A kind of inverse opal photonic crystal reusable thin film material and preparation method thereof

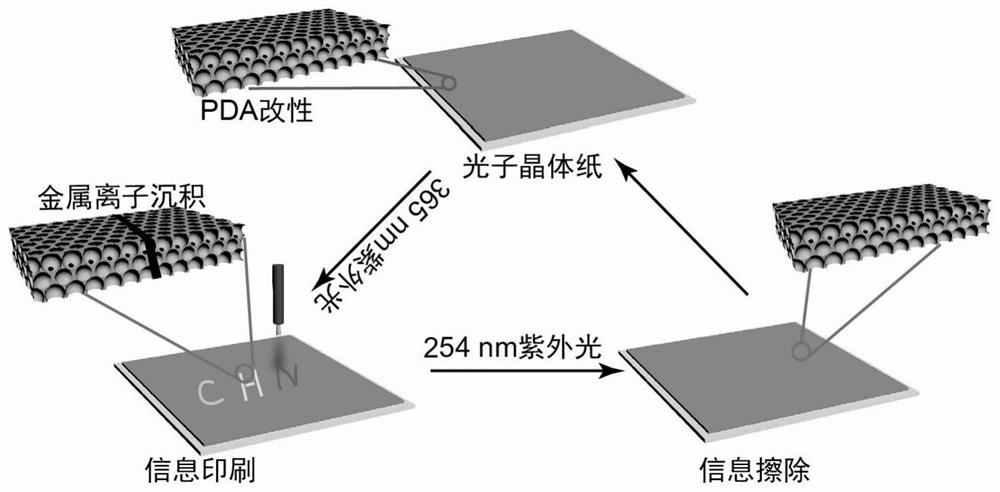

An inverse opal and photonic crystal technology, applied in the field of inverse opal photonic crystal reusable film materials and its preparation, can solve the problems of pattern burrs and low resolution of information display, etc., and achieve good use stability and excellent self-support The effect of performance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing an inverse opal photonic crystal reusable thin film material, the specific steps are as follows:

[0053] (1) Preparation of an opal photonic crystal template array:

[0054] Monodisperse silica nanospheres with a diameter of 200 nm were selected to prepare opal-type photonic crystal arrays; the monodisperse silica microspheres were assembled into three-dimensional ordered photonic crystal arrays by dipping and pulling self-assembly method; The monodispersed silica nano-microspheres are silica / ethanol dispersion liquid, and the mass fraction is 8%;

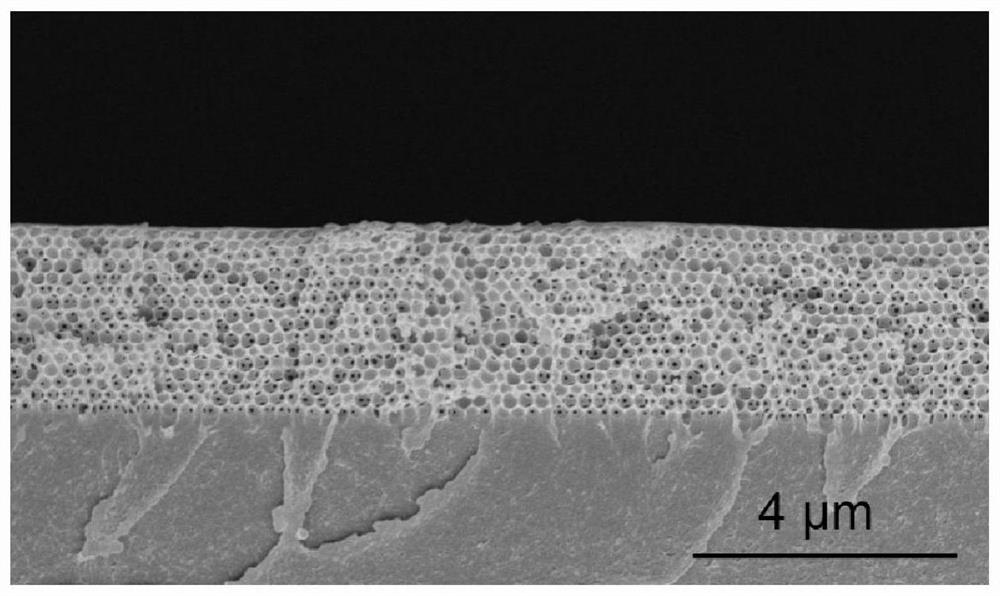

[0055] (2) Preparation of polymer inverse opal film:

[0056] The selected flexible polymer material is: polyvinylidene fluoride / N,N-dimethylformamide dispersion, the mass fraction is 8wt%;

[0057] The above-mentioned polyvinylidene fluoride / N,N-di-methylformamide dispersion liquid is uniformly infiltrated into the silicon dioxide photonic crystal array obtained in step (1), and the hydrofluoric ac...

Embodiment 2

[0066] A method for preparing an inverse opal photonic crystal reusable thin film material, the specific steps are as follows:

[0067] (1) Preparation of an opal photonic crystal template array:

[0068] The monodispersed cadmium sulfide nanospheres with a diameter of 250 nm are selected to prepare opal photonic crystal arrays; the monodispersed cadmium sulfide microspheres are assembled into a three-dimensional ordered photonic crystal array by a vertical deposition self-assembly method; The dispersed cadmium sulfide nano-microspheres are cadmium sulfide / anhydrous ethanol dispersion liquid, the mass fraction is 10%;

[0069] (2) Preparation of polymer inverse opal film:

[0070] The flexible polymer material is: polyethersulfone / N,N-dimethylacetamide dispersion, the mass fraction is 10wt%;

[0071] The above-mentioned polyethersulfone / N,N-dimethylacetamide dispersion liquid is uniformly infiltrated into the cadmium sulfide photonic crystal array obtained in step (1), and t...

Embodiment 3

[0079] A method for preparing an inverse opal photonic crystal reusable thin film material, the specific steps are as follows:

[0080] (1) Preparation of an opal photonic crystal template array:

[0081] Monodisperse zinc sulfide nanospheres with a diameter of 220 nm were selected to prepare opal photonic crystal arrays; the monodisperse zinc sulfide microspheres were assembled into three-dimensional ordered photonic crystal arrays by spin coating self-assembly method;

[0082] The monodispersed zinc sulfide nano-microspheres are zinc sulfide / absolute ethanol dispersion, and the mass fraction is 12%;

[0083] (2) Preparation of polymer inverse opal film:

[0084] The selected flexible polymer material is: polymethyl methacrylate / tetrahydrofuran dispersion, the mass fraction is 6wt%;

[0085] The above-mentioned polymethyl methacrylate / tetrahydrofuran dispersion is uniformly infiltrated into the zinc sulfide photonic crystal array obtained in step (3), and the opal template ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com