Method and device for testing longitudinal variation performance of pyrolysis process of production coal

A technology of longitudinal change and coal pyrolysis, applied in the direction of material thermal expansion coefficient, etc., can solve the problem of losing control of the temperature system, and achieve the effects of ensuring effective forward movement, reducing difficult coke pushing process, and effective coal blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

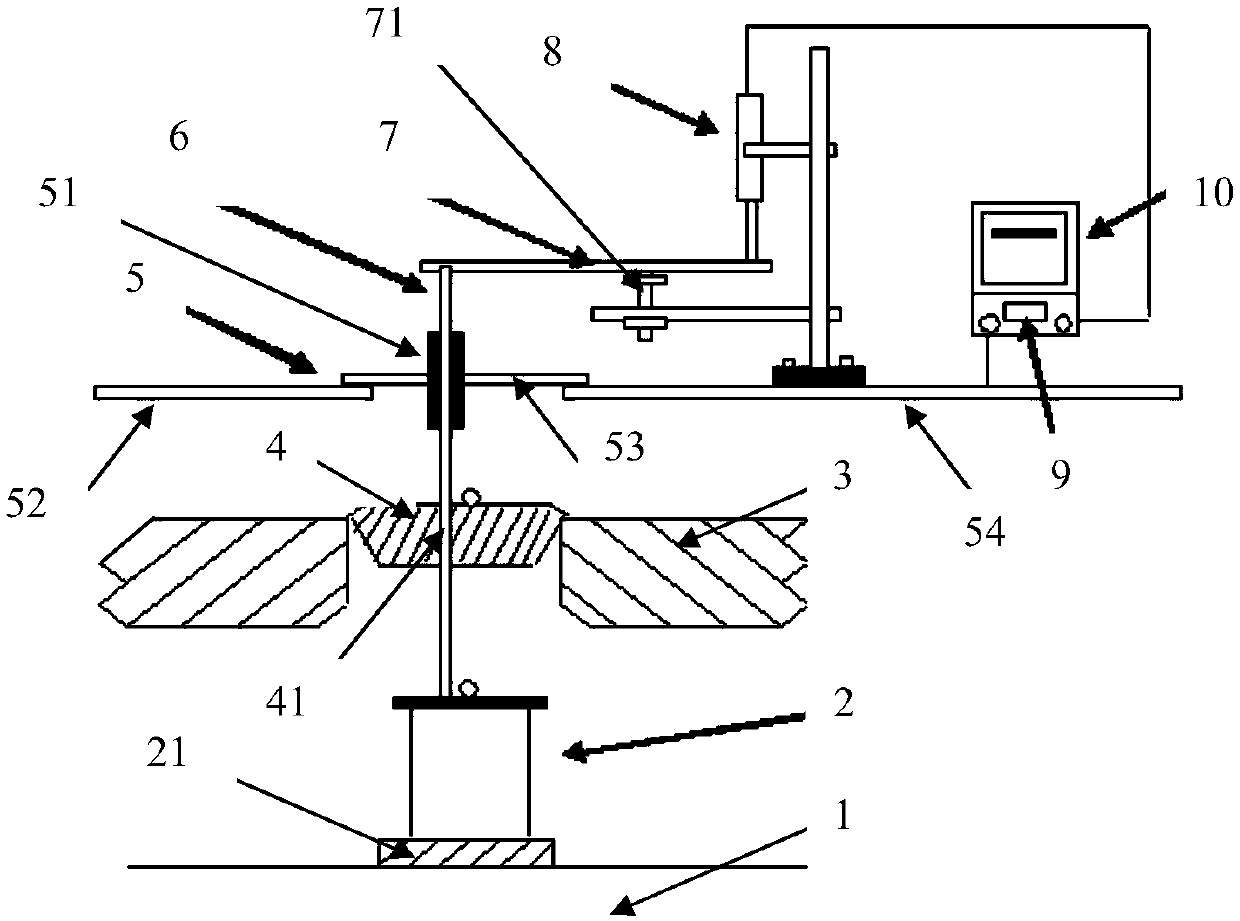

Embodiment 1

[0042] Will A d content of 7%, V d Put 100kg of 30% test coal samples with 83% particle size less than 3mm into a 100kg top-loaded test coke oven, adopt the natural falling method from the coke oven coal charging port, and the natural bulk density of the furnace coal is about 820kg / m 3 . After the coal sample is loaded, use a flat coal rod to spread the loaded coal from the coal charging port on the upper part of the coke oven, and then install a longitudinal change detection device for production coal at the coal charging port on the top of the coke oven. The roughness Ra of the steel plate surface in contact with coal is 2.6. The furnace coal is heated at a heating rate of 2°C / min, and the heating is stopped when the center temperature of the coke cake reaches 1000°C. Record the measurement results, and the maximum shrinkage rate in the longitudinal direction is 54%.

Embodiment 2

[0044] Will A d content of 9%, V d 90kg of 28% test coal samples with 85% particle size less than 3mm were put into a 100kg top-loaded test coke oven, and the material was naturally dropped from the coke oven coal charging port, and the natural bulk density of the furnace coal was about 825kg / m 3 . After the coal sample is loaded, use a flat coal rod to spread the loaded coal from the coal charging port on the upper part of the coke oven, and then install a longitudinal change detection device for production coal at the coal charging port on the top of the coke oven. The roughness Ra of the steel plate surface in contact with coal is 2.7. The furnace coal is heated at a heating rate of 3°C / min, and the heating is stopped when the center temperature of the coke cake reaches 1020°C. Record the measurement results, and the maximum shrinkage rate in the longitudinal direction is 38%.

Embodiment 3

[0046] Will A d content is 10%, V d 80kg of 86% test coal samples with a particle size of less than 3mm at a content of 28% were put into a 100kg top-loaded test coke oven, and the material was naturally dropped from the coke oven coal charging port, and the natural bulk density of the furnace coal was about 830kg / m 3 . After the coal sample is loaded, use a flat coal rod to spread the loaded coal from the coal charging port on the upper part of the coke oven, and then install a longitudinal change detection device for production coal at the coal charging port on the top of the coke oven. The roughness Ra of the steel plate surface in contact with coal is 2.8. The furnace coal is heated at a heating rate of 4°C / min, and the heating is stopped when the center temperature of the coke cake reaches 1050°C. The measurement results were recorded, and the maximum shrinkage rate in the longitudinal direction was tested to be 41%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com