Broadband laser processing optical system capable of being modulated and processing method

A laser processing and optical system technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as low efficiency and poor processing quality, and achieve the effect of improving flexibility, improving processing quality, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

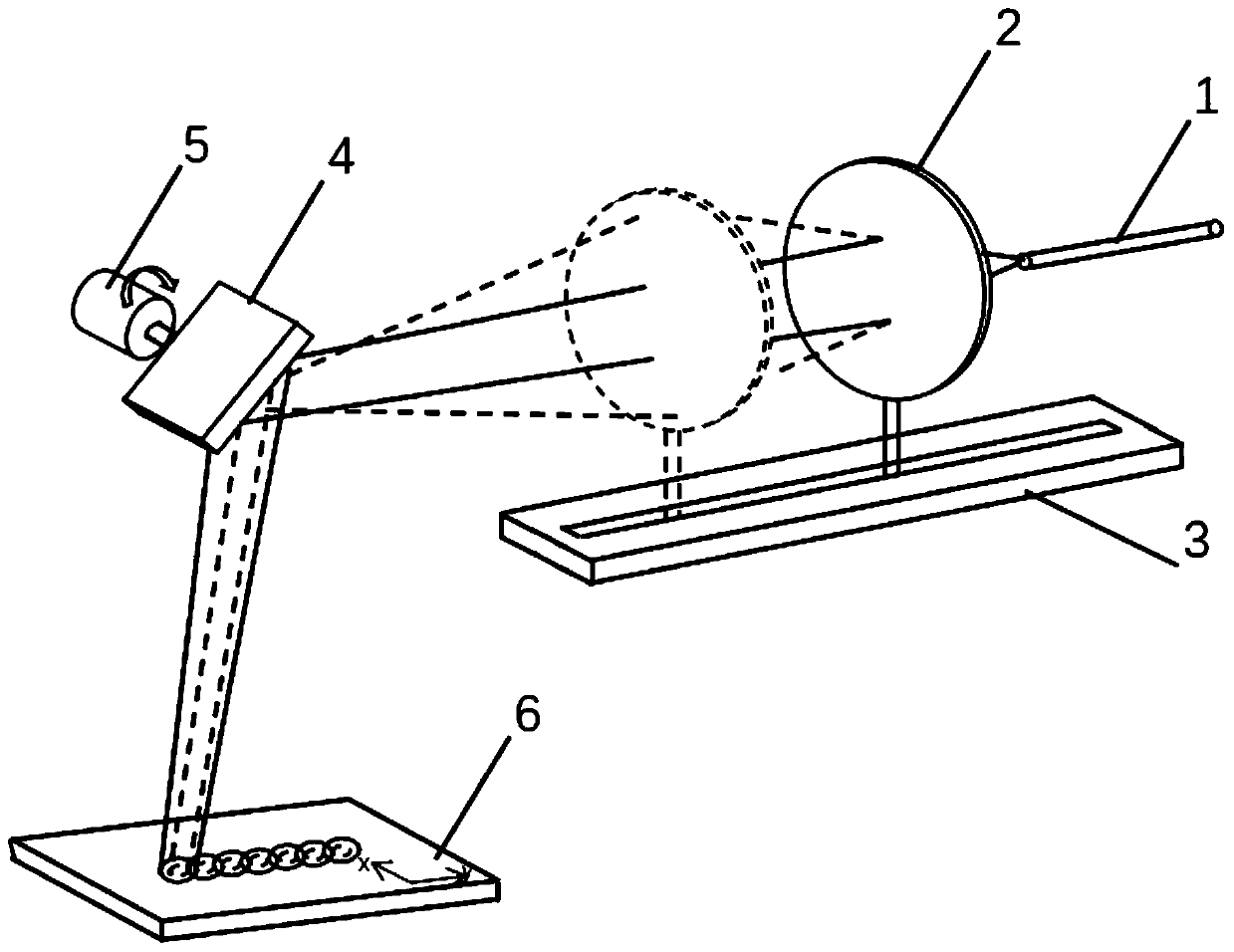

Embodiment 1

[0030] Such as figure 1 As shown, an adjustable broadband laser processing optical system provided by the embodiment of the present invention includes a fiber laser 1, a focusing lens 2, a first motor and a guide rail 3 for controlling the movement of the focusing lens 2, a vibrating mirror 4, and a driving vibrator. The second motor 5 and the working surface 6 of the mirror vibration. The beam emitted by the fiber laser 1 enters the focusing lens 2 at a certain divergence angle, and the beam is collimated and focused by the focusing lens 2 and then enters the vibrating mirror 4, and then is reflected to the working surface 6 by the vibrating mirror 4.

[0031] The focusing lens 2 is connected with the bracket on the guide rail, and is controlled by the first motor to move back and forth along the optical axis direction on the guide rail, so as to realize the effect of changing spots on the working surface 6 . The traditional laser processing optical system uses a combination...

Embodiment 2

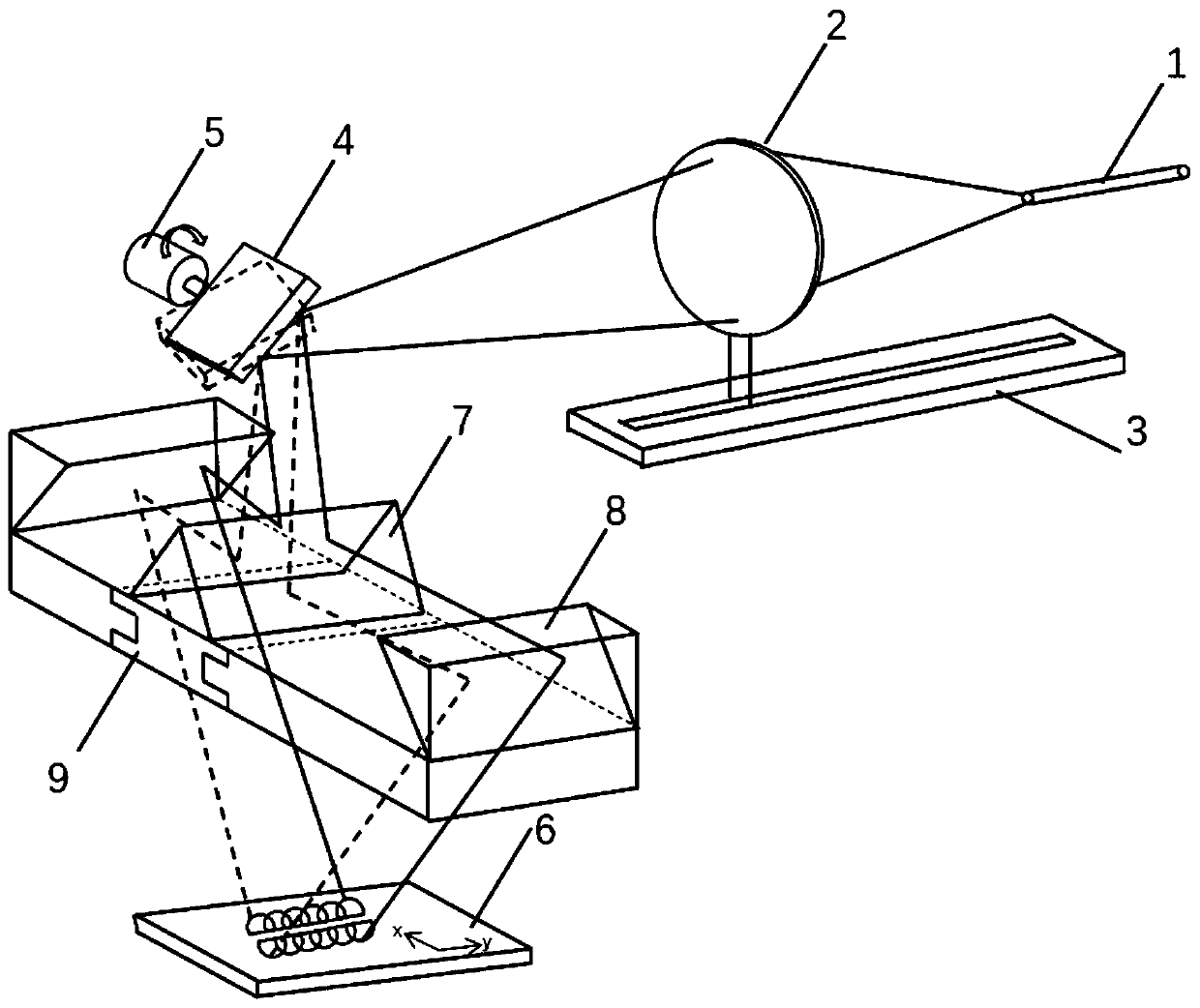

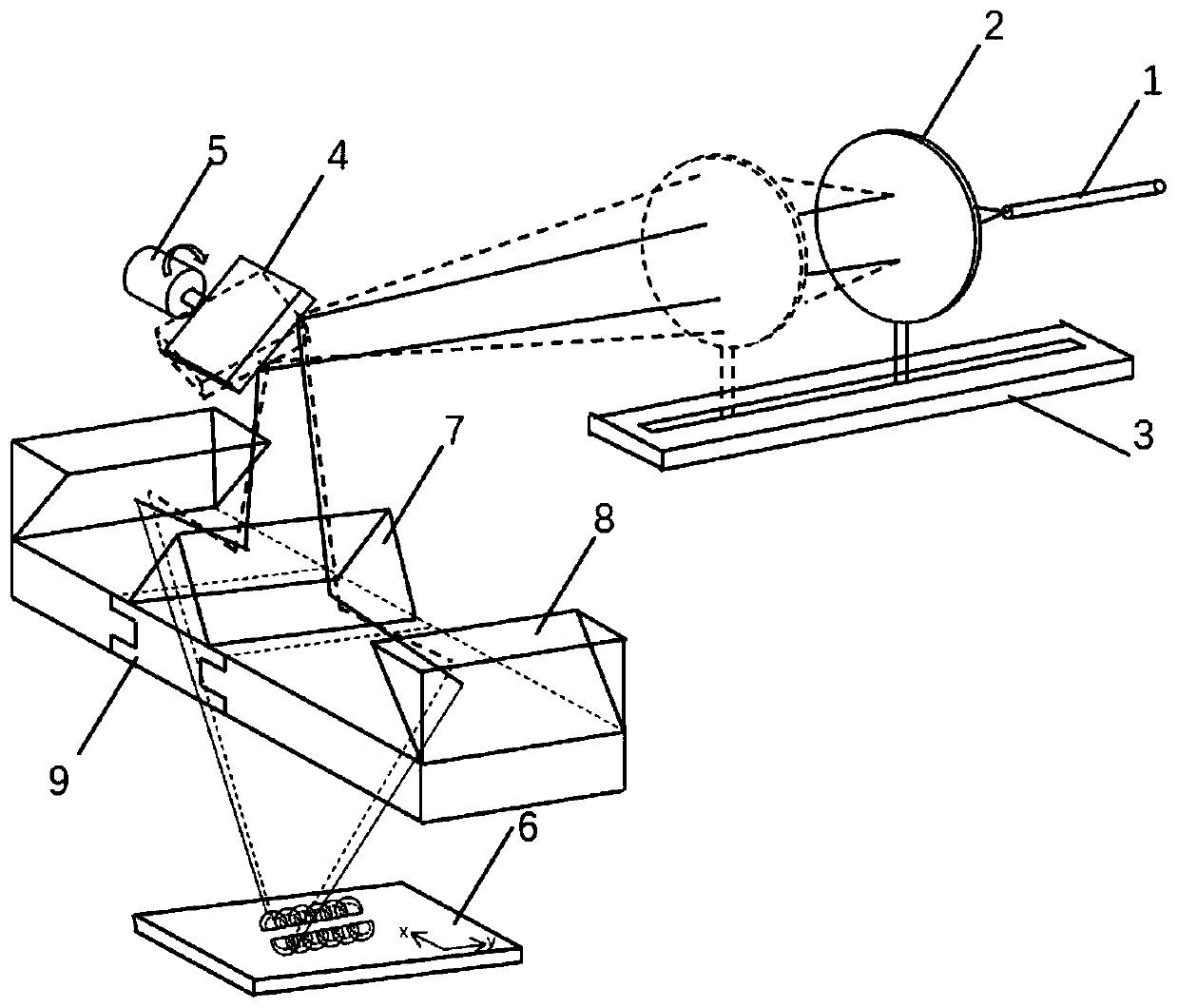

[0034] Such as figure 2 Another adjustable broadband laser processing optical system provided by the embodiment of the present invention includes a fiber laser 1, a focusing lens 2, a first motor and a guide rail 3 for controlling the movement of the focusing lens 2, a vibrating mirror 4, and a driving vibrating mirror Vibrating second motor 5, dichroic prism 7, reflector 8, sliding groove 9 and working surface 6 for controlling the position of dichroic prism 7, wherein dichroic prism 7, reflecting mirror 8, sliding groove for controlling the position of dichroic prism 7 9 form a spectroscopic device. The beam emitted by the fiber laser 1 enters the focusing lens 2 at a certain divergence angle. The beam is collimated and focused by the focusing lens 2 and then enters the galvanometer 4, and is reflected by the galvanometer 4 to the two beam-splitting facets of the beam-splitting prism 7. The beam is transmitted by the beam-splitting prism 7 After reflection and splitting, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com