Manufacturing method of silicon epitaxial wafer for 8-inch VDMOS power tube

A technology of silicon epitaxial wafers and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as uneven resistivity of epitaxial layers, achieve improved impurity distribution, increase yield, and reduce transition zone width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] The manufacture method of 8 inches VDMOS power tube silicon epitaxial wafers of the present invention, comprises the following steps:

[0024] (1) As-doped substrate is selected, and the resistivity is ≤0.004Ω.cm; the back of the substrate is made of silicon dioxide (LTO) + polysilicon (Poly) back seal; the edge width of the back seal layer is 0.4~0.9mm.

[0025] The substrate is chamfered and polished to reduce the crystal points on the back and improve the local flatness.

[0026] The substrate is baked at high temperature for a period of time before epitaxy to reduce the self-doping during epitaxy growth. The baking temperature before epitaxy is 1090~1130℃, and the baking time is more than 5min.

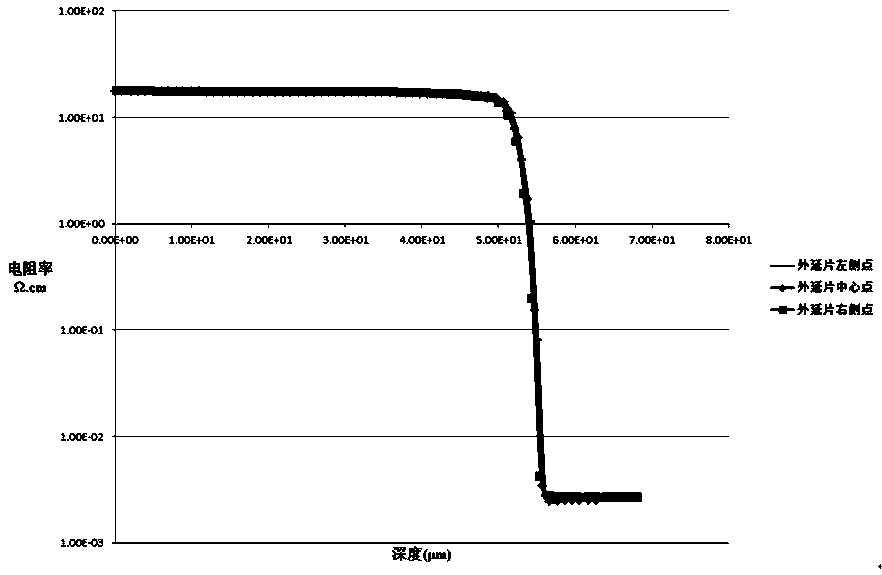

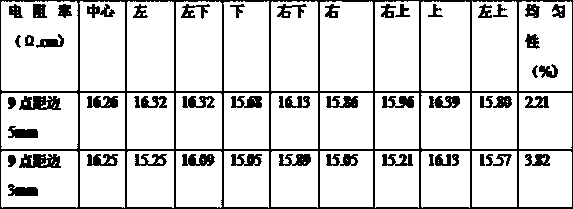

[0027] (2) To grow the first epitaxial layer, grow the first epitaxial layer on the surface of the high-concentration su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com