Benzoquinone-based carbon dots/vinylpyrrolidone polymer rewritable room temperature phosphorescent composite material and its preparation method and application

A technology of vinylpyrrolidone and benzoquinone-based carbon dots is applied in the field of composite materials and organic room temperature phosphorescence materials, which can solve the problems of rewritable room temperature phosphorescence, which have not been reported, synthesis methods/cost limitations, etc. The effect of imprinting resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

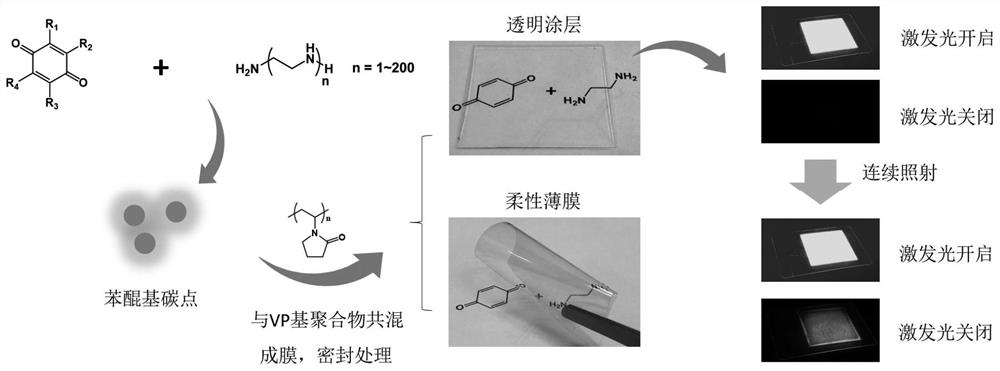

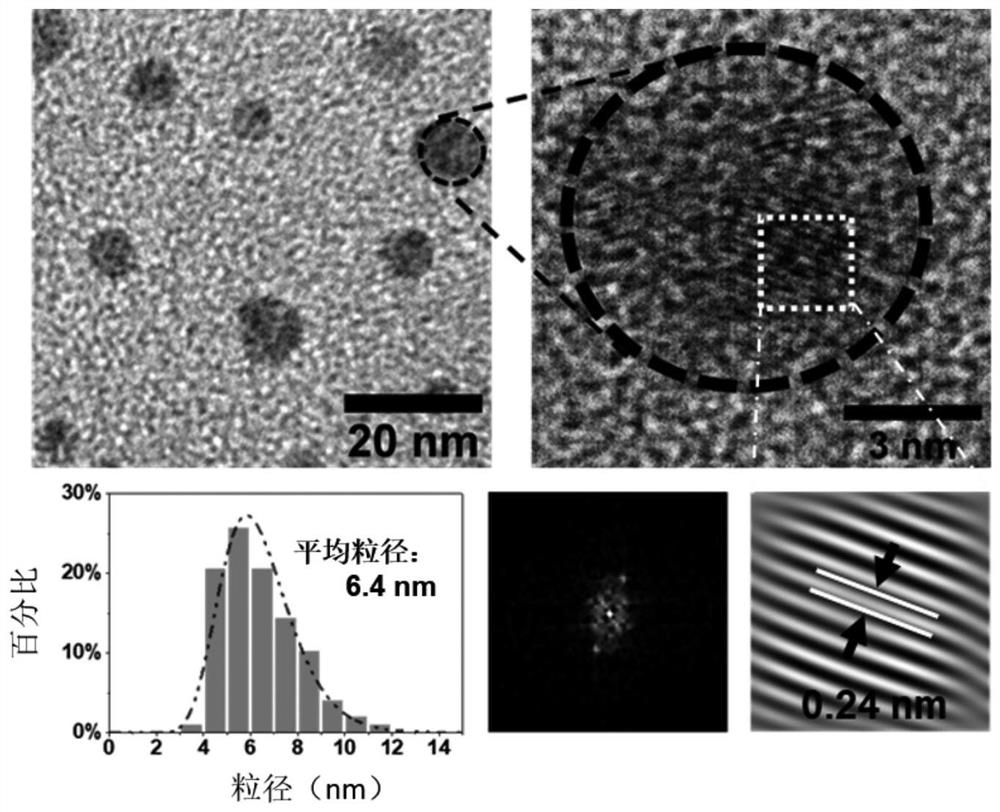

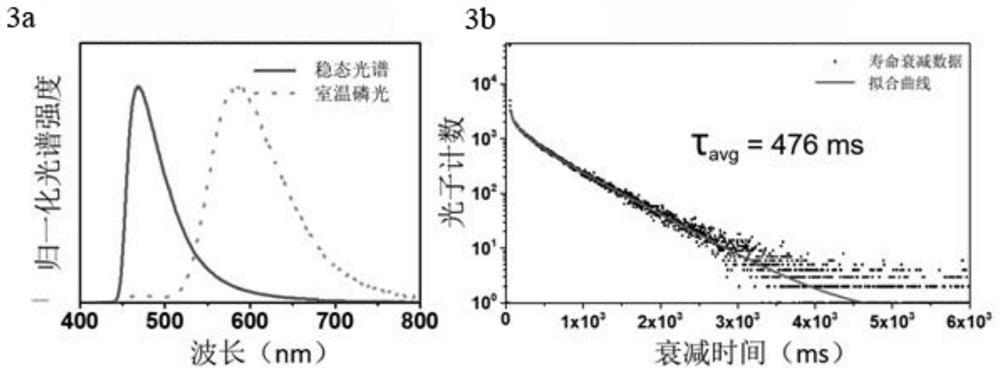

[0041] figure 1 Schematic diagram of the design and synthesis of benzoquinone-based carbon dots / vinylpyrrolidone-based polymer rewritable room-temperature phosphorescent composites, according to figure 1 Prepare the composite material. Weigh 2mmol of p-benzoquinone (216mg) and dissolve in 100mL of absolute ethanol to obtain a 20mM ethanol solution of p-benzoquinone, and add 4mmol of ethylenediamine (240mg, 1:4) to the above solution while stirring until uniformly dispersed. The mixed solution was transferred to a 200mL hydrothermal reaction kettle, sealed, heated at 120°C for 10h, and cooled to room temperature naturally. The product was collected by filtration and rotary evaporation to remove the solvent, and purified by silica gel column chromatography (eluent: 10% methanol / ethyl acetate mixed solvent) to obtain carbon point 1. The TEM (transmission electron microscope) morphology of carbon dot 1 is shown in figure 2 : The average particle size of carbon dots 1 is 6.4nm,...

Embodiment 2

[0047] Carbon dots 1 were prepared as described in Example 1. Weigh 5 mg of carbon dot 1 and 995 mg of polyvinylpyrrolidone with an average molecular weight of 360,000, and dissolve the two in 19 mL of deionized water under stirring to obtain a solution 1 with a solid content of 5%. On a 6cm round Petri dish mold, use a blast oven to heat at 40°C for 10h to remove most of the solvent, then transfer to a 130°C vacuum oven to dry under vacuum for 1h, and use a PET film with a thickness of 80μm to obtain material 2.

Embodiment 3

[0049] Carbon dots 1 were prepared as described in Example 1. Weigh 5 mg of carbon dot 1 and 995 mg of polyvinylpyrrolidone with an average molecular weight of 58,000, and dissolve the two in 19 mL of deionized water under stirring to obtain a solution 1 with a solid content of 5%. Measure 8 mL of the solution and drop-coat it on On a 6cm round Petri dish mold, use a forced air oven to heat at 40°C for 10h to remove most of the solvent, then transfer to a 130°C vacuum oven to dry under vacuum for 1h, and use a PET film with a thickness of 80μm to plastic seal the material 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com