Structure and method for self-flushing oil collecting tank

An oil collecting tank and self-flushing technology, applied in the petroleum industry, hydrocarbon distillation, etc., can solve the problems of inability to talk about good economic benefits of the device, hidden dangers of safety production safety, low heat and mass transfer coefficient, etc., to avoid coking and deposition, Reduced clean-up effort, easy flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] Such as Figure 1~5 As shown, the embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

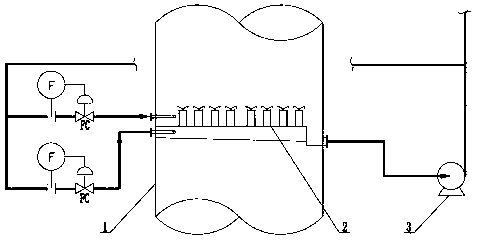

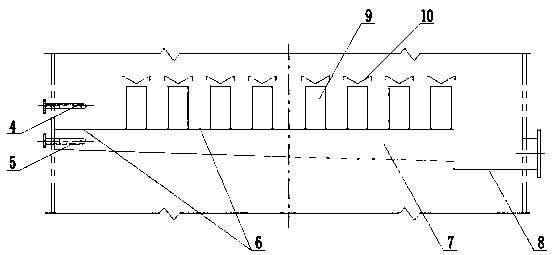

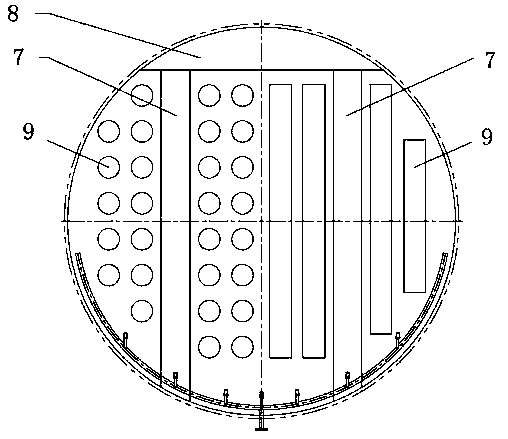

[0029] An oil collection tank self-flushing structure and method thereof, comprising an oil collection tank 2 (composed of an extraction bucket 8, a liquid collection ring and a bottom plate 6, a liquid collection channel 7, Gas riser pipe 9, gas riser cap 10, etc.), the flushing pipeline outside the tower and the circulation pump 3, and the corresponding flushing liquid extraction and flushing liquid return openings on the tower body.

[0030] After the washing oil is extracted from the oil collection tank 2, in addition to being used for process needs, two pipelines are reserved for the oil collection tank 2 to self-flush.

[0031] The oil collecting tank 2 is provided with upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com