Unidirectional tensile high-temperature mechanical property test system and method for sheet material

A uniaxial tensile, high temperature mechanics technology, applied in the direction of analyzing materials, scientific instruments, strength properties, etc., can solve the problem of inability to accurately obtain the strain field of the specimen, and achieve fast heating speed, rapid and uniform heating, and good temperature uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

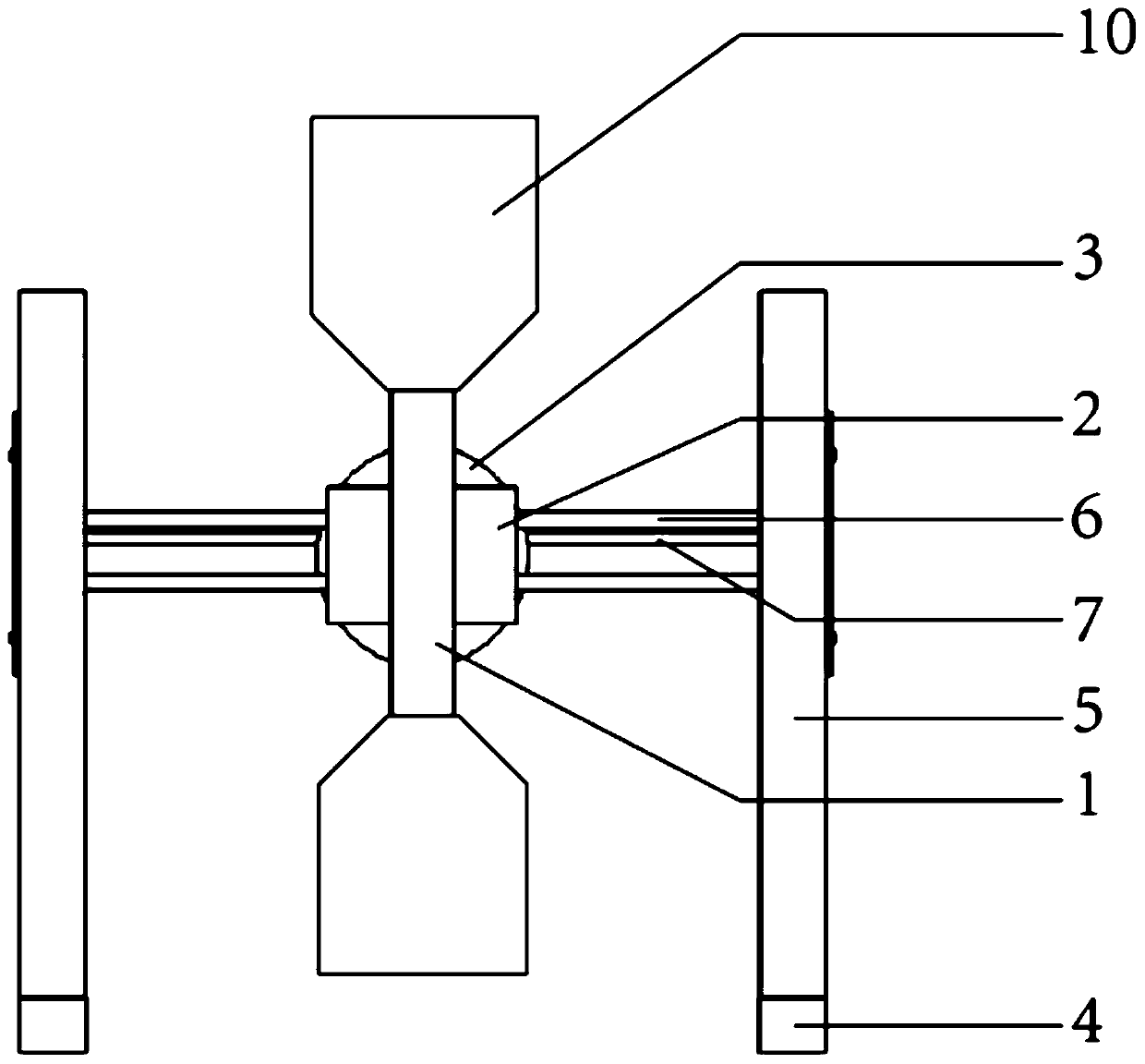

[0028] This embodiment provides a uniaxial tensile high-temperature mechanical performance test system for a plate, including a tensile test device and two heating devices symmetrically arranged on the tensile test device.

[0029] Please refer to the attached figure 1 , the tensile test device includes a workbench, two clamps 10 arranged on the workbench and a tensile test piece 1 clamped between the two clamps.

[0030] Two heating devices are symmetrically arranged on the workbench, located on both sides of the tensile test piece. Specifically, the heating device includes a PLC control system, an induction heating power supply, an induction coil 3, an iron plate 2 and an iron plate support frame.

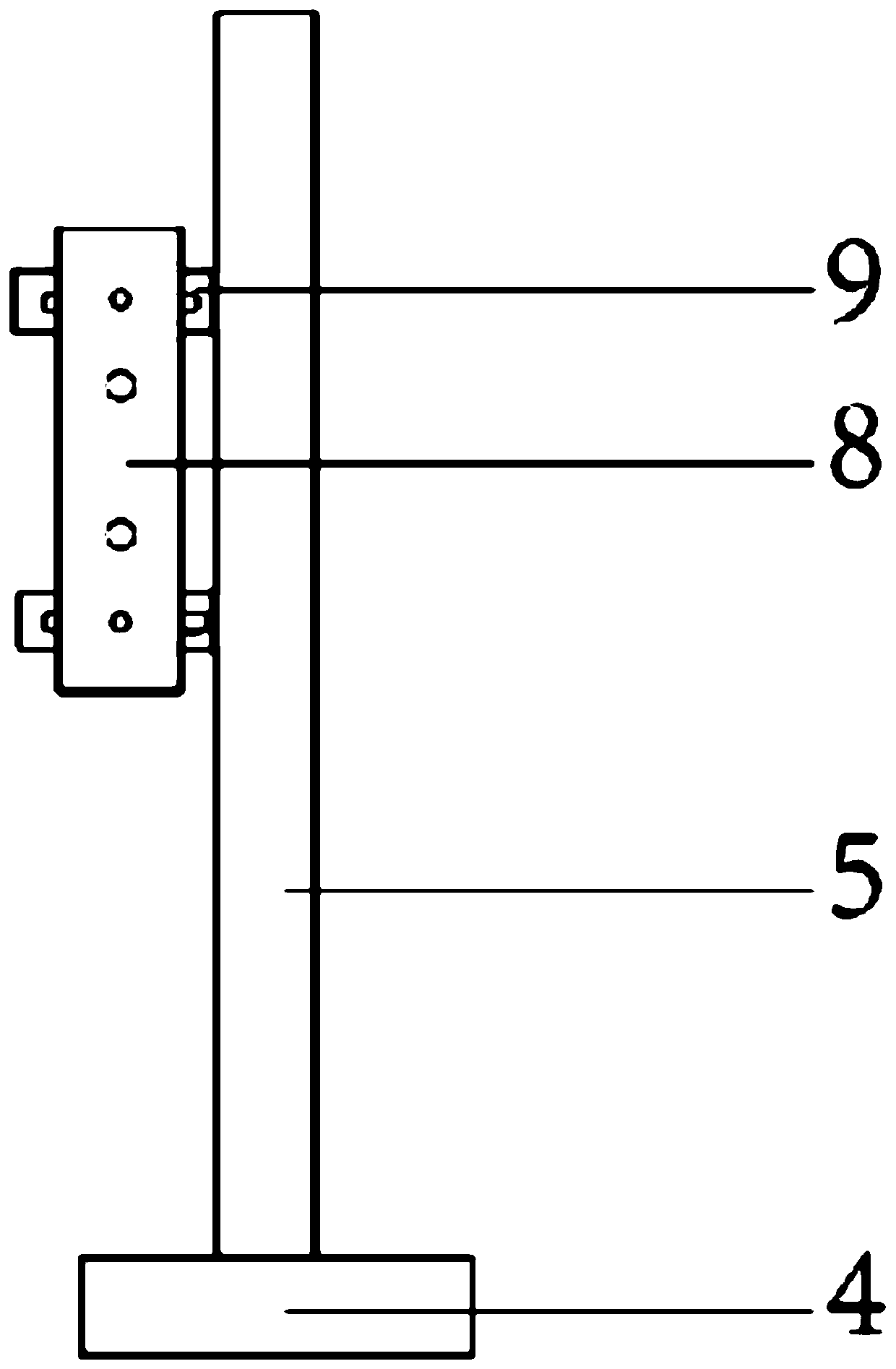

[0031] The iron support frame is arranged on the workbench of the tensile test device. Please refer to the attached figure 1 , the iron plate support frame includes a base 4 and a support column 5 arranged on the base, the iron plate 2 is fixed on the support column 5 by two s...

Embodiment 2

[0039] This embodiment provides a test method for uniaxial tensile high-temperature mechanical properties of plates, which is implemented based on the test system for uniaxial tensile high-temperature mechanical properties of plates described in Embodiment 1. The method includes the following steps:

[0040] S101, the induction heating power supply outputs current to the induction coil, the iron plate is heated by the induction coil, and the heat is transferred to the tensile test piece to realize rapid and uniform heating of the tensile test piece.

[0041] S102, the thermocouple wire collects the temperature of the tensile test piece, and transmits it to the thermocouple module.

[0042] S103, the thermocouple module acquires the specimen temperature collected by the thermocouple wire, and transmits it to the CPU processor module, and the CPU processor module processes the specimen temperature data collected by the thermocouple wire, and transmits it to the PLC controller;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com