Environment-friendly inflatable surfboard composite material and preparation method thereof

A composite material and surfboard technology, applied in the field of surfboards, can solve the problems of loose surfboards, inconvenience to carry, and high friction, and achieve the effects of good resilience, easy portability, and reduced resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The preparation method of the environment-friendly inflatable surfboard composite material comprises the following steps:

[0087] 1) Preparation of TPU fiber cloth reinforcement layer:

[0088] 1-1) According to the raw materials of the adhesive layer A / adhesive layer B, prepare the adhesive layer A coating solution / adhesive layer B coating solution with a viscosity of 15,000-25,000 cps, and mix the adhesive layer A coating solution / adhesive layer B coating solution Evenly coat the upper and lower sides of the base cloth layer by a coating machine to form a base cloth layer with adhesive layer A and adhesive layer B. The weight of adhesive layer A / adhesive layer B is 20-40gsm, and the process temperature of the coating machine The temperature is 100-130℃, and the curling speed is 4-6m / min;

[0089] 1-2) Mix and dry the raw materials of the TPU mask layer and the TPU bottom film layer respectively, and then respectively attach them to the adhesive layer A and the adhes...

Embodiment 1

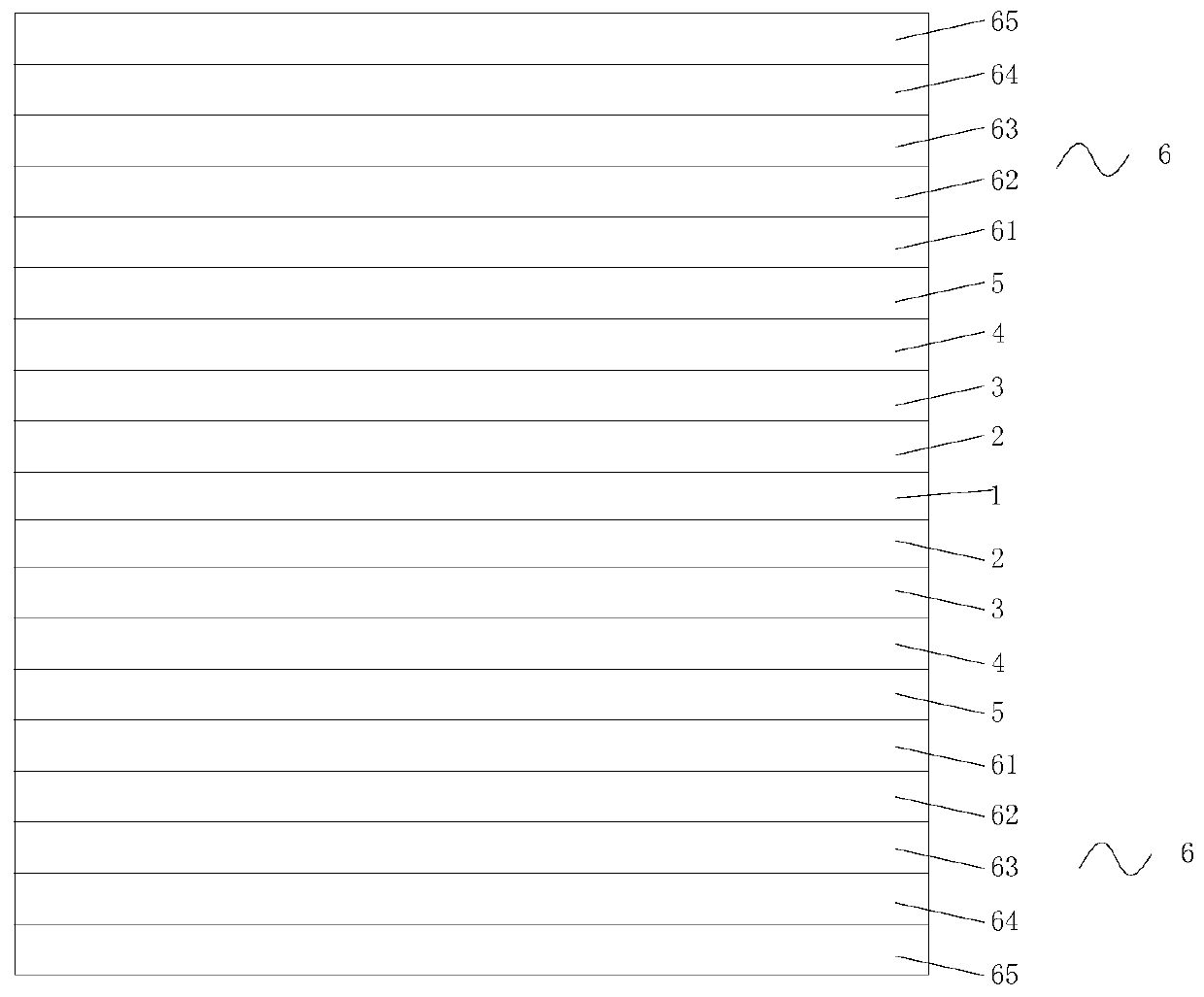

[0099] An environment-friendly inflatable surfboard composite material, which includes a high-strength space cloth layer, the two surfaces of the high-strength space cloth layer are sequentially provided with a second upper paste layer, a first upper paste layer, TPU Air-encapsulated layer, scratch coating and TPU fiber cloth reinforcement layer, the TPU fiber cloth reinforcement layer includes TPU mask layer, glue layer A, base cloth layer, glue layer B and TPU bottom film layer in sequence;

[0100] The high-strength space cloth layer is formed by high-strength polyester fiber space cloth, and the base cloth layer is formed by high-strength polyester fiber cloth.

[0101] The TPU mask layer in the TPU fiber cloth reinforcement layer is made of the following raw materials in parts by weight: 100 parts of TPU resin, 2.5 parts of TPU color masterbatch, 1.5 parts of antioxidant, 1.5 parts of anti-UV agent, 1.5 parts of antibacterial agent, Among them, the TPU masterbatch is comp...

Embodiment 2

[0119] An environment-friendly inflatable surfboard composite material, which includes a high-strength space cloth layer, the two surfaces of the high-strength space cloth layer are sequentially provided with a second upper paste layer, a first upper paste layer, TPU Air-encapsulated layer, scratch coating and TPU fiber cloth reinforcement layer, the TPU fiber cloth reinforcement layer includes TPU mask layer, glue layer A, base cloth layer, glue layer B and TPU bottom film layer in sequence;

[0120] The high-strength space cloth layer is formed by high-strength nylon fiber space cloth, and the base cloth layer is formed by high-strength nylon fiber cloth.

[0121] The TPU mask layer in the TPU fiber cloth reinforcement layer is made of the following raw materials in parts by weight: 100 parts of TPU resin, 1.5 parts of TPU color masterbatch, 3 parts of antioxidant, 2.5 parts of anti-UV agent, 1.8 parts of antibacterial agent, Wherein, the TPU color masterbatch is composed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com