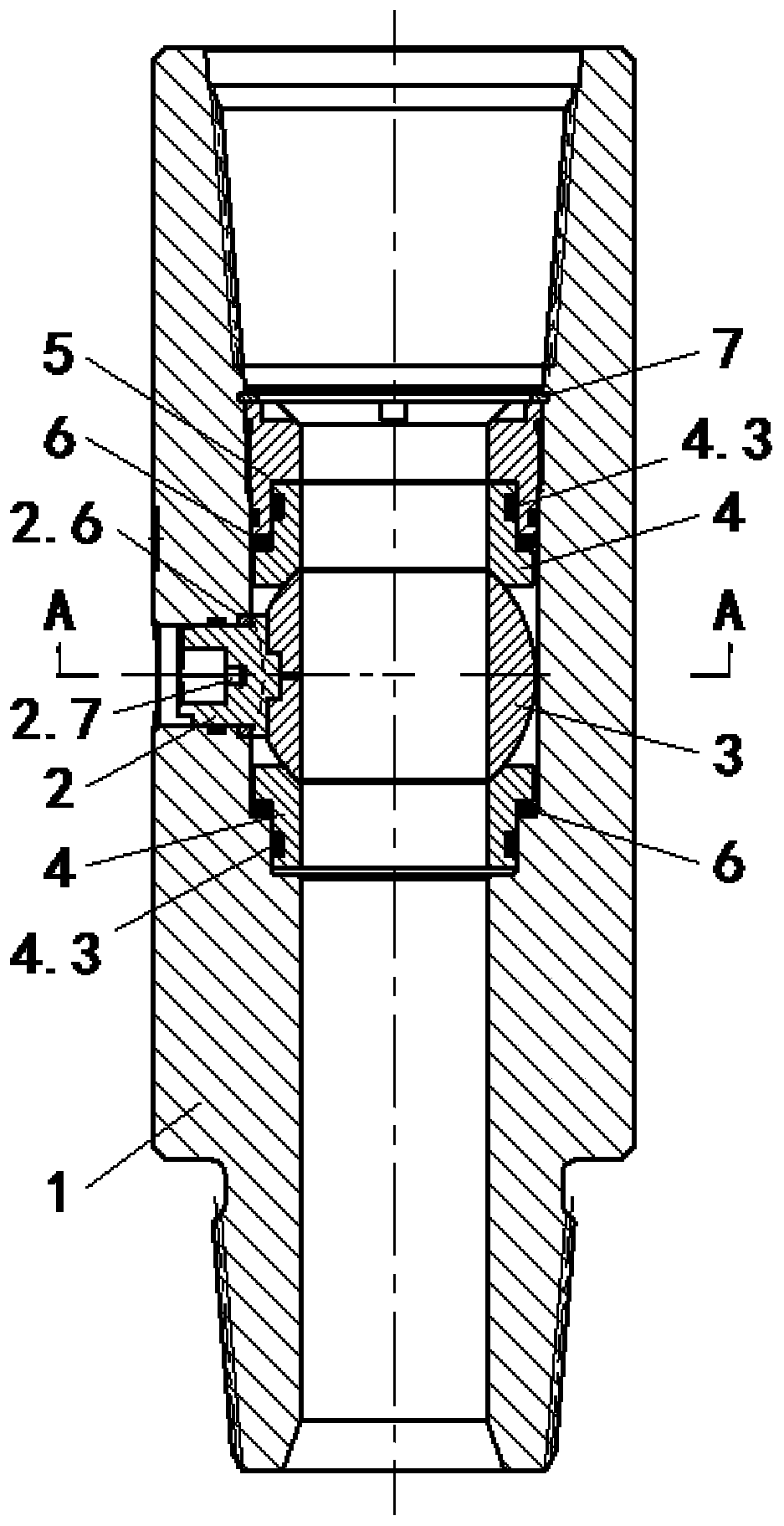

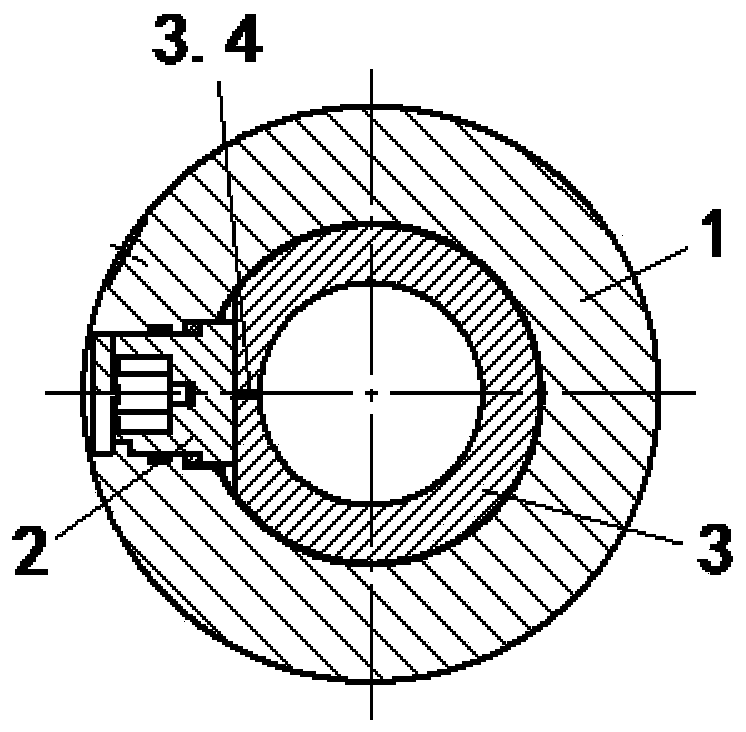

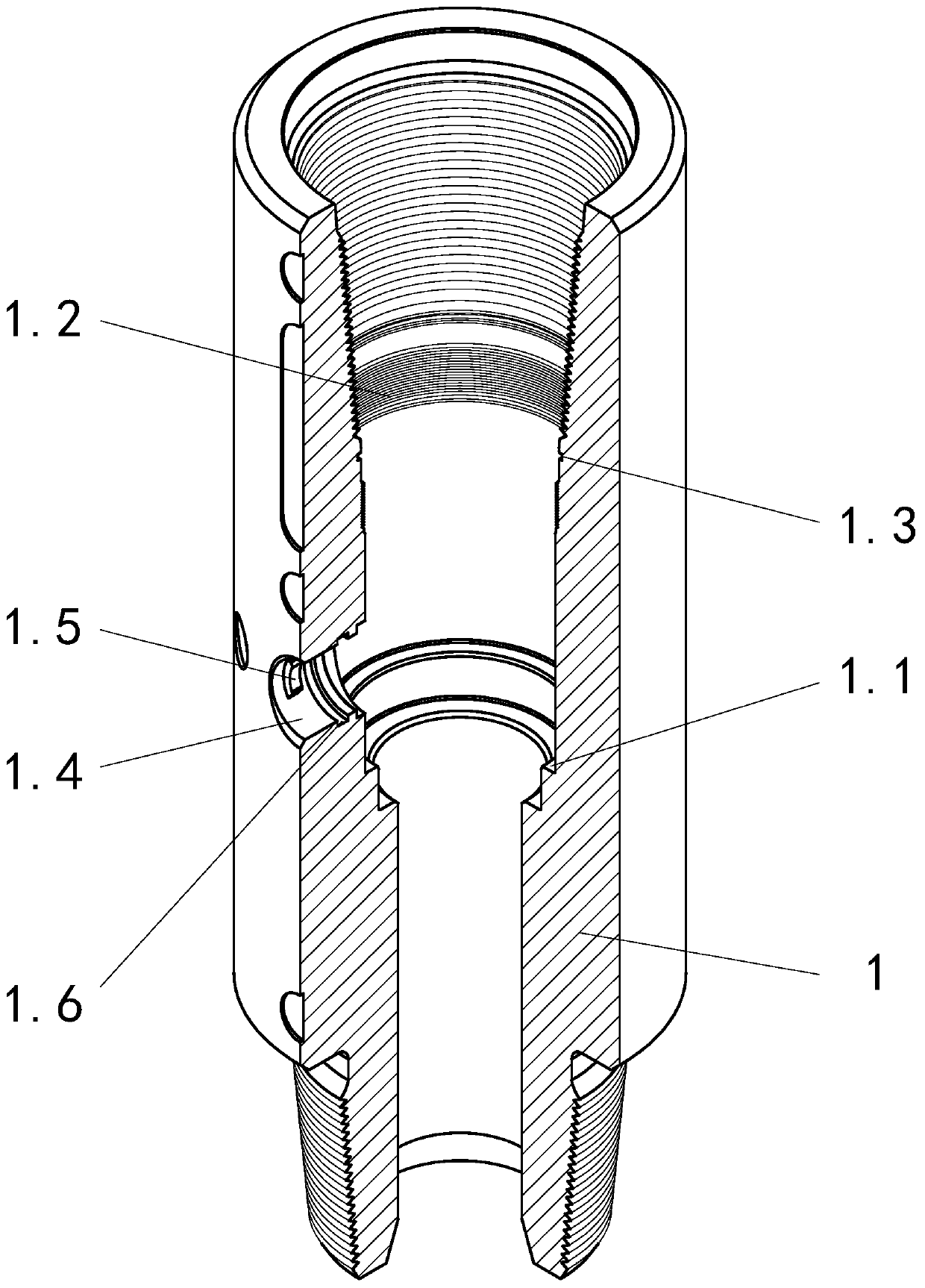

[0028] The improved method of a kind of plug valve of the present invention, as figure 1 with figure 2 As shown, the method is to set a limit boss at the orifice of the operation hole of the valve body, and set an arc-shaped limit groove on the operation key at the same time, through the limit boss of the operation orifice on the valve body and the operation key The rotation of the upper arc-shaped limit groove makes the operation key only rotate within the range of 90 degrees. At the same time, the bottom of the operation key is connected with the keyway on the valve core through a straight convex key to realize the opening and closing function of the cock valve structure. ;The quantity of the limit boss at the operating orifice on the valve body and the number of limit grooves of the operation key are 1 to 3; in addition, a limit ring is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com