Engine test bench water temperature control system

A test bench and water temperature control technology, applied in control/regulation systems, temperature control, non-electric variable control, etc., can solve the problems of low service life of resistance heaters, lagging equipment control temperature, and affecting the efficiency of rapid heat engines, etc. Achieve the effects of eliminating water temperature control fluctuations, low maintenance costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

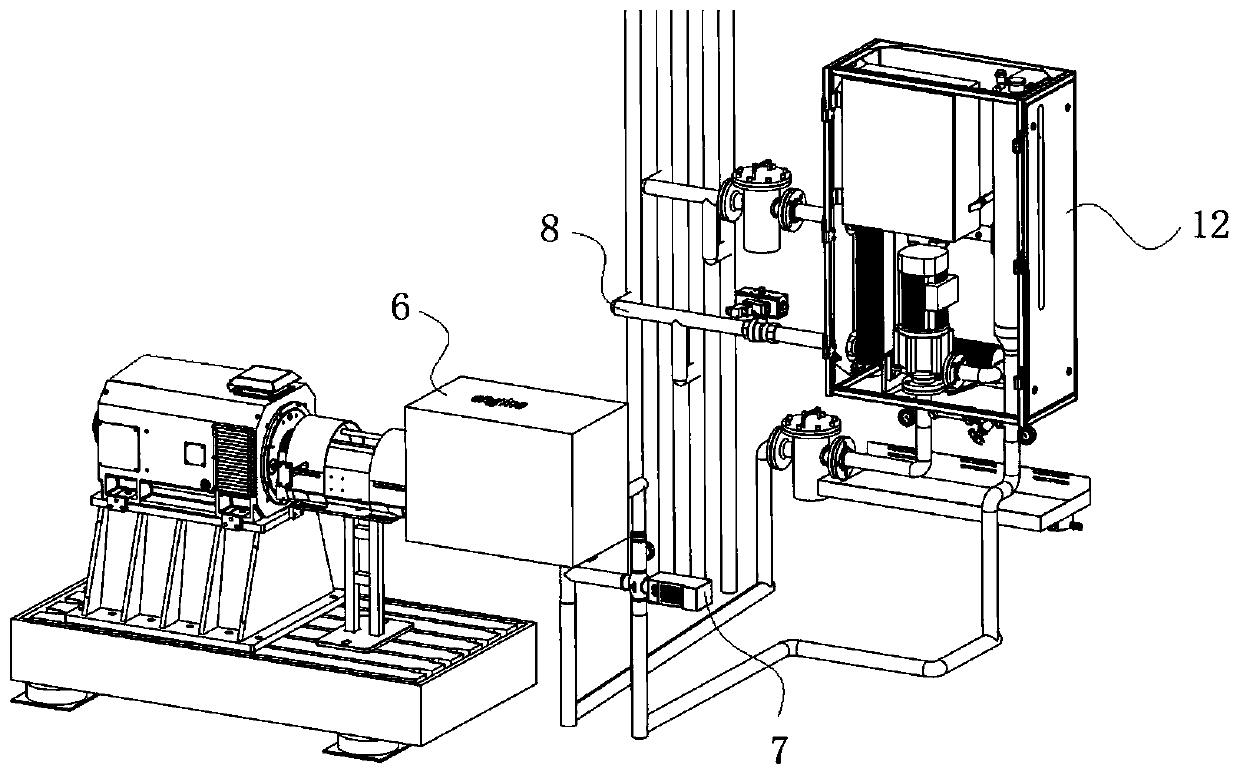

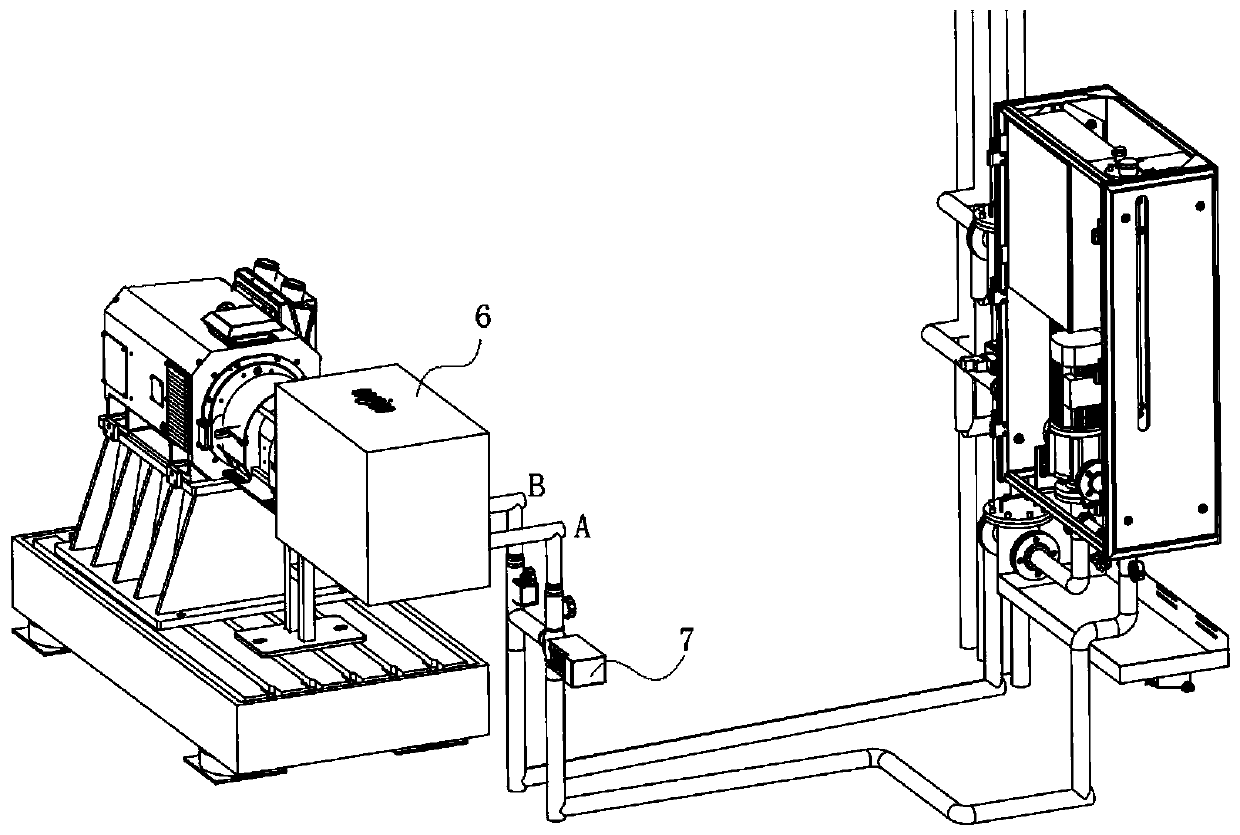

[0032] Such as figure 1 , 2 , 4, the present embodiment provides a water temperature control system for an engine test bench, including PLC1, a circulation loop and a fixed cabinet 12, the circulation loop includes a water pump 2, a heating device 3, a heat exchanger 4, and a liquid replenishment pipe 5, The water pump 2, the heating device 3, the heat exchanger 4, and the liquid replenishment pipe 5 are sequentially connected to each other, and the PLC 1 is electrically connected to all components of the circulation loop and controlled centrally.

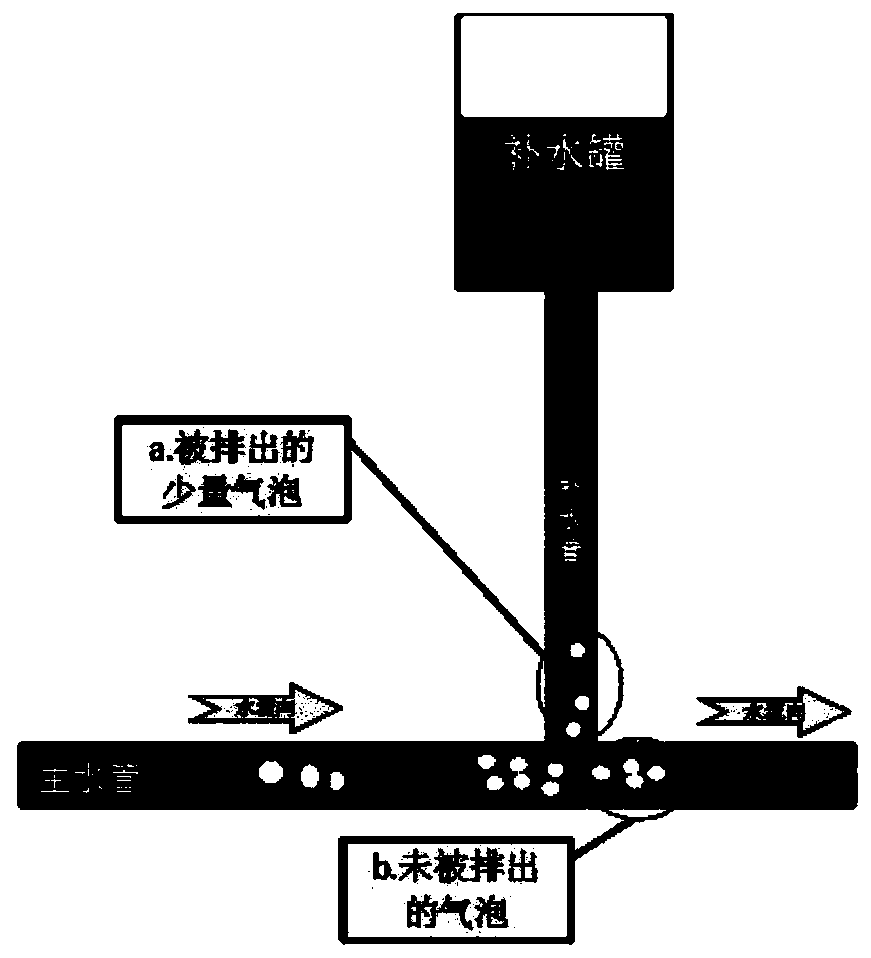

[0033] Specifically, the water pump 2 is used to increase the water pressure and promote the circulation of the water flow; the heating device 3 is used to heat the water flow; the heat exchanger 4 is used to supplement cold water and assist the temperature change of the water flow; the liquid replenishment pipe 5 is used to discharge the water flow Air bubbles in the tank, and replenish the engine 6 liquid level loss, directly t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com