Green nontoxic mosquito-proof fabric and preparation method thereof

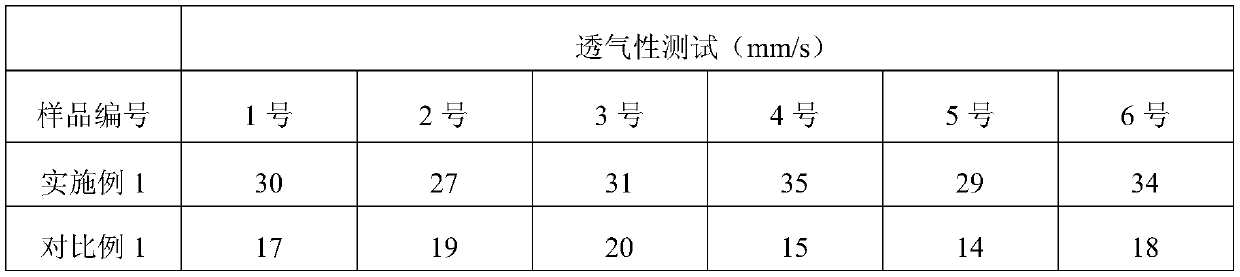

An anti-mosquito and fabric technology, applied in the field of textiles, can solve problems such as impact on wearing performance, user discomfort, poor air permeability, etc., and achieve good anti-mosquito effect, human body safety, and high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

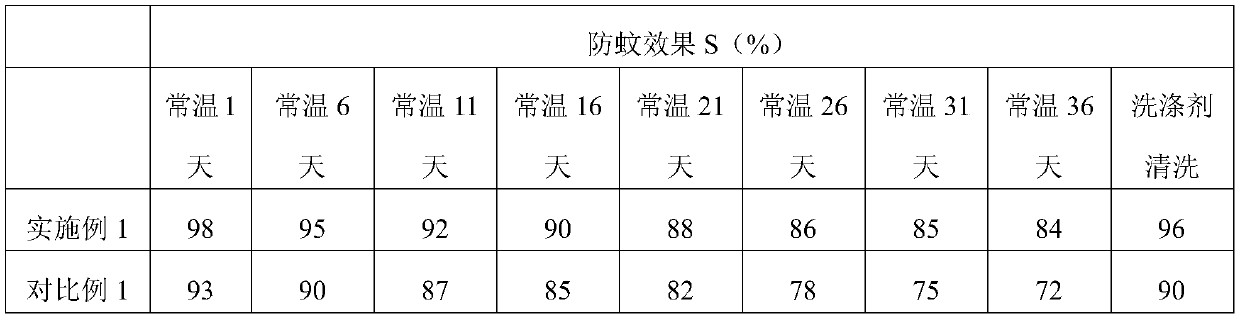

Examples

Embodiment 1

[0032] The green non-toxic anti-mosquito fabric provided by this embodiment is prepared by the following method:

[0033] (1) Preparation of anti-mosquito finishing agent

[0034] Dissolve 15 parts of polyurethane particles in 120 parts of acetone aqueous solution (water temperature 30°C, acetone concentration of 50%), then add 30 parts of p-menthane-3,8-diol and 10 parts of permethrin into the above mixture Stir in the solution evenly, then take 45 parts of plant essential oil extracts and add them to the mixed solution to obtain an anti-mosquito finishing agent, wherein the plant essential oil extracts are lemon eucalyptus essential oil extracts, lavender essential oil extracts, and aloe vera essential oil extracts. According to the combination of mass ratio of 15:15:15.

[0035] (2) Preparation of anti-mosquito fabric

[0036] Cotton fibers and polyester fibers are woven into a fabric body at a mass ratio of 2:3, and then the anti-mosquito finishing agent prepared in step...

Embodiment 2

[0038] The green non-toxic anti-mosquito fabric provided in this example is prepared in the same way as in Example 1, except that β-cyclodextrin is used instead of pyrethroid compounds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com