Small-caliber pipeline dense mesh welding argon filling device and method

A technology of dense mesh and small diameter, which is applied in the field of argon filling device for dense mesh welding of small diameter pipes, which can solve the problems of limited use times of argon filling tools, uneven gas output of argon filling tools, partial blowing of argon gas and shock arc, etc. Achieve the effect of convenient and fast production, simple structure and guaranteed welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

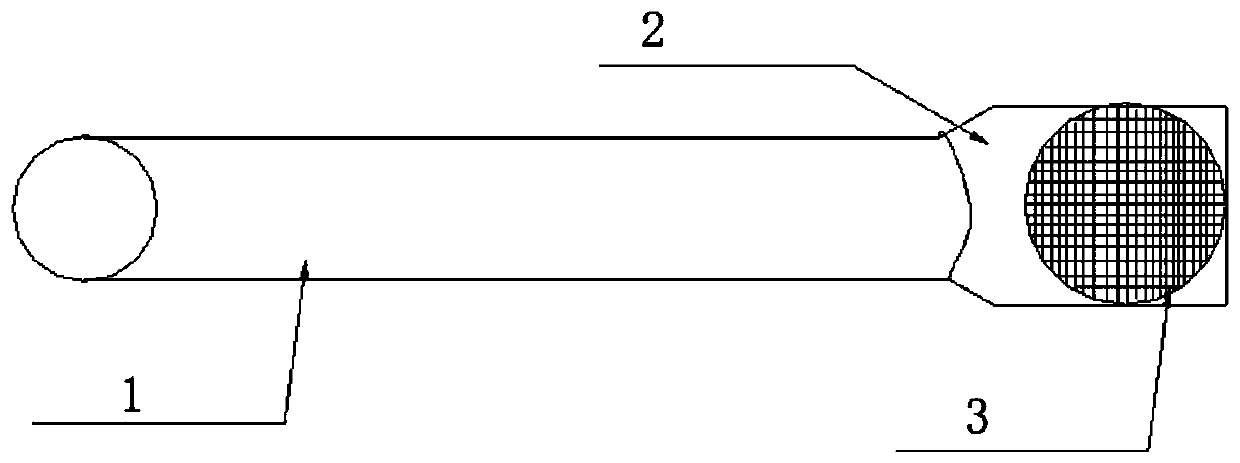

[0035] Attached below figure 1 The argon charging device disclosed in this embodiment is further described;

[0036] Refer to attached figure 1 As shown, the argon charging device for small-caliber pipeline dense-mesh welding includes a pipe fitting 1, which is a hollow pipe.

[0037] One end of the pipe fitting 1 is provided with a flat member, and the pipe fitting 1 communicates with the flat member. The flat member includes two oppositely arranged plates 2. , the connection between the two plates and the pipe is a closed structure.

[0038] The two boards 2 are provided with through holes, and the through holes of the two boards 2 are arranged oppositely, and the through holes 2 of the two boards are all provided with a dense mesh 3 . The opening direction of the through hole is perpendicular to the axial direction of the pipe fitting 1 . The diameter of the through hole is slightly smaller than the width of the plate 2 .

[0039] In this embodiment, the pipe part 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com