Liquid crystalline polyester resin composition and molded article produced therefrom

A technology of polyester resin and liquid crystallinity, which is applied in the field of liquid crystallized polyester resin composition, can solve problems such as poor contact points between terminals and driving obstruction, and achieve excellent sliding properties and improved impact durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

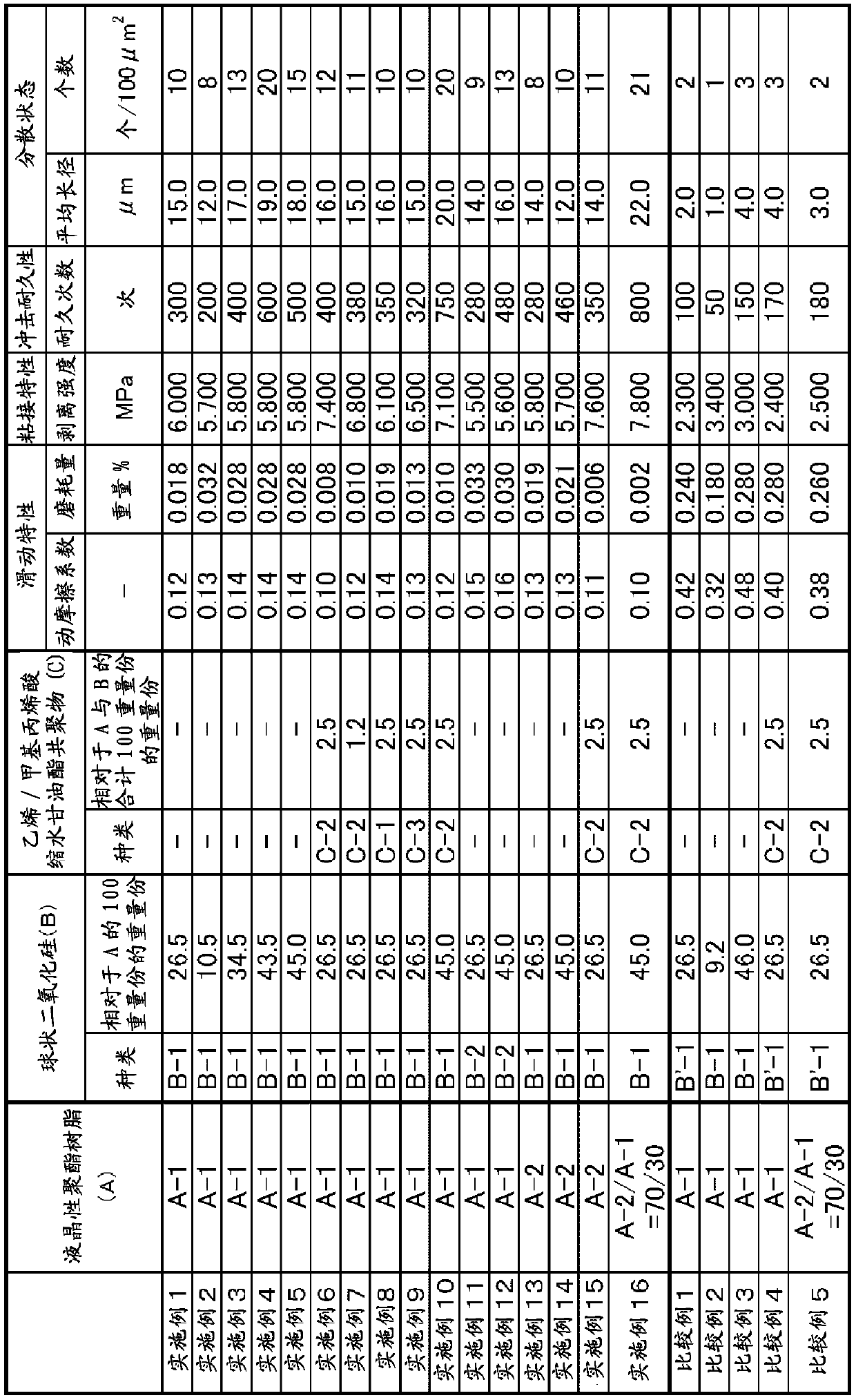

[0083] The effects of the present invention are illustrated below through examples. In addition, % and a part in an Example are all based on weight unless otherwise specified. In addition, the evaluation method of each characteristic shown in an example is as follows.

[0084] [Contact angle of spherical silica]

[0085] Silica was compressed with a tablet maker to form a sheet, and the contact angle of the flat surface of the sheet with respect to water was measured by the method in accordance with JIS R32571999.

[0086] [Sphericity of spherical silica]

[0087] Regarding sphericity, 100 mg of silica was weighed, dispersed in water, and the area and perimeter were measured from the two-dimensional image of 1000 particles optionally extracted using an image processing device (Sysmex Co., Ltd.: FPIA-3000). , calculated from the area and perimeter by the following formula.

[0088] (Sphericity)={4π×(area)÷(circumference) 2}

[0089] [Average particle diameter and particle...

reference example 1

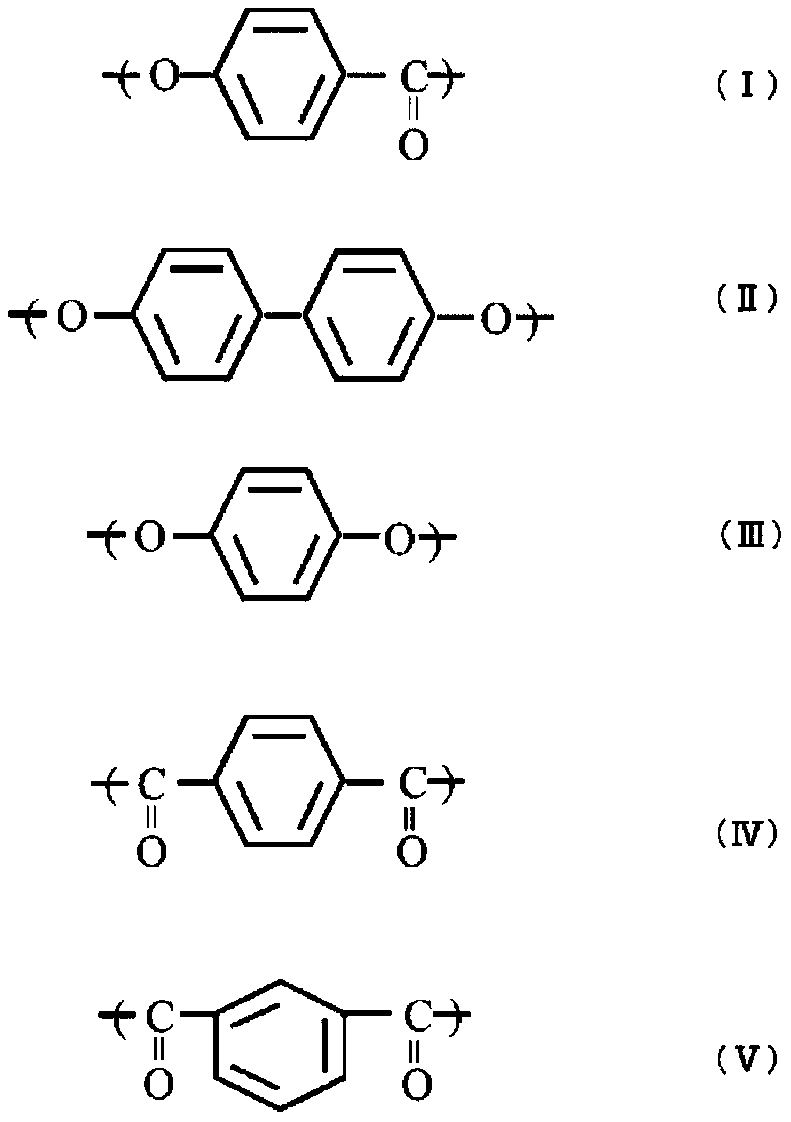

[0102] [Reference Example 1] Synthesis of Liquid Crystalline Polyester Resin (A-1)

[0103] Add 870 parts by weight of p-hydroxybenzoic acid, 327 parts by weight of 4,4'-dihydroxybiphenyl, 89 parts by weight of hydroquinone, 292 parts by weight of terephthalic acid, 157 parts by weight of phthalic acid and 1367 parts by weight of acetic anhydride (1.03 equivalents to the total of phenolic hydroxyl groups) were reacted at 145°C for 2 hours while stirring under a nitrogen atmosphere, and then heated up to 320°C over 4 hours. Then, the polymerization temperature was kept at 320° C., the pressure was reduced to 1.0 mmHg (133 Pa) in 1.0 hour, the reaction was continued for 90 minutes, and the polymerization was completed when the torque required for stirring reached 15 kg·cm. Next, pressurize the reaction vessel to 1.0kg / cm 2 (0.1 MPa), the polymer was discharged into a strand through a die having a circular discharge port with a diameter of 10 mm, and pelletized by a cutter to ob...

reference example 2

[0105] [Reference Example 2] Synthesis of liquid crystalline polyester resin (A-2)

[0106]Add 932 parts by weight of p-hydroxybenzoic acid, 251 parts by weight of 4,4'-dihydroxybiphenyl, 99 parts by weight of hydroquinone, 284 parts by weight of terephthalic acid, 90 parts by weight of phthalic acid and 1252 parts by weight of acetic anhydride (1.09 equivalents of the total phenolic hydroxyl group), reacted at 145°C for 1 hour while stirring under a nitrogen atmosphere, and then increased the jacket temperature from 145°C at an average heating rate of 0.68 °C / min to 270°C, and from 270°C to 350°C at an average temperature increase rate of 1.4°C / min. The heating time is 4 hours. Then, the polymerization temperature was kept at 350° C., the pressure was reduced to 1.0 mmHg (133 Pa) in 1.0 hour, the reaction was continued, and the polymerization was completed when the torque required for stirring reached 10 kg·cm. Next, pressurize the reaction vessel to 1.0kg / cm 2 (0.1 MPa), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com