Direct current steam generator

A steam generator and burner technology, applied in steam generation, steam boilers, lighting and heating equipment, etc., can solve the problems of high operating cost, long start-up time, low reliability, etc., to avoid steam explosion, improve thermal efficiency, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

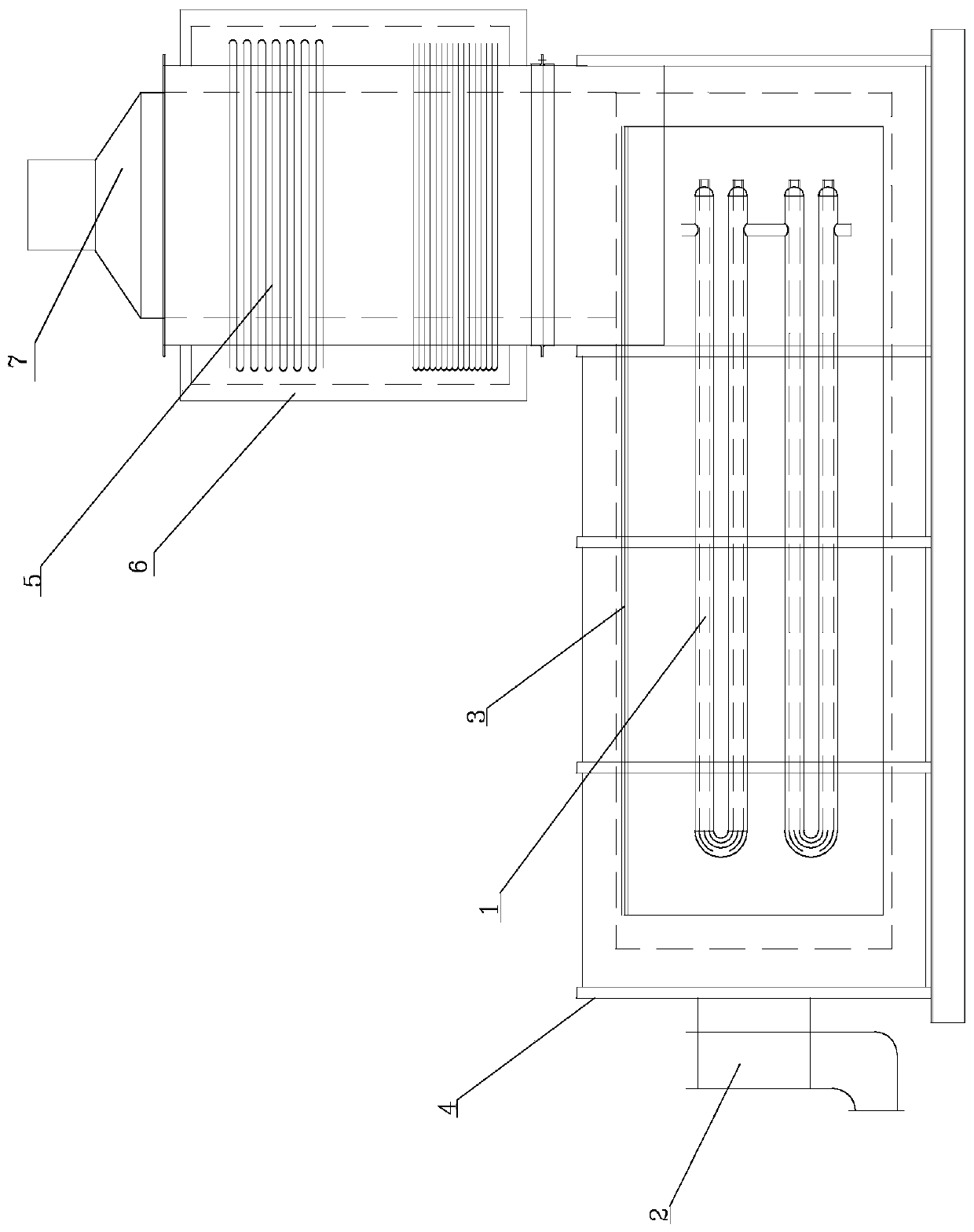

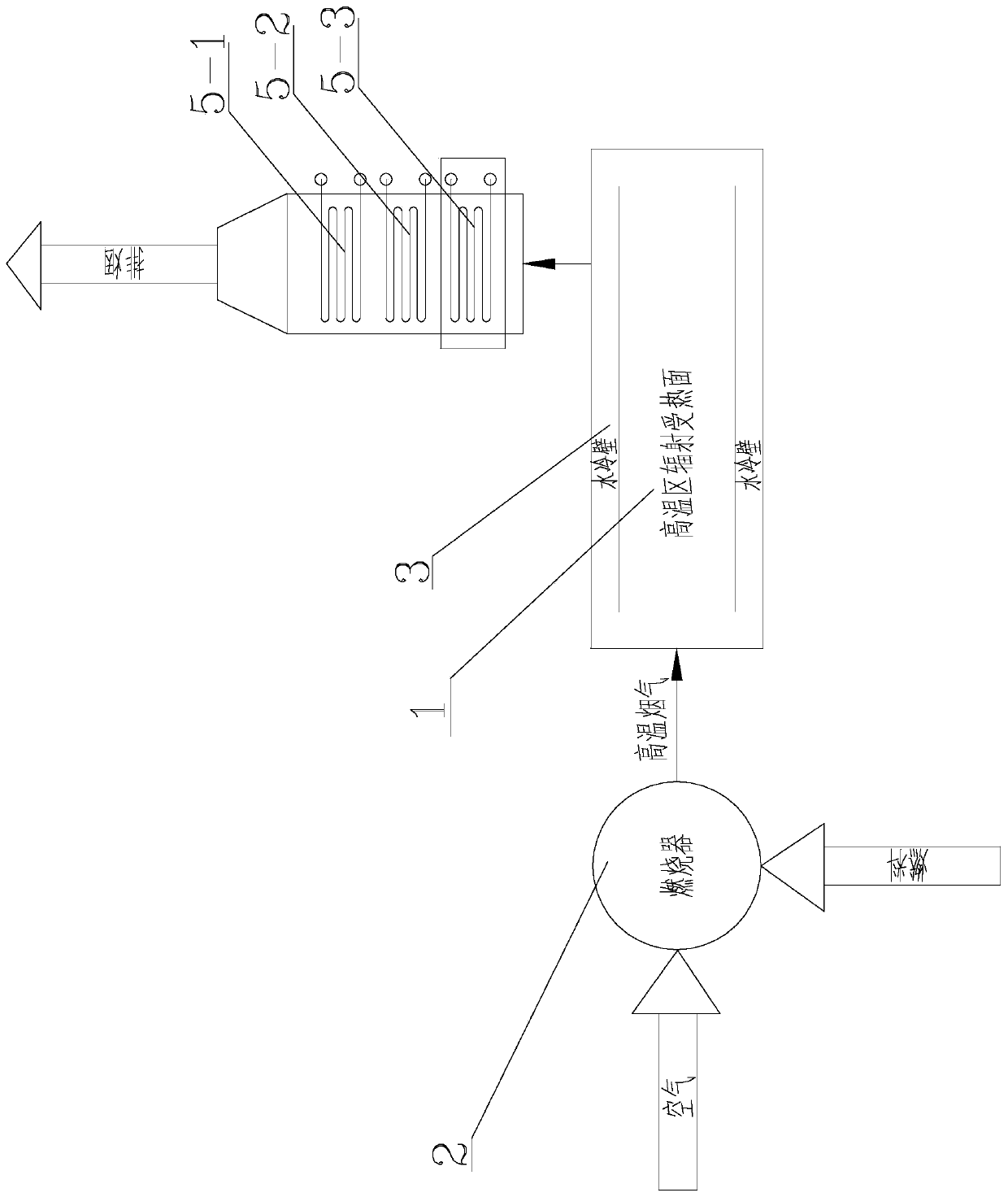

[0023] Specific implementation mode one: combine Figure 1 to Figure 4 To illustrate this embodiment, a once-through steam generator described in this embodiment includes a radiation heat receiving pipe 1 in a high temperature zone, a burner 2, a water wall 3, a lower part of the housing 4, a convective heating unit 5 in a low temperature zone, and an upper part 6 of the housing;

[0024] The lower part 4 of the housing is cylindrical, and one end of the lower part 4 of the housing is provided with a burner 2, and the burner is connected to the lower part 4 of the housing, and the lower part 4 of the housing is provided with n high-temperature zone radiation heat receiving pipes 1, n It is a positive integer and arranged in parallel. The inner wall of the lower part of the housing 4 is evenly provided with m water-cooled walls 3 along the circumferential direction, m is a positive integer, and the other end of the lower part of the housing 4 is provided with an upper part of th...

specific Embodiment approach 2

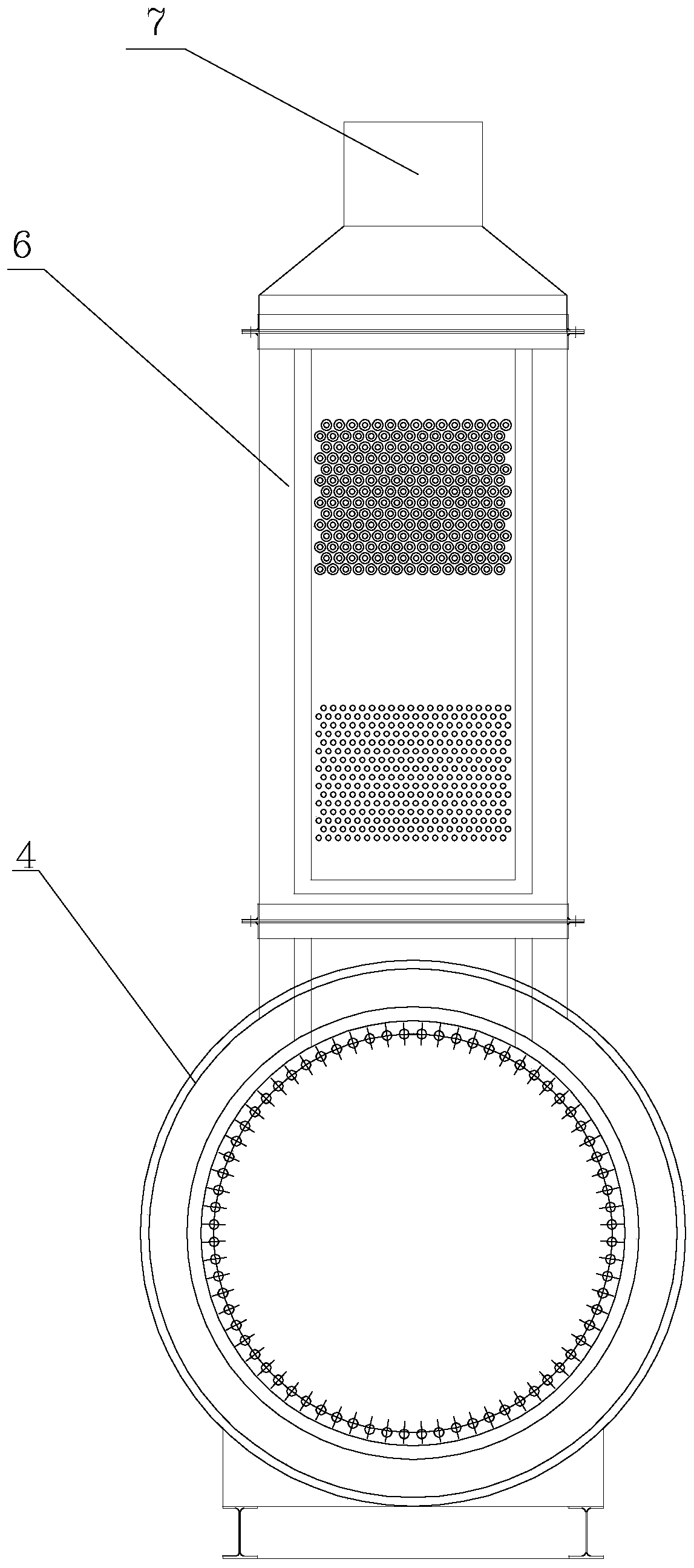

[0026] Specific implementation mode two: combination figure 2 Describe this embodiment. This embodiment is a further limitation on the generator described in Embodiment 1. In the direct-flow steam generator described in this embodiment, the top end of the lower part 4 of the housing is provided with a smoke exhaust Mouth 7.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 2 Describe this embodiment, this embodiment is a further limitation on the generator described in the second specific embodiment, a direct-flow steam generator described in this embodiment, the smoke exhaust port 7 is a tapered port;

[0028] In this specific embodiment, the smoke exhaust port 7 is adopted as a tapered port, so that the smoke can be discharged in one place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com