Stirring head with stirring needle with concave rotation contour

The technology of stirring needle and stirring head is applied in the field of friction stir welding, which can solve the problems of insufficient flow of softened material in the welding seam area, bad influence on the quality of welding seam, insufficient stirring and forging pressure, etc., and achieves simple and reliable structure, reduced volume, and increased The effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

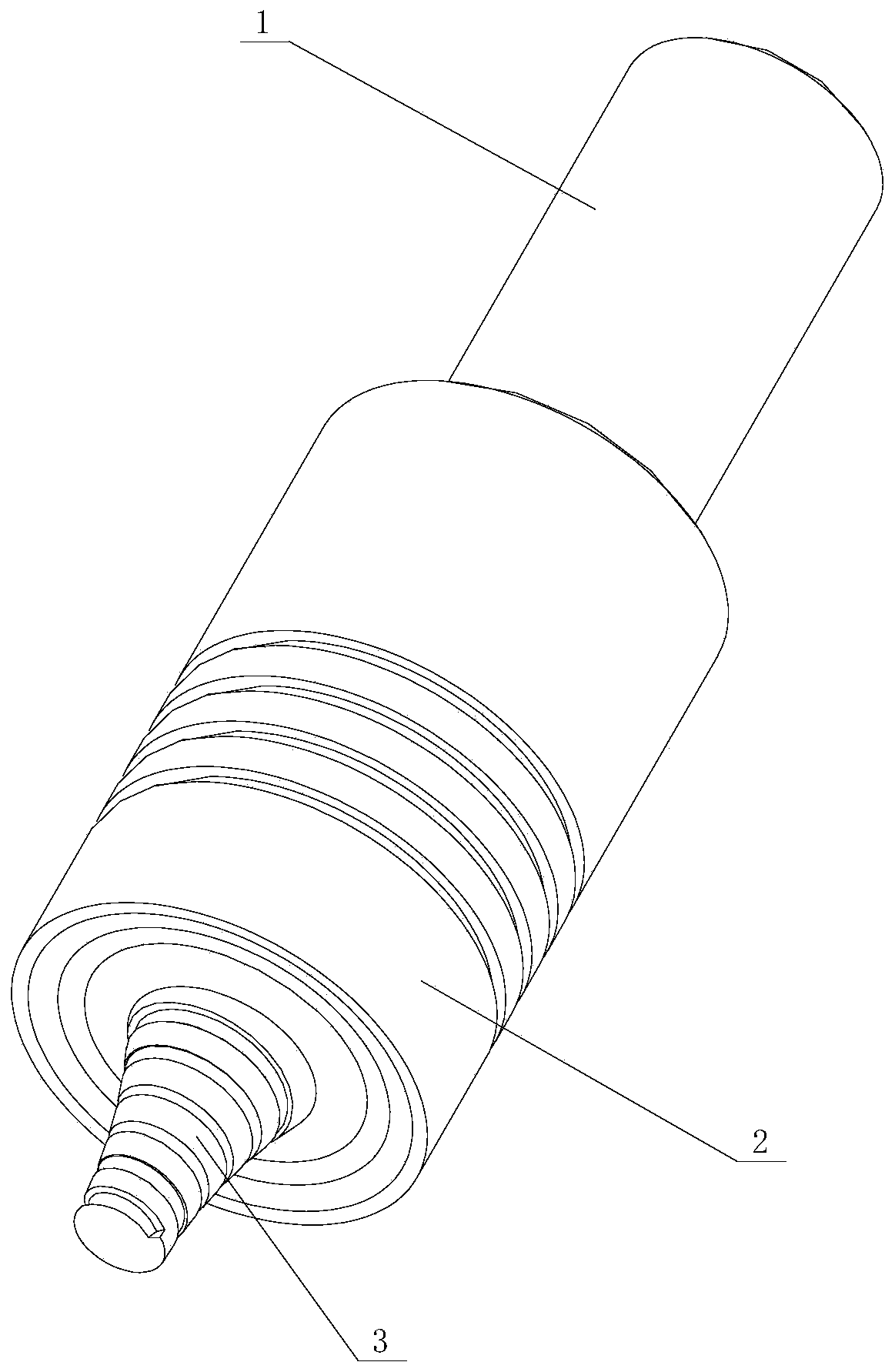

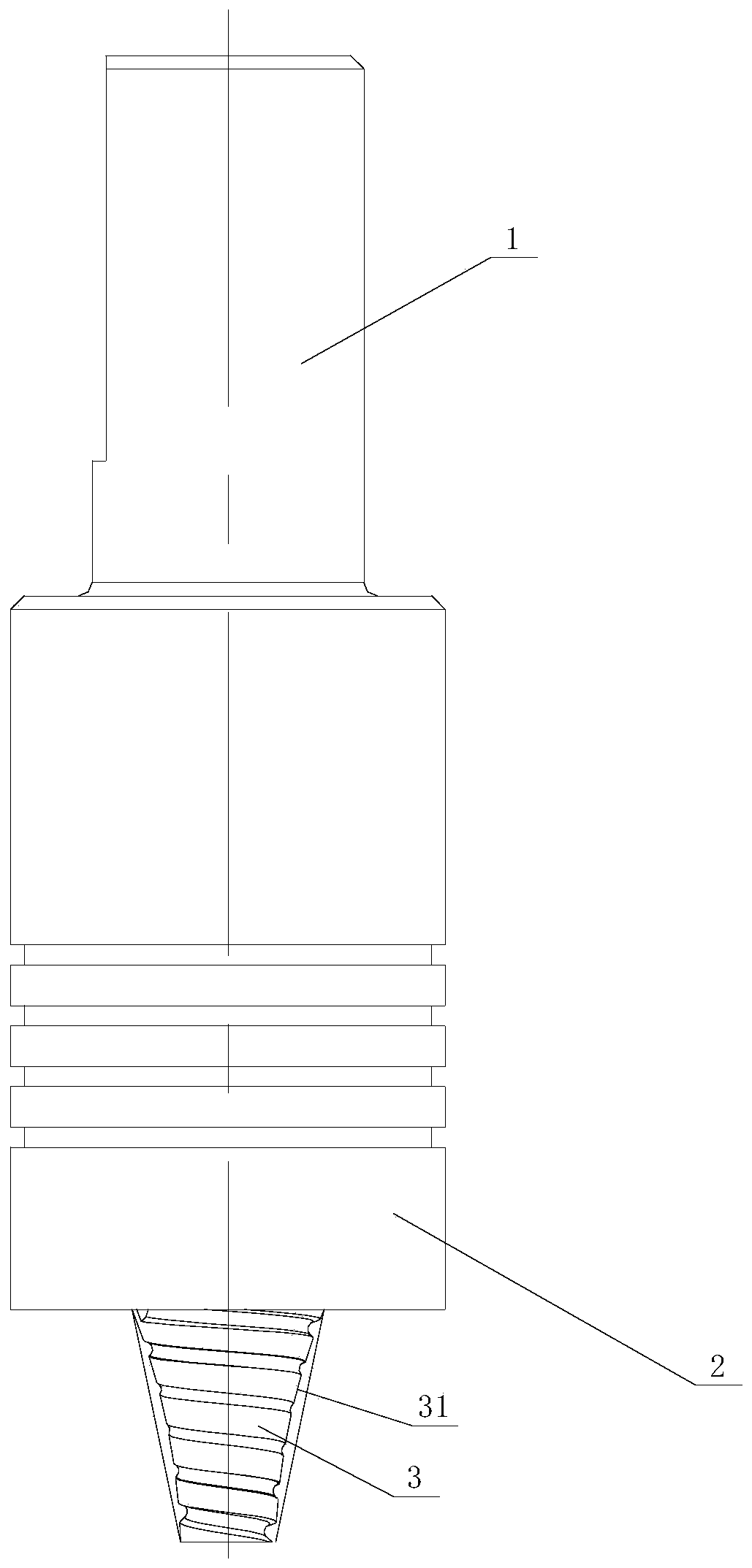

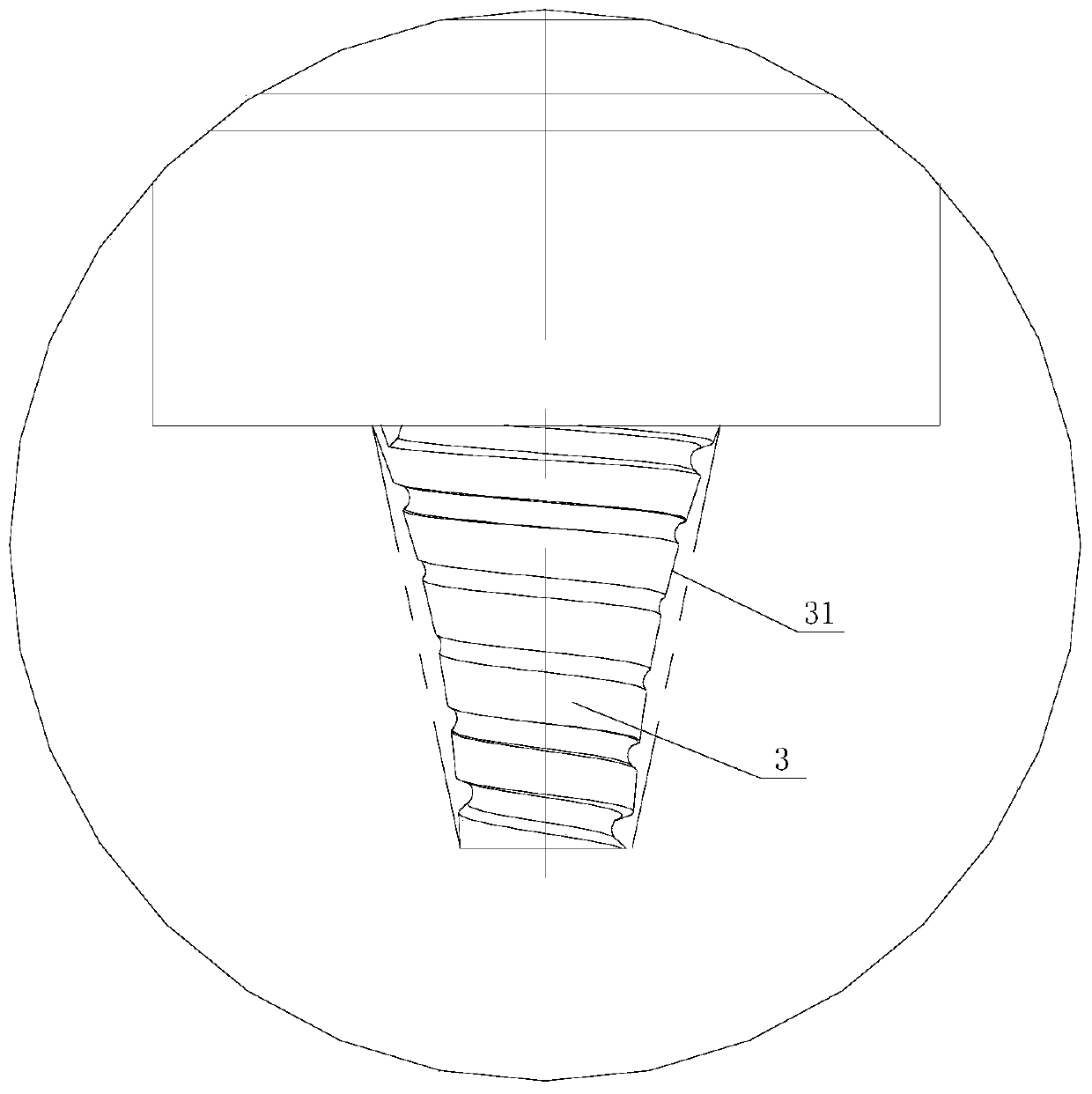

[0035] Figure 1 to Figure 4 It shows the first embodiment of the stirring head of the present invention, which is concave in the rotation profile of the stirring needle, including the clamping part 1, the shaft shoulder part 2 and the stirring needle 3 connected in sequence, and the peripheral side of the stirring needle 3 is provided with a Recess 31 for forging pressure. During welding, the clamping part 1 is used for clamping, the stirring pin 3 generates heat energy through rotational friction, and the shoulder part 2 is used to form forging. Compared with the traditional structure, the stirring head is provided with a concave portion 31 on the peripheral side of the stirring needle 3, that is, the peripheral side of the stirring needle 3 is concave, which increases the forging force in the inner depth direction, thereby increasing the density of the weld seam It is beneficial to increase the strength of the weld seam and improve the quality of the weld seam; at the same...

Embodiment 2

[0041] Such as Figure 5 As shown, the second embodiment of the concave stirring head with the rotation profile of the stirring needle of the present invention is basically the same as that of Embodiment 1, the only difference is that in this embodiment, the outer contour of the concave portion 31 is formed by multiple inner sections Concave arc lines are connected to form. In this structure, the peripheral outline of the concave portion 31 is composed of multiple curves, and the structure is simple and reliable.

Embodiment 3

[0043] Such as Figure 6 As shown, the third embodiment of the stirring head of the present invention with a concave shape of the stirring needle rotation profile, the stirring head is basically the same as that of Embodiment 1, the only difference is that in this embodiment, the peripheral contour of the concave portion 31 is concave The circular arc lines and oblique lines are connected. In this structure, the peripheral outline of the concave portion 31 is composed of a combination of curved and oblique lines, and the structure is simple and reliable.

[0044] In this embodiment, the arc line is close to the needle base 34 , and the oblique line is close to the needle tip 33 . Its structure is simple and easy to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com