Closed loop grouting assembly, robot system and grouting method capable of achieving automatic control

A robotic system and closed-loop technology, which is applied to the processing of building components, building reinforcements, and building materials, can solve problems such as low grouting quality and efficiency, high requirements for construction workers' engineering experience, and poor working environment, etc., to improve The degree of automation and intelligence, the effect of ensuring stability and controllability, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

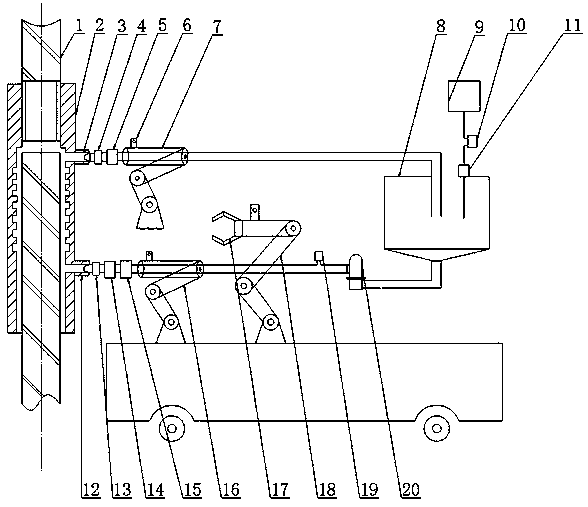

[0037] Such as figure 1 As shown, an automatically controlled closed loop grouting assembly, including a steel sleeve 2 and a grouting pipe, to figure 1 Take the direction as an example, the steel bar sleeve 2 is sleeved on the outer circumference of the steel bar 1, and the two are coaxially arranged, wherein, the steel bar sleeve 2 is provided with a slurry outlet 3 and a slurry inlet 12 from top to bottom, and the slurry outlet 3 and the inlet The grout opening 12 can be respectively provided with one, also can be provided with several, constitutes the grouting opening jointly. Wherein, the grout outlet 3 and the grout inlet 12 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com