Double-foot driving non-resonant piezoelectric linear motor and electric excitation method

A linear motor, non-resonant technology, used in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of unsustainable output quantitative preload, reduce motor output Thrust, precision error and other problems, to achieve the effect of convenient integrated processing, guaranteed displacement output, and small processing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

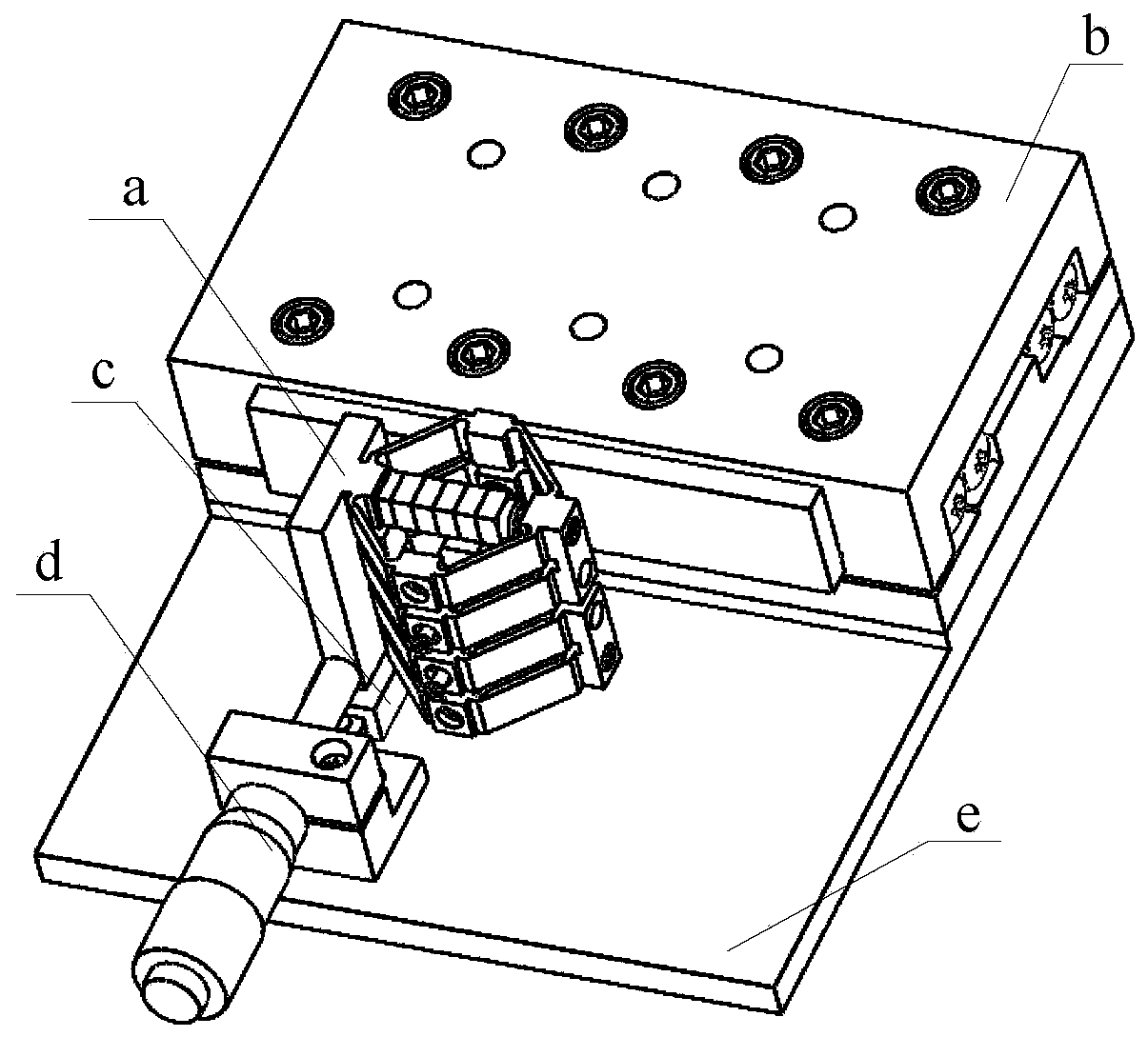

[0036] Such as figure 1 The shown biped-driven non-resonant piezoelectric linear motor includes a stator a, a linear guide b, a ball slide table c, a preload mechanism d and a base e. The base e is arranged horizontally, and the linear guide rail b is horizontally installed on the rear side of the upper end surface of the base e. Both the ball slide table c and the preload mechanism d are installed on the front side of the upper end of the base e, and the ball slide table c is arranged perpendicular to the linear guide rail b. The stator a is fixedly installed on the ball slide table c, and the stator a is located between the linear guide b and the pre-pressure mechanism d, and the stator a is kept in contact with the front end surface of the upper slider of the linear guide b under the pre-pressure of the pre-pressure mechanism d And make the piezoelectric linear motor self-lock when power off.

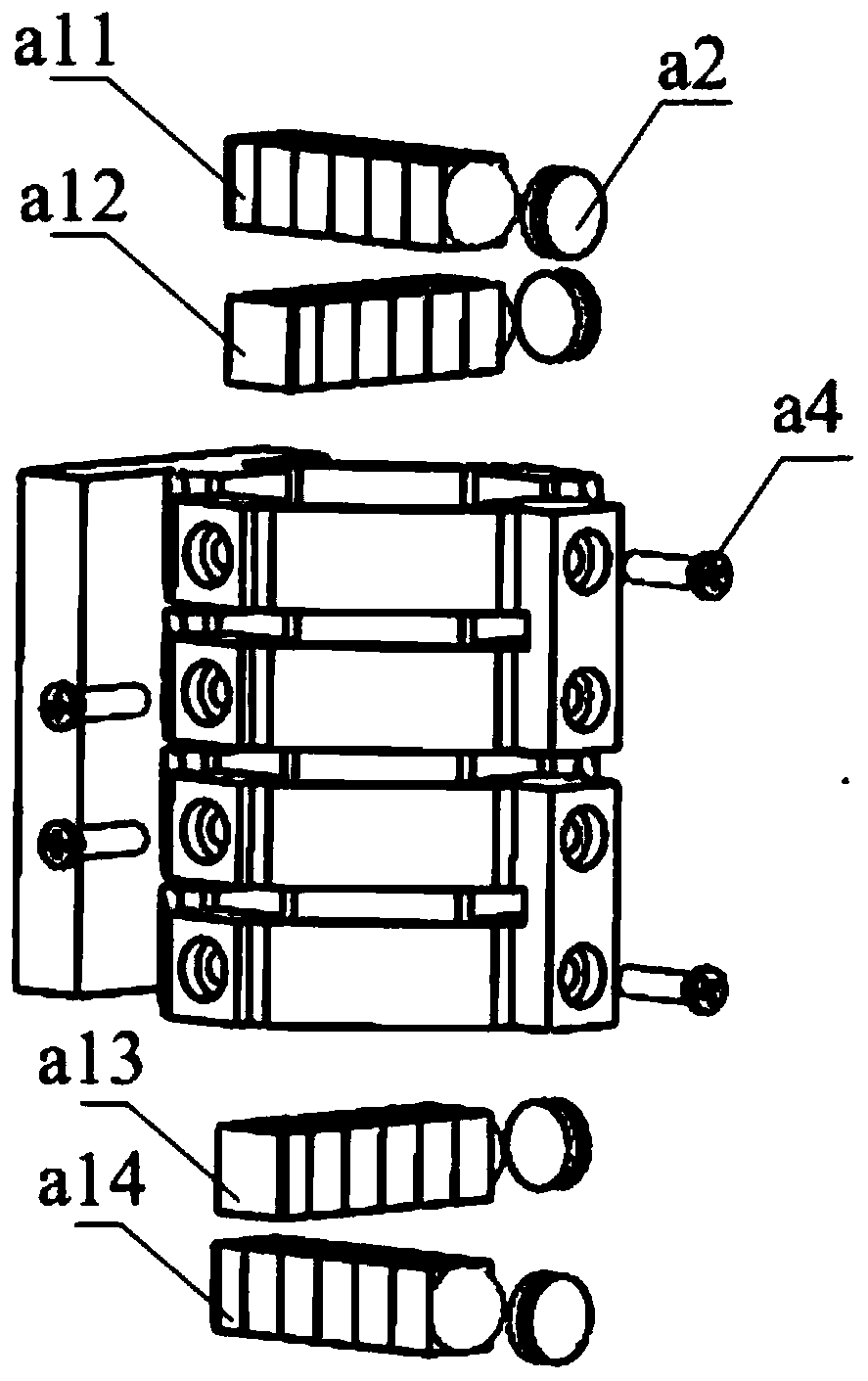

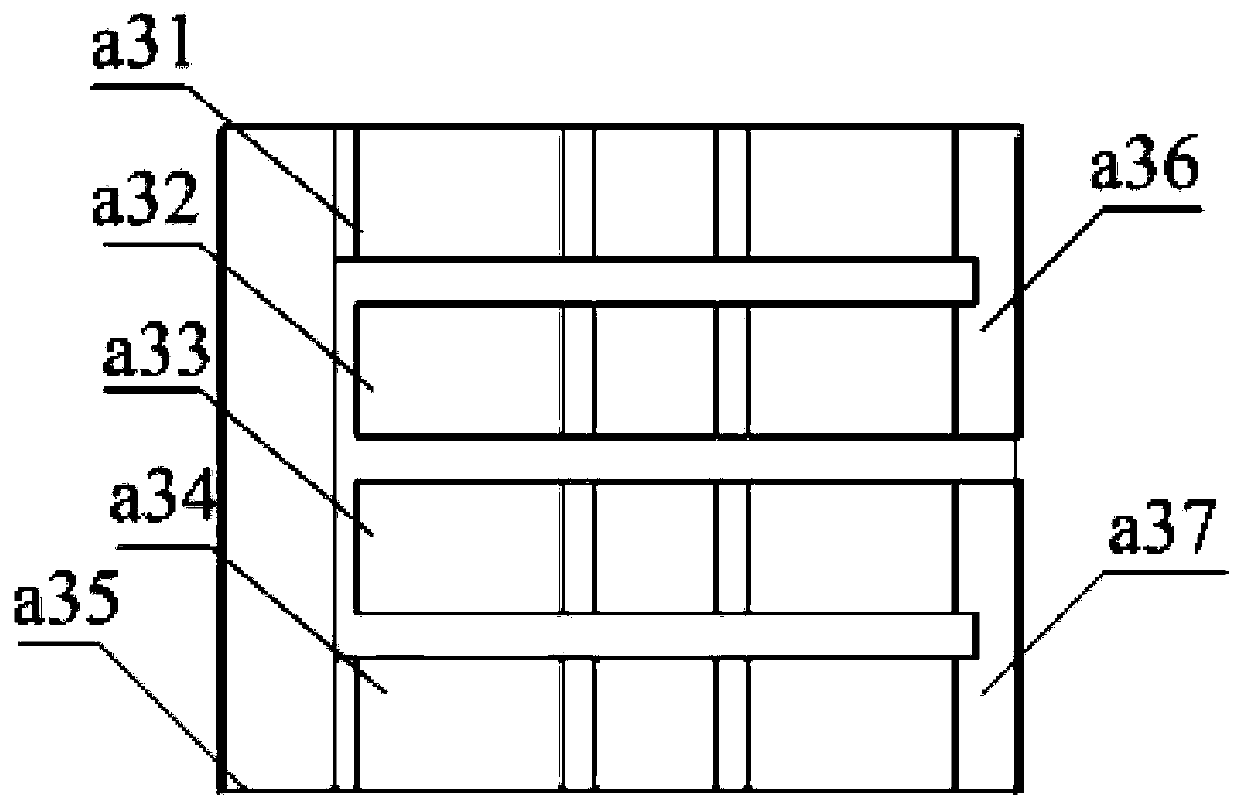

[0037] Specifically, such as Figures 2 to 4 As shown, the stator a includes ...

Embodiment 2

[0050] The second embodiment is basically the same as the first embodiment, except that the directions of the first, second, third and fourth laminated piezoelectric ceramic groups are all parallel to the linear guide rail b.

[0051] An electrical excitation method for biped-driven non-resonant piezoelectric linear motors, see Figure 10 , the excitation method adopted for the four groups of laminated piezoelectric ceramics is: the fourth laminated piezoelectric ceramics group a14 applies a triangular wave voltage signal U with an initial phase of 0 14 ', the third laminated piezoelectric ceramic group a13 applies a square wave voltage signal U with the same frequency and initial phase as the fourth laminated piezoelectric ceramic group a14 13 ', the second laminated piezoelectric ceramic group a12 applies a square wave voltage signal U with the same frequency as the third laminated piezoelectric ceramic group a13 and a phase difference of t / 4 12 ', the first laminated piezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com