Construction process of thermal insulation board with truss rib connecting piece

A technology of construction technology and connecting parts, which is applied in the field of construction technology of insulation boards with truss reinforcement connectors, can solve the problems of poor seismic performance of precast concrete sandwich insulation boards, unbalanced temperature deformation, wall structure damage, etc., and achieve reliable Safety and stability, good ductility, and the effect of less wet work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A construction process for insulation panels with truss bar connectors, comprising the following steps:

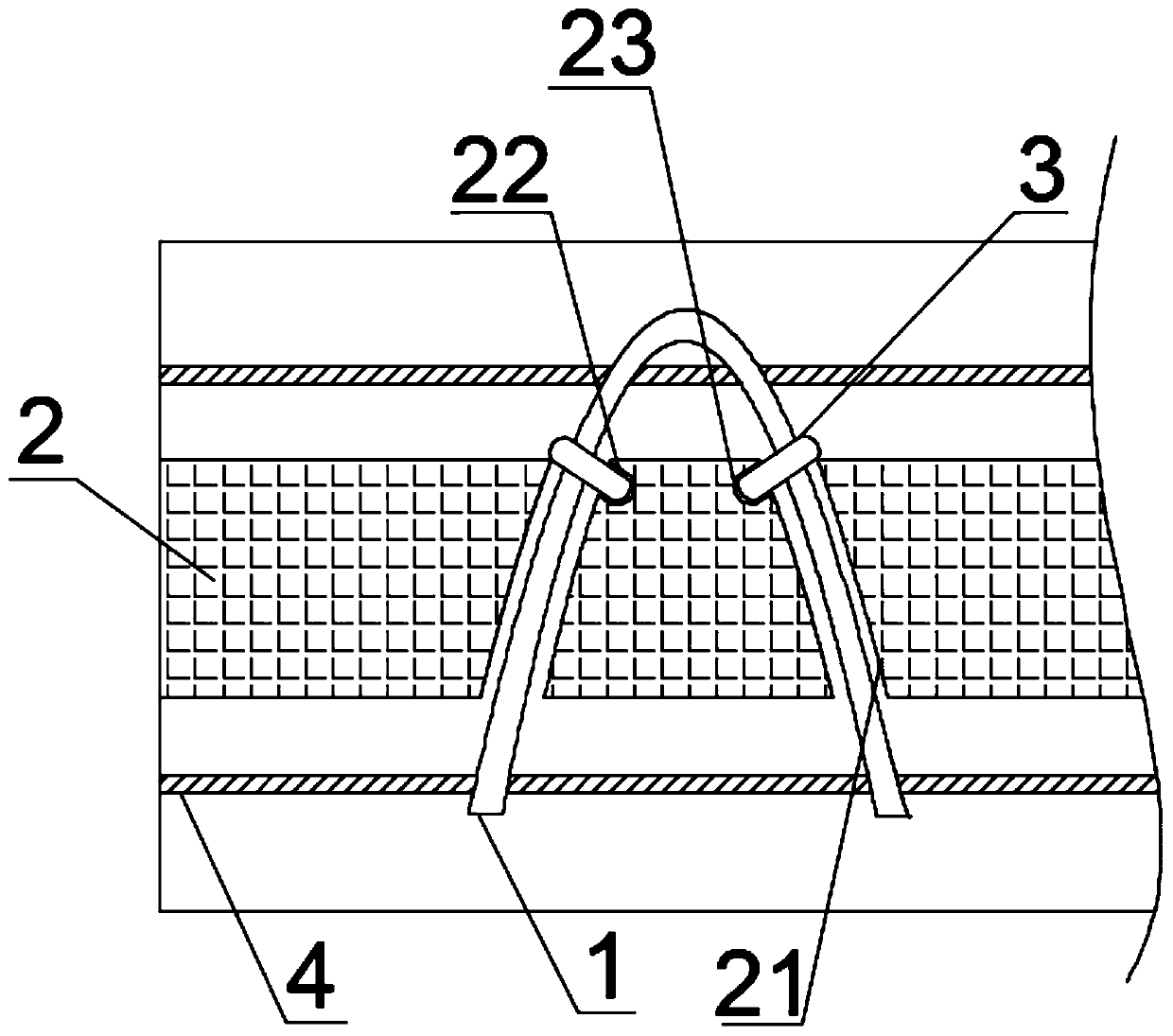

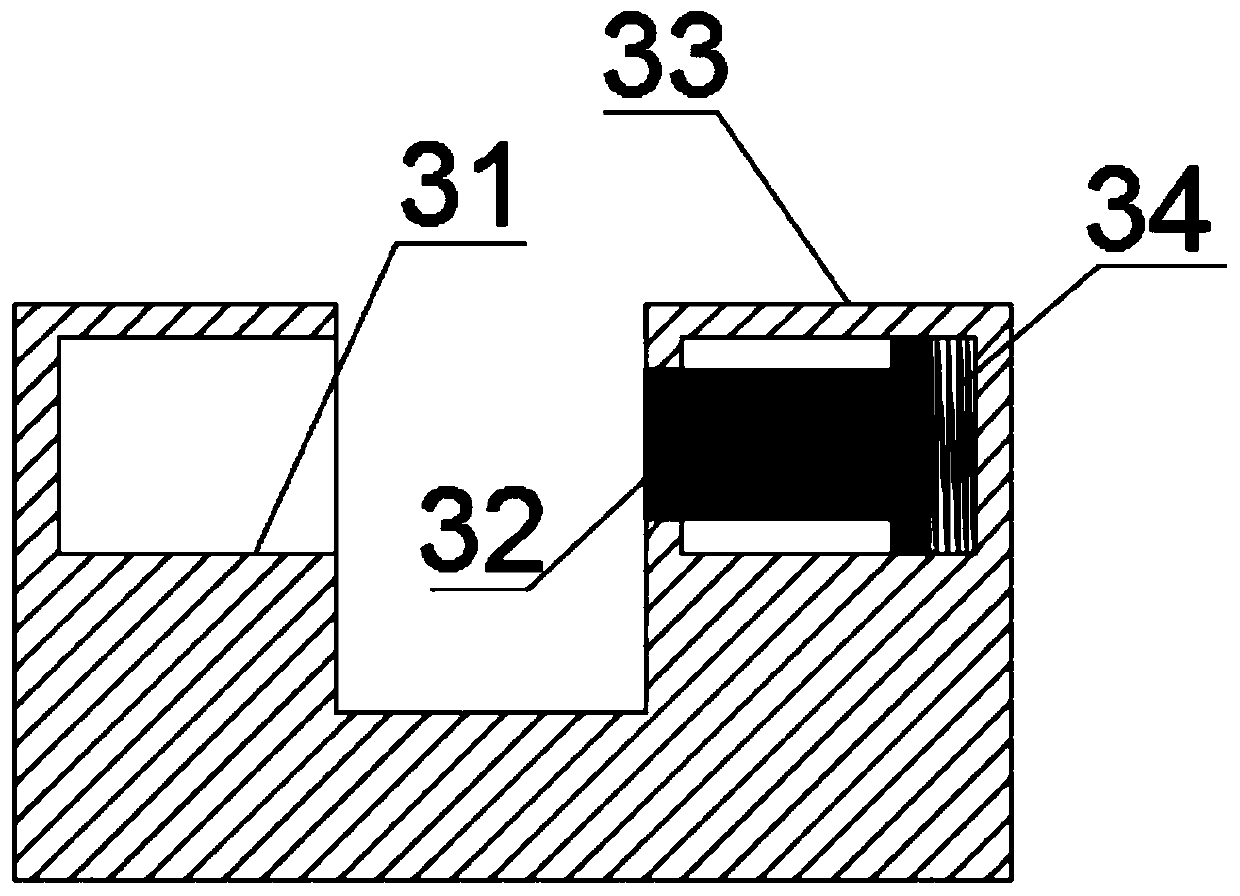

[0025] a) Fixing of connectors: the thickness of the polyurethane board 2 is 70mm, and the polyurethane board 2 is made into a size of 3000mm×1000mm. According to the size of the stainless steel truss bar connector 1, a connecting groove is opened on the polyurethane board 2, and the connecting groove includes the truss bar Groove 21, positioning main groove 22 and positioning auxiliary groove 23, one end of the positioning main groove 22 is connected to the truss rib groove 21, the other end of the positioning main groove 22 is connected to the positioning auxiliary groove 23, and the stainless steel truss tendon connector 1 is inserted into the truss tendon In the groove 21, the distance between the stainless steel truss bar connectors 1 is 600mm, and the stainless steel truss bar connectors 1 are fixed by the positioning ring 3. The positioning ring 3 includes a s...

Embodiment 2

[0029] A construction process for insulation panels with truss bar connectors, comprising the following steps:

[0030] a) Fixing of connectors: the thickness of the polyurethane board 2 is 70mm, and the polyurethane board 2 is made into a size of 3000mm×1000mm. According to the size of the stainless steel truss bar connector 1, a connecting groove is opened on the polyurethane board 2, and the connecting groove includes the truss bar Groove 21, positioning main groove 22 and positioning auxiliary groove 23, one end of the positioning main groove 22 is connected to the truss rib groove 21, the other end of the positioning main groove 22 is connected to the positioning auxiliary groove 23, and the stainless steel truss tendon connector 1 is inserted into the truss tendon In the groove 21, the distance between the stainless steel truss bar connectors 1 is 600mm, and the stainless steel truss bar connectors 1 are fixed by the positioning ring 3. The positioning ring 3 includes a s...

Embodiment 3

[0034] A construction process for insulation panels with truss bar connectors, comprising the following steps:

[0035] a) Fixing of connectors: The thickness of the polyurethane board 2 is 90mm, and the polyurethane board 2 is made into a size of 3000mm×1000mm. According to the size of the stainless steel truss bar connector 1, a connecting groove is opened on the polyurethane board 2, and the connecting groove includes the truss bar Groove 21, positioning main groove 22 and positioning auxiliary groove 23, one end of the positioning main groove 22 is connected to the truss rib groove 21, the other end of the positioning main groove 22 is connected to the positioning auxiliary groove 23, and the stainless steel truss tendon connector 1 is inserted into the truss tendon In the groove 21, the distance between the stainless steel truss bar connectors 1 is 600mm, and the stainless steel truss bar connectors 1 are fixed by the positioning ring 3. The positioning ring 3 includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com