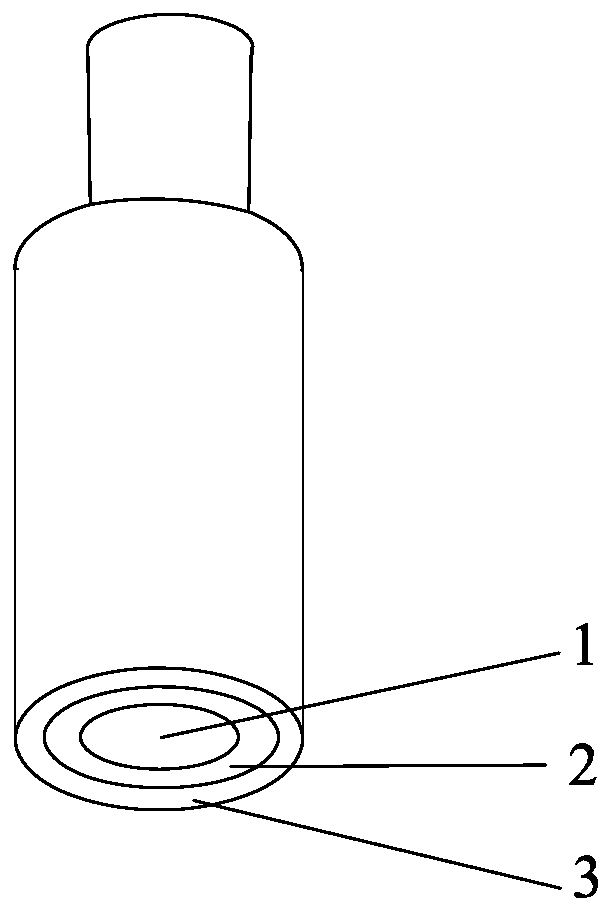

Special rubber sleeve composition for grinding and polishing of mobile phone glass

A composition and rubber sleeve technology, applied in grinding/polishing equipment, grinding devices, manufacturing tools, etc., can solve the problems of inability to achieve hole edge grinding, difficult to meet mass production, and difficult to guarantee product quality, etc. The effect of meeting the requirements of green environmental protection and sustainable development, reducing tool production costs and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 A special rubber sleeve composition for mobile phone glass grinding and polishing, including the following components in parts by mass: 60 parts of natural rubber and 40 parts of EPDM rubber.

[0028] The preparation method of described composition comprises the steps:

[0029] After mixing natural rubber and EPDM according to the formula, they are placed in a rubber mixer and kneaded to obtain rubber; then the rubber is placed in a vulcanizer and vulcanized by a thermal vulcanization process to obtain the described Special rubber sleeve composition for mobile phone glass grinding and polishing.

[0030] The vulcanizing agent is sulfur, the amount of sulfur is 20% of the total amount of rubber mixing, the pressurized range is 180kgf / cm2, and the temperature is raised to 220° C. for 95 seconds.

Embodiment 2

[0031] Example 2 A special rubber sleeve composition for mobile phone glass grinding and polishing, including the following components in parts by mass: 90 parts of natural rubber and 10 parts of EPDM rubber.

[0032] The preparation method of described composition comprises the steps:

[0033] After mixing natural rubber and EPDM according to the formula, they are placed in a rubber mixer and kneaded to obtain rubber; then the rubber is placed in a vulcanizer and vulcanized by a thermal vulcanization process to obtain the described Special rubber sleeve composition for mobile phone glass grinding and polishing.

[0034] The vulcanizing agent is sulfur, the amount of sulfur is 20-40% of the total amount of rubber mixing, the pressure range is 160kgf / cm2, and the temperature is raised to 230°C for 86 seconds.

Embodiment 3

[0035] Example 3 A special rubber sleeve composition for mobile phone glass grinding and polishing, including the following components in parts by mass: 80 parts of natural rubber and 20 parts of EPDM rubber. The preparation method of described composition comprises the steps:

[0036] After mixing natural rubber and EPDM according to the formula, they are placed in a rubber mixer and kneaded to obtain rubber; then the rubber is placed in a vulcanizer and vulcanized by a thermal vulcanization process to obtain the described Special rubber sleeve composition for mobile phone glass grinding and polishing.

[0037] The vulcanizing agent is sulfur, the amount of sulfur is 40% of the total amount of rubber mixing, the pressurized range is 200kgf / cm2, and the temperature is raised to 225° C. for 95 seconds.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap