Yoghourt manufacturing device

A technology for making a device and yogurt, which is applied in the directions of milk preparations, dairy products, and applications, can solve the problems of poor fermentation effect of fresh milk, poor heat preservation effect, and influence on the quality of yogurt, and achieves simple structure, balanced heating, and freshness. good effect of milk fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings.

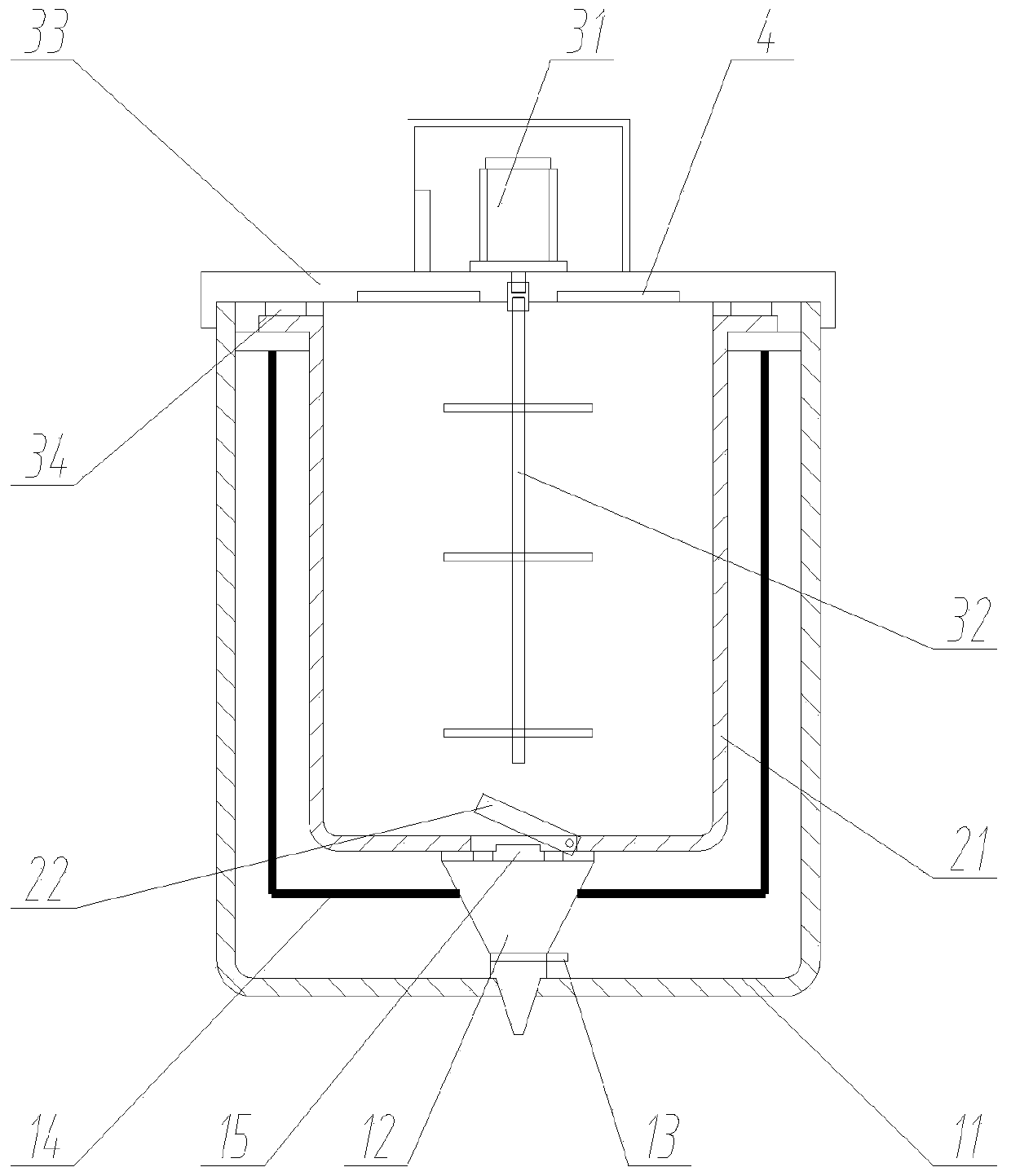

[0017] Such as figure 1 As shown, this yogurt making device includes a shell device and a stirring device;

[0018] The housing device includes an inner housing 21 and an outer housing 11, the lower end of the outer housing 11 is provided with a discharge port 12, the lower end of the discharge port 12 is provided with an electric switch, and the upper end of the discharge port 12 is provided with a stopper 15.

[0019] The inner shell 21 is nested up and down in the outer shell 11, the upper end is closed by a cover 33, and the lower end of the inner shell 21 is provided with a switch board 22 that is rotatably installed, and the stopper 15 can hold the switch board 22 to open it;

[0020] A heating pad 14 is provided between the inner shell 21 and the outer shell 11; the heating pad 14 is connected to the controller, and the controller controls the activation of the heating pad 14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com