Detector for low-speed drop hammer impact test of circular pipe fitting and impact test instrument

A drop-weight impact test and detection device technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problem of inability to accurately measure the deflection of pipe fittings, and achieve the effect of small measurement error and overcoming the friction of guide rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

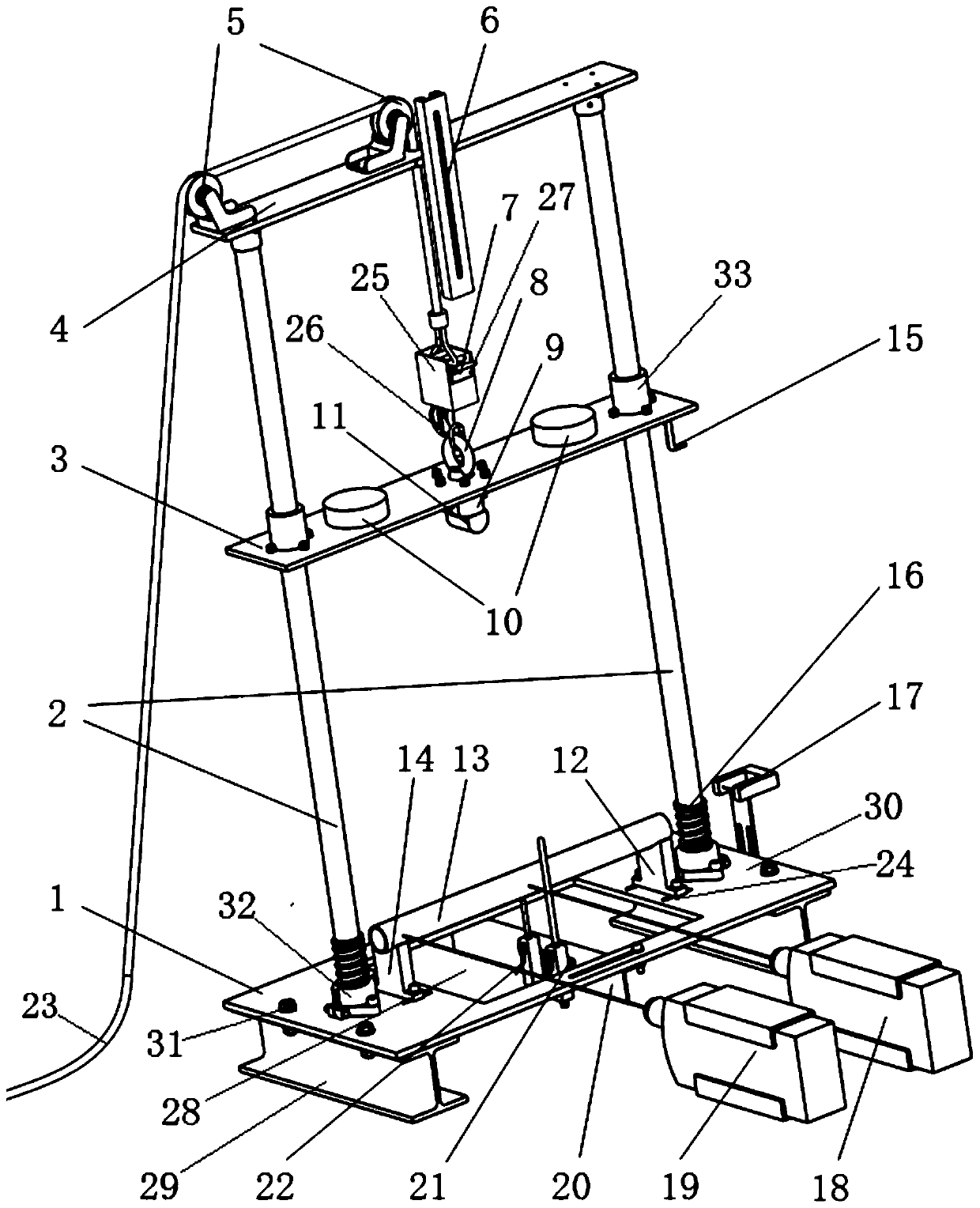

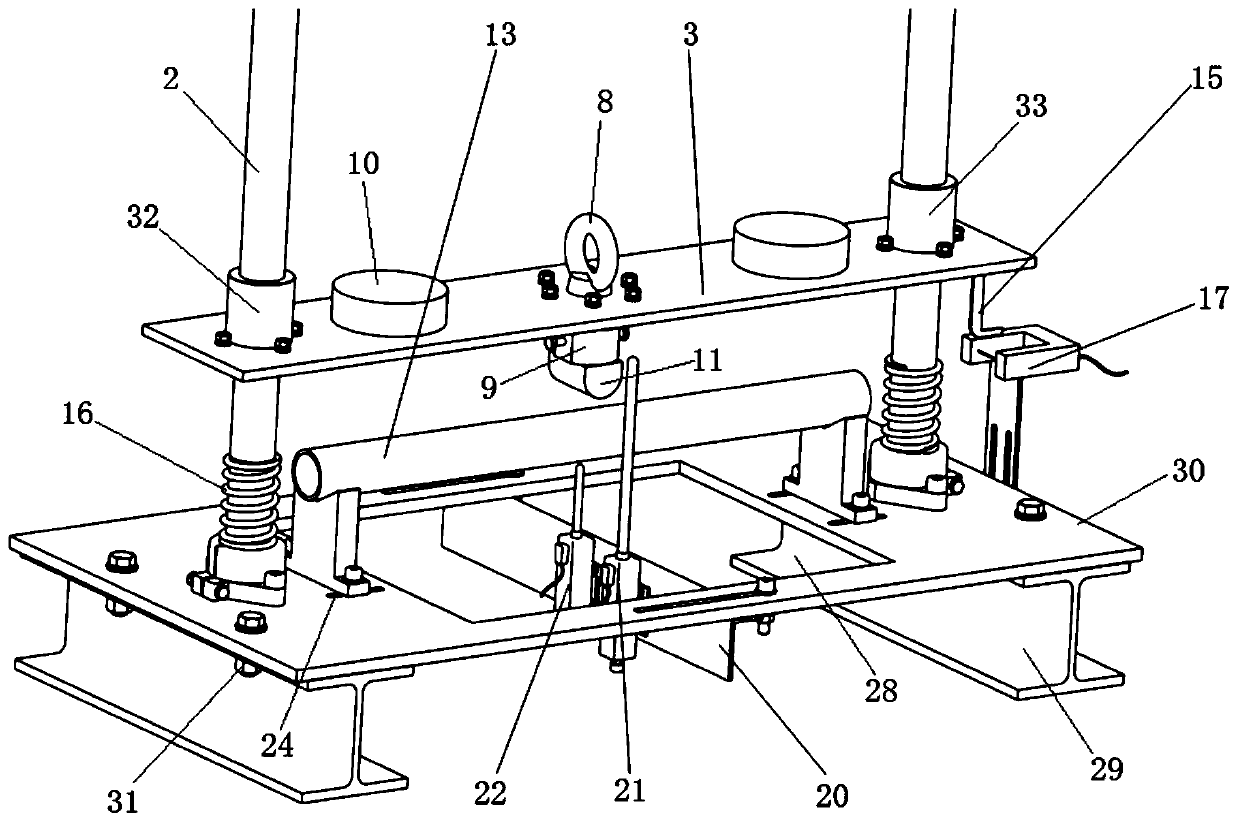

[0056] see figure 1 as well as figure 2 , the present invention provides a circular pipe fitting low-speed drop weight impact test detection device, the test detection device can detect the circular pipe fitting 13 to be tested, to detect the impact performance parameters of the circular pipe fitting, so as to obtain Prepare for impact-resistant pipe fittings with high specific modulus and specific strength. Wherein, the test detection device includes a test bench assembly, a drop hammer impact assembly, a vibration signal measurement assembly and a displacement signal measurement assembly.

[0057] The test bench assembly includes a base 1, a sliding guide rod 2, a material receiving mechanism and a photoelectric door 17, and may also include an upper plate frame 4, a height limiting plate 6, an automatic decoupling device 7, a rope 23, a fixed pulley 5 and a buffer spring 16. In this embodiment, the base 1 includes I-shaped steel 29, steel plates 30, bolts 31 and shock-ab...

Embodiment 2

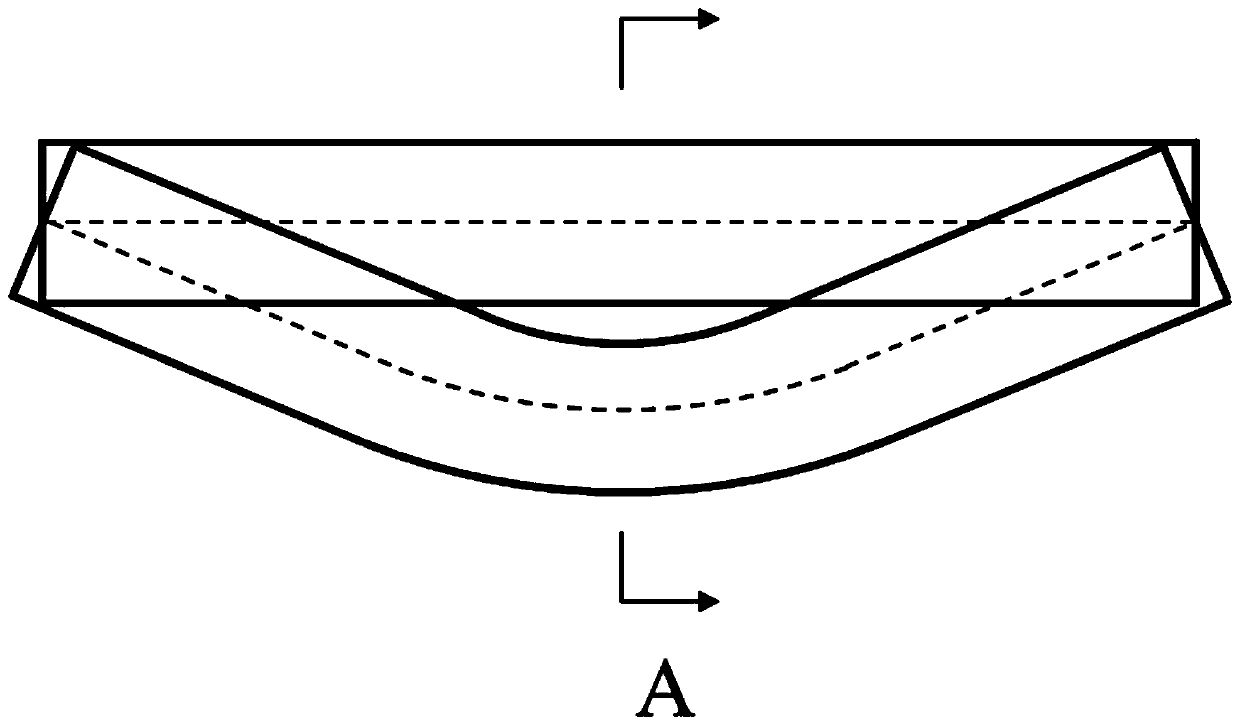

[0075] see image 3 as well as Figure 4 , this embodiment provides a low-speed drop-weight impact test detection device for circular pipe fittings. On the basis of Embodiment 1, the detection device adds a deformation calculation mechanism belonging to the displacement signal measurement component. The deformation calculation mechanism is used to calculate the deformation of the impact point where the hammer head 11 hammers the circular pipe 13, and the calculation formula is:

[0076] δ d =(δ-d 1 )-(ω-d 2 )

[0077] Among them, δ d is the deformation at the point of impact. When the hammer head 11 hammers the circular pipe 13, the displacement of the impact plate 3 is δ, and the displacement of the measuring point is ω. When the hammer head 11 falls on the circular pipe 13 with the impact velocity being zero, the displacement of the impact plate 3 is d 1 , the displacement of the measuring point is d 2 . It should be noted here that the above calculation formula ca...

Embodiment 3

[0080] This embodiment provides a low-velocity drop weight impact test instrument for circular pipe fittings, which includes a detection device and a data processing device. Wherein, the detection device is the low-speed drop weight impact test detection device for circular pipe fittings in Embodiment 1 or Embodiment 2. The data processing device is used to obtain the impact reaction force detected by the force sensor 9, the impact velocity of the light-shielding sheet 15, the vibration amount detected by the vibration signal measuring component, and the displacement detected by the displacement signal measuring component, and generate the impact deflection of the circular pipe 13.

[0081] Of course, the data processing device can also be used to record data such as impact reaction force, impact velocity, vibration and displacement in a parameter statistics table preset inside it, and correspond to the type and measuring point of the circular pipe 13 position, to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com