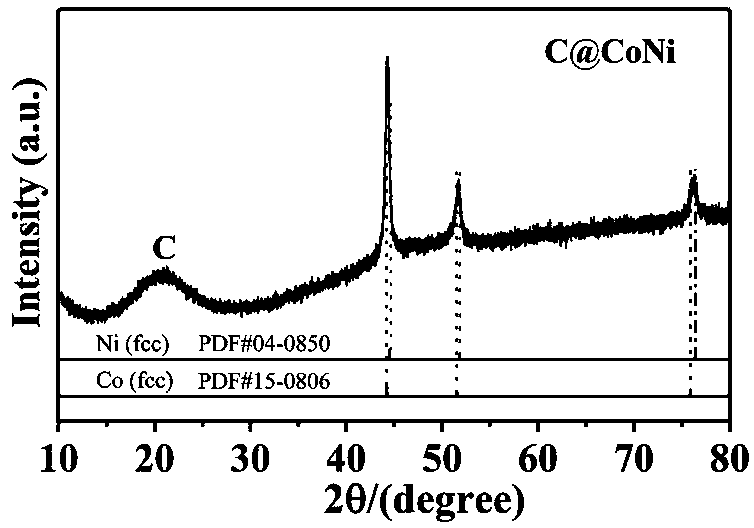

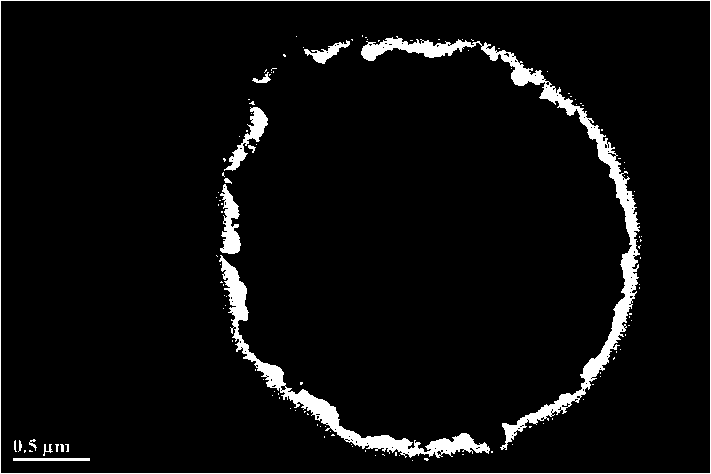

Core-shell structure C@CoNi composite material as well as preparation method and application thereof

A composite material, core-shell structure technology, used in carbon preparation/purification, transportation and packaging, metal processing equipment, etc. The effect of strong absorbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a core-shell structure C@CoNi composite material, comprising the following steps:

[0031] (1) Add 8 g of glucose and 0.2 g of cetyltrimethylammonium bromide (CTAB) into 70 mL of water, and stir well at room temperature;

[0032] (2) Transfer the solution obtained in step (1) to a polytetrafluoroethylene reactor, and set the temperature in a drying oven at 190 °C for hydrothermal reaction for 15 h;

[0033] (3) After the hydrothermal reaction in step (2), the precipitate was taken out, washed three times with distilled water, then washed three times with absolute ethanol, and dried to obtain precursor carbon spheres;

[0034] (4), 6 mmol (0.072 g) carbon spheres, 1 mmol CoCl 2 ·6H 2 O, 1 mmol NiCl 2 ·6H 2 O. Disperse 6 mL of hydrazine hydrate in 60 mL of water and stir evenly at room temperature;

[0035] (5) Transfer the solution obtained in step (4) to a polytetrafluoroethylene reactor, and set the temperature in a drying oven at 170 °C for...

Embodiment 2

[0043] The difference from Example 1 is that the CoCl in step (4) 2 ·6H 2 O and NiCl 2 ·6H 2 The amount of O was changed to 0.5 mmol at the same time, and the obtained product was marked as A-2 sample; others were the same as in Example 1.

Embodiment 3

[0045]The difference from Example 1 is that the CoCl in step (4) 2 ·6H 2 O and NiCl 2 ·6H 2 The amount of O was changed to 0.75 mmol at the same time, and the obtained product was marked as A-3 sample; others were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com